Preparation method of super-hydrophobic wear-resistant coating containing buffer structure

A technology of wear-resistant coating and buffer structure, applied in coatings, chemical instruments and methods, and devices for coating liquids on surfaces, etc., can solve the problems of poor corrosion resistance of coatings and limited pipelines, and achieve excellent wear resistance. And the effect of corrosion resistance, easy operation and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

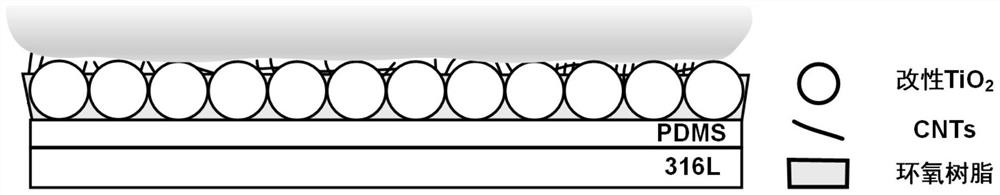

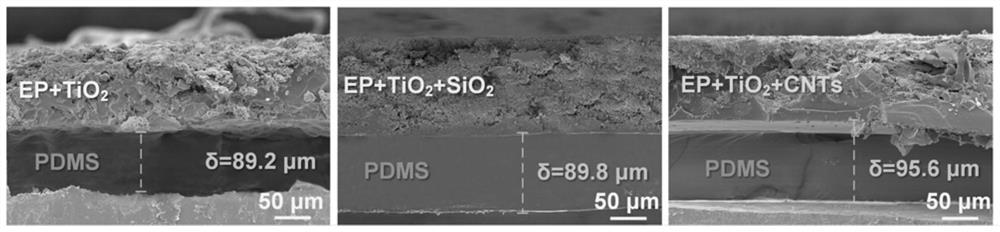

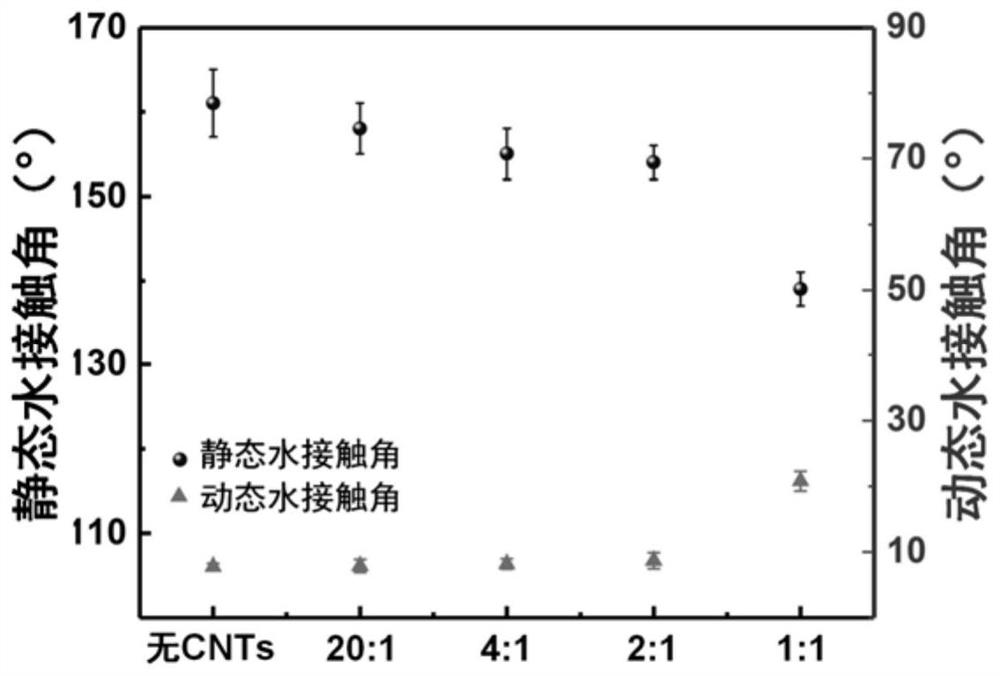

[0043] A preparation method of a superhydrophobic wear-resistant coating containing a buffer structure, comprising the following steps:

[0044] Step 1: Preparation of modified TiO 2 particles

[0045]Disperse 0.2 g of lauric acid powder in 15 ml of absolute ethanol, and perform ultrasonic treatment for 10 min to obtain a lauric acid solution. 300 μL of tetraethyl titanate was slowly dropped into the lauric acid solution, and the first magnetic stirring was carried out. The rotating speed of the first magnetic stirring was 400 rpm and the time was 20 min. Then, 200 μL of deionized water and 10 μL of HCl were sequentially added to the solution, and the concentration of HCl was 0.2 mol / L, and then a second magnetic stirring was performed. The rotational speed of the second magnetic stirring was 700 rpm and the time was 20 min. TiO 2 solution. Finally, the modified TiO 2 The solution is centrifuged in a centrifuge to obtain modified TiO 2 particles. The rotational speed of...

Embodiment 2

[0057] A preparation method of a superhydrophobic wear-resistant coating containing a buffer structure, comprising the following steps:

[0058] Step 1: Preparation of modified TiO 2 particles

[0059] Disperse 0.2 g of lauric acid powder in 20 ml of absolute ethanol, and perform ultrasonic treatment for 10 min to obtain a lauric acid solution. 320 μL of tetraethyl titanate was slowly dropped into the lauric acid solution, and the first magnetic stirring was carried out. The rotating speed of the first magnetic stirring was 400 rpm and the time was 30 min. Then, 200 μL of deionized water and 10 μL of HCl were added to the solution in turn, and the concentration of HCl was 0.3 mol / L, and then a second magnetic stirring was performed. The rotation speed of the second magnetic stirring was 800 rpm and the time was 20 min. TiO 2 solution. Finally, the modified TiO 2 The solution is centrifuged in a centrifuge to obtain modified TiO 2 particles. The rotational speed of the c...

Embodiment 3

[0067] A preparation method of a superhydrophobic wear-resistant coating containing a buffer structure, comprising the following steps:

[0068] Step 1: Preparation of modified TiO 2 particles

[0069] Disperse 0.2 g of lauric acid powder in 10 ml of absolute ethanol, and perform ultrasonic treatment for 10 min to obtain a lauric acid solution. 300 μL of tetraethyl titanate was slowly dropped into the lauric acid solution, and the first magnetic stirring was carried out. The rotating speed of the first magnetic stirring was 400 rpm and the time was 30 min. Then, 250 μL of deionized water and 10 μL of HCl were added to the solution in turn, and the concentration of HCl was 0.2 mol / L, and then a second magnetic stirring was performed. The rotation speed of the second magnetic stirring was 800 rpm and the time was 15 min. TiO 2 solution. Finally, the modified TiO 2 The solution is centrifuged in a centrifuge to obtain modified TiO2 particles. The rotational speed of the cen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| corrosion potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com