Short-process bainite hot working die and preparation method thereof

A hot work die and bainite technology, applied in the field of die manufacturing, can solve the problems of long manufacturing cycle, energy consumption and time consuming of hot work die, and achieve the effect of improving hardness and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

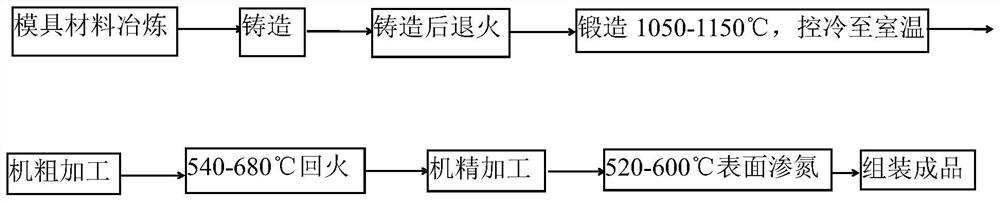

[0054] The short-flow bainite hot working die of this embodiment is composed of the following elements by mass percentage: C: 0.50%; Si: 0.20%; Mn: 1.00%; W: 2.10%; Mo: 3.50%; V: 0.50% ; Co: 0.60%; RE: 0.01%, P: 0.01%, S: 0.003%, and the rest are Fe and inevitable impurities. The preparation steps of the bainite hot work die are as follows:

[0055] (1) Weigh the alloy raw material according to the composition of the die steel, pour it into a steel ingot after being smelted in an electric furnace at 1400 °C, and then anneal at 700 °C for 8 hours after electroslag remelting to obtain a die steel billet.

[0056] (2) After heating the die steel billet to 1150°C for 8 hours, perform multi-directional forging, control the final forging temperature to 990°C, and control the cooling of the forged material in the heat treatment furnace at a cooling rate of 1°C / s Controlled cooling to room temperature to obtain a bainite-structured die steel material with a hardness of 405HV30.

[0...

Embodiment 2

[0063] The short-flow bainite hot working die of this embodiment is composed of the following elements by mass percentage: C: 0.55%; Si: 0.22%; Mn: 1.30%; W: 2.50%; Mo: 4.50%; V: 0.80% ; Co: 0.90%; RE: 0.05%, P: 0.01%, S: 0.01%, and the rest are Fe and inevitable impurities.

[0064] The preparation steps of the bainite hot work die are as follows:

[0065] (1) Weigh the alloy raw material according to the composition of the die steel, pour it into a steel ingot after being smelted in an electric furnace at 1400 °C, and then anneal at 700 °C for 8 hours after electroslag remelting to obtain a die steel billet.

[0066] (2) After heating the die steel billet to 1150°C for 8 hours, perform multi-directional forging, control the final forging temperature to 1010°C, and control the cooling of the forged material in the heat treatment furnace at a cooling rate of 2°C / s Controlled cooling to room temperature to obtain a bainite-structured die steel material with a hardness of 425HV...

Embodiment 3

[0073] The short-flow bainite hot working die of this embodiment is composed of the following elements by mass percentage: C: 0.60%; Si: 0.20%; Mn: 1.50%; W: 3.00%; Mo: 5.0%; V: 1.00% ; Co: 1.10%; RE: 0.07%, P: 0.01%, S: 0.02%, and the rest are Fe and inevitable impurities.

[0074] The preparation steps of the bainite hot work die are as follows:

[0075] (1) Weigh the alloy raw material according to the composition of the die steel, pour it into a steel ingot after being smelted in an electric furnace at 1400 °C, and then anneal at 700 °C for 8 hours after electroslag remelting to obtain a die steel billet.

[0076] (2) After heating the die steel billet to 1050°C for 8 hours, perform multi-directional forging, control the final forging temperature to 1000°C, and control the cooling of the forged material in the heat treatment furnace at a cooling rate of 2.5°C / s Controlled cooling to room temperature to obtain a bainite-structured die steel material with a hardness of 436H...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com