Switched reluctance motor torque ripple and bus current ripple suppression method

A switched reluctance motor and torque pulsation technology, which is applied in the direction of motor generator control, AC motor control, electronic commutation motor control, etc., can solve the problems of shortened life, large impact current of supporting capacitors, and inability to take into account bus current pulsation, etc. problem, to achieve the effect of simple control logic, direct suppression of torque ripple, and obvious suppression effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The following in conjunction with the accompanying drawings and specific examples, the technical solution of the present invention is described in detail. The motor used in the example is a 1kW three-phase 12 / 8 pole switched reluctance motor.

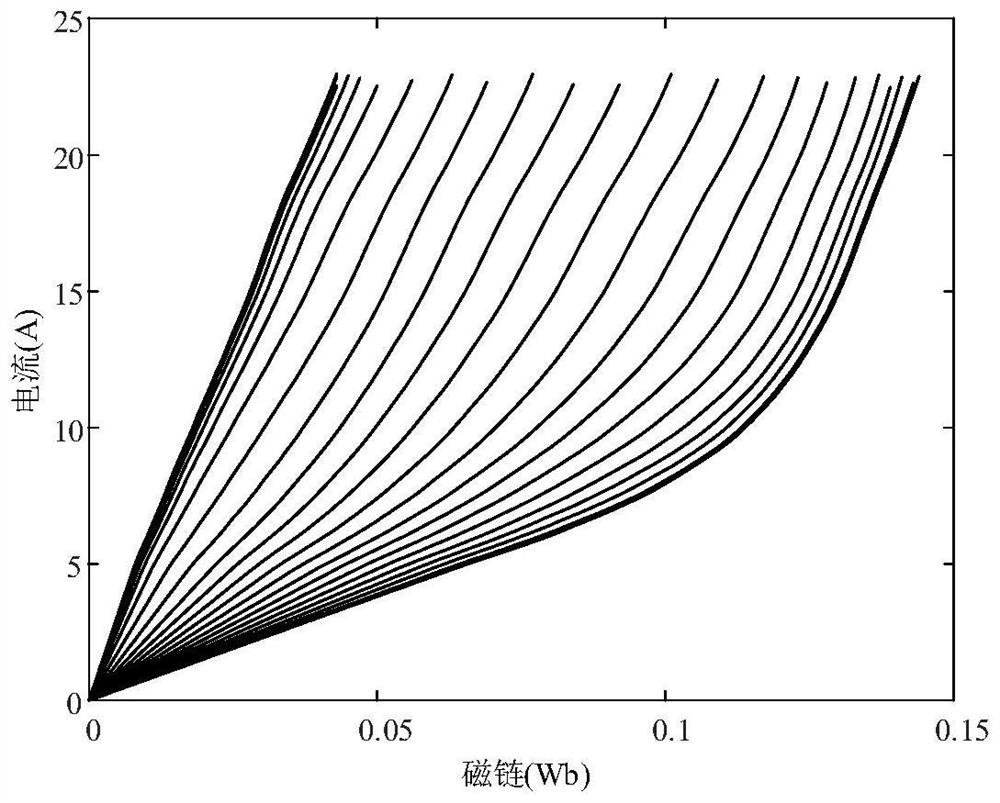

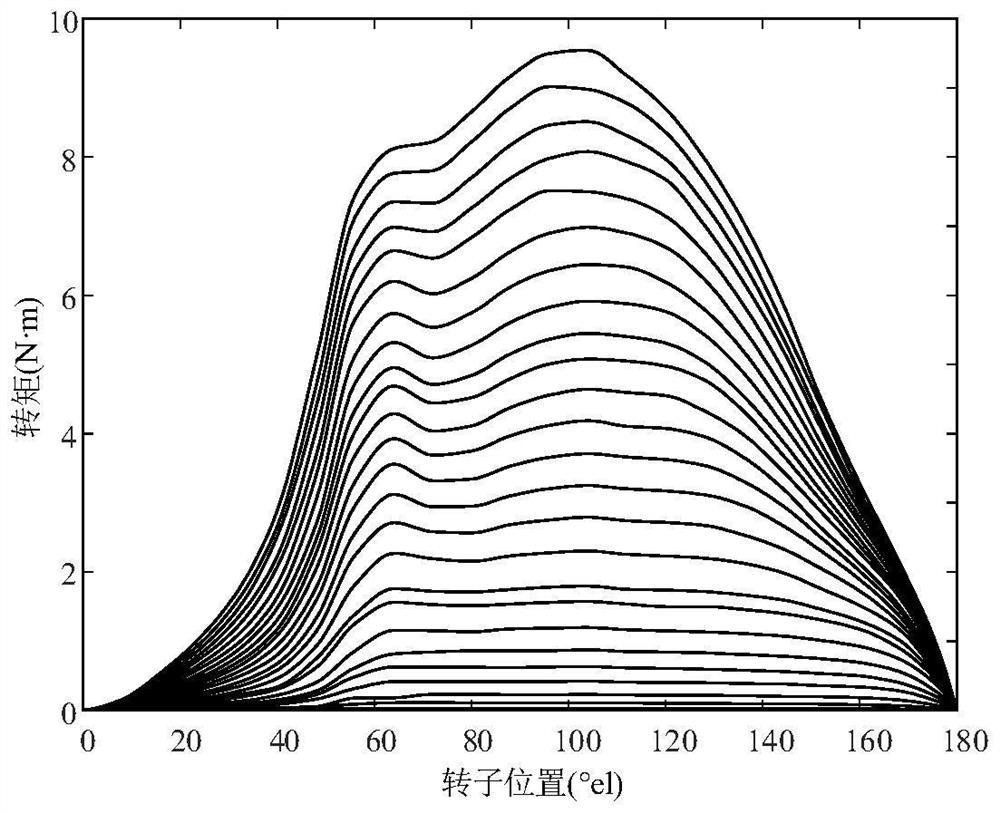

[0047] Step 1: Experimentally measure the flux characteristics and torque characteristics of the switched reluctance motor; obtain the flux characteristics ψ (i, θ) of the switched reluctance motor by the rotor fixation clamping method, wherein the ψ is the flux, i is the current, and θ is the position; the current lookup table i (ψ, θ) is constructed by interpolation method. On the basis of the flux characteristics, the torque data table T(i,θ) is constructed according to the bias of the position of the magnetic resonance energy. Characteristics of the flux, current and torque such as Figure 1-3 as shown. The formula for calculating magnetic common energy W′ is shown in equation (1), and the formula for torque T is shown in equation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com