Preparation method and application of modified Al2O3/perfume composite material with controllable slow release performance

A technology of composite materials and slow-release performance, applied in the fields of application, food science, tobacco, etc., can solve the problems of low release rate and slow release rate, and achieve the effects of controllable slow-release performance, simple method, and easy popularization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Tobacco stems were soaked in 6% HCL.

[0036] (2) Gradient dehydration of (1) with absolute ethanol.

[0037] (3) Weighing 37.5% of hydrated aluminum nitrate is dissolved in deionized water, heated and stirred to a transparent state solution.

[0038] (4) Use 2moL / L of ammonia water to titrate (3), and continue stirring, stop the titration when the pH reaches 8.5, and continue stirring for 2h at the same time.

[0039] (5) Soak (2) in (4) for 50h.

[0040] (6) (5) was filtered, and the precipitate was taken and dried naturally at room temperature.

[0041] (7) The dried (6) was further dried in a 90° C. oven for 30 hours.

[0042](8) The dried (7) is placed in a muffle furnace for calcination, and the calcination temperature is 550°C.

[0043] (9) Al is obtained after calcination 2 O 3 Modified material.

[0044] (10) Weigh 0.4% ethyl maltol, add 100g Al 2 O 3 The modified material was placed on a magnetic stirrer and stirred for 4 hours, and centrifuged to...

Embodiment 2

[0048] TiO was prepared by the method of implementation 1 2 Modified material, the remaining steps are the same as in Example 1.

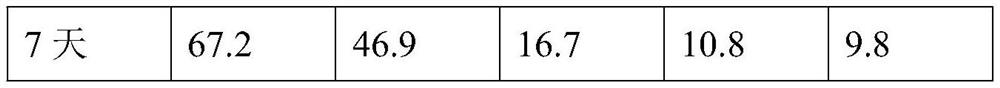

[0049] Determination of Modified TiO 2 / Ethyl maltol composite material on flavor loading, the results are shown in Table 1.

Embodiment 3

[0051] SiO was prepared by the method of implementation 1 2 Modified material, the remaining steps are the same as in Example 1.

[0052] Determination of modified SiO 2 / Ethyl maltol composite material on flavor loading, the results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com