Silicone rubber halogen-free flame retardant as well as preparation method and application thereof

A technology of silicone rubber and flame retardant, which is applied in the field of flame retardants, can solve the problems of large addition amount, poor heat resistance, and high price, and achieve the effects of good heat resistance, easy precipitation, and high flame retardant efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] A preparation method for preparing an environmentally friendly non-halogen flame retardant comprises the following steps:

[0025] Step 1: Put the piperazine pyrophosphate to be processed into a high-speed mixer, start stirring, heat up to 125°C, add an appropriate amount of modification treatment agent, continue stirring for 10 minutes, and then discharge and cool;

[0026] Step 2: Transfer the material obtained in step 1 to an ultra-fine pulverizer for pulverization, the obtained material is packaged and weighed, marked as material A, and reserved for later use;

[0027] Step 3: Put the melamine cyanurate to be processed into the high-speed mixer, start the mixing, add an appropriate amount of modification agent in the mixing process, continue to mix for 10 minutes, and then transfer it to the ultrafine pulverizer for pulverization. , The obtained material is packaged and weighed, marked as material B, and reserved for later use;

[0028] Step 4: Put the materials A,...

Embodiment 1

[0031] Take 30 grams of material A, 52 grams of material B, 10 grams of aluminum diethyl hypophosphite, 8 grams of zinc borate, and 1.5 grams of silicone oil dispersant, and put them into a small mixer to fully stir and mix evenly to obtain silicone rubber halogen-free flame retardant agent.

[0032] Take 100 grams of raw silicone rubber with a shore hardness of 40 degrees, mix it on an open mill, and add 50 grams of flame retardant and 20 grams of white carbon black in stages. agent, mix thoroughly and evenly.

[0033] Transfer the above-mentioned mixed rubber into a flat vulcanizer that has been preheated to 120°C, and vulcanize it for 3 to 5 minutes to obtain a flame-retardant silicone rubber, which can be used for flame-retardant and other performance tests.

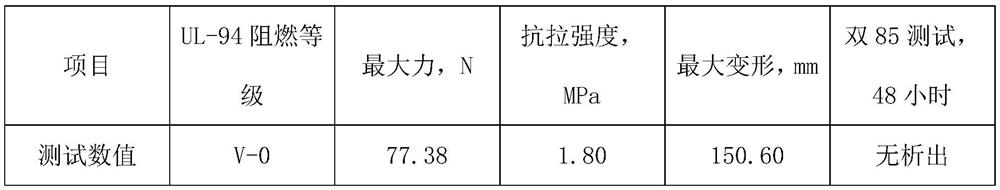

[0034] The flame retardant silicone rubber product of this example can reach the V-0 flame retardant level of 1.6 mm UL-94.

[0035] The relevant performance test results of the flame retardant test pieces are show...

Embodiment 2

[0038] Take 40 grams of the A material, 48 grams of the B material, 6 grams of aluminum diethyl hypophosphite, 6 grams of zinc borate, 1.5 grams of silicone oil dispersant, put into a small mixer, stir and mix evenly, that is, silicone rubber halogen-free flame retardant .

[0039] Take 100 grams of raw silicone rubber with a shore hardness of 40 degrees, mix it on an open mill, and add 65 grams of flame retardant and 20 grams of white carbon black in stages, mix thoroughly and evenly, and then add 1 gram of bis-disulfide. agent, mix thoroughly and evenly.

[0040] Transfer the above-mentioned mixed rubber into a flat vulcanizer that has been preheated to 120°C, and vulcanize it for 3 to 5 minutes to obtain a flame-retardant silicone rubber, which can be used for flame-retardant and other performance tests.

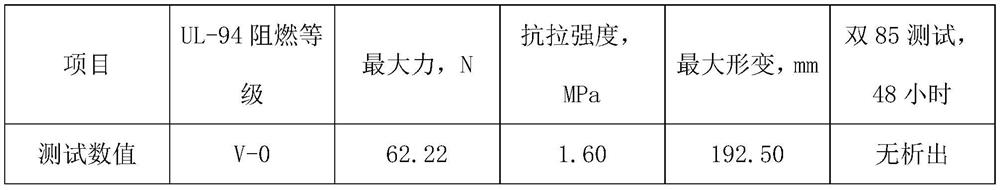

[0041] The flame retardant silicone rubber product of this example can reach the V-0 flame retardant level of 1.0 mm UL-94.

[0042] The relevant performance test resul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com