Hot melt adhesive for bonding high-temperature-resistant food bag and preparation method of hot melt adhesive

A food bag, high temperature resistant technology, applied in the directions of polymer adhesive additives, non-polymer adhesive additives, adhesives, etc. The degree of mixing, the effect of improving adhesion and stability, and improving dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

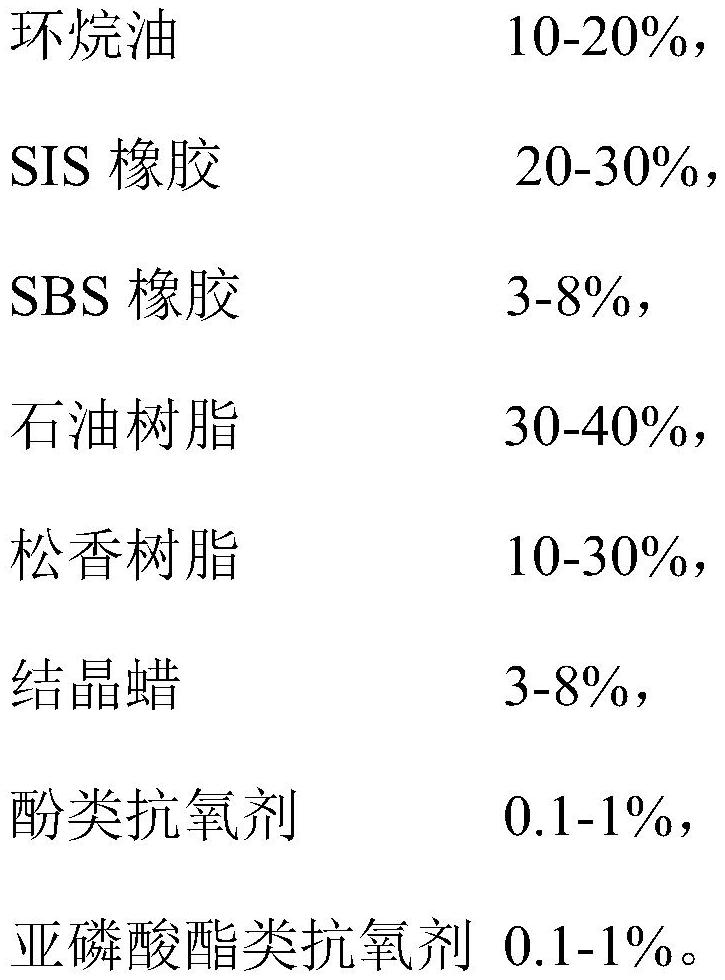

[0031] A hot-melt adhesive for bonding high-temperature food bags, comprising the following components by weight percentage:

[0032]

[0033]

[0034] The naphthenic oil has a viscosity of 120-160 cps at 40°C.

[0035] The styrene content in the SIS rubber is 30%.

[0036] The styrene content in the SBS rubber is 40%.

[0037] The petroleum resin is C5 petroleum resin, and the softening point of the petroleum tackifying resin is 100°C;

[0038] The softening point of the rosin resin is 100°C.

[0039] The crystalline wax is Fetowax; the melting point of the crystalline wax is 100°C.

[0040] The phenolic antioxidant is tetrakis[beta-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid]pentaerythritol ester;

[0041] The phosphite antioxidant is tris[2.4-di-tert-butylphenyl]phosphite.

[0042] The preparation method of the hot-melt adhesive for bonding high temperature resistant food bags comprises the following steps:

[0043] 1) heating and stirring the petroleum re...

Embodiment 2

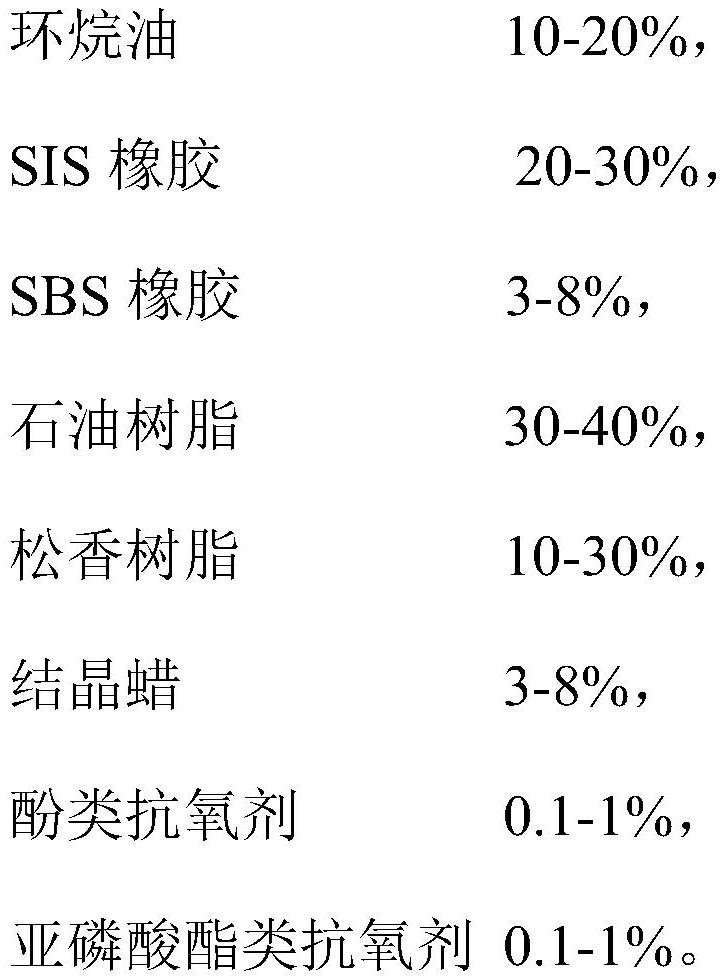

[0046] A hot-melt adhesive for bonding high-temperature food bags, comprising the following components by weight percentage:

[0047]

[0048] The naphthenic oil has a viscosity of 120-160 cps at 40°C.

[0049] The styrene content in the SIS rubber is 38%.

[0050] The styrene content in the SBS rubber is 38%.

[0051] The petroleum resin is a DCPD resin, and the softening point of the petroleum tackifying resin is 100°C;

[0052] The softening point of the rosin resin is 100°C.

[0053] The crystalline wax is Feito wax; the melting point of the crystalline wax is 100°C.

[0054] The phenolic antioxidant is tetrakis[beta-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid]pentaerythritol ester;

[0055] The phosphite antioxidant is tris[2.4-di-tert-butylphenyl]phosphite.

[0056] The preparation method of the hot-melt adhesive for bonding high temperature resistant food bags comprises the following steps:

[0057] 1) heating and stirring the petroleum resin and rosin re...

Embodiment 3

[0060] A hot-melt adhesive for bonding high-temperature food bags, comprising the following components by weight percentage:

[0061]

[0062] The naphthenic oil has a viscosity of 120-160 cps at 40°C.

[0063] The styrene content in the SIS rubber is 32%.

[0064] The styrene content in the SBS rubber is 40%.

[0065] The petroleum resin is a C5 / C9 copolymer resin, and the softening point of the petroleum tackifying resin is 100°C;

[0066] The softening point of the rosin resin is 100°C.

[0067] The crystalline wax is Fetowax; the melting point of the crystalline wax is 100°C.

[0068] The phenolic antioxidant is tetrakis[beta-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid]pentaerythritol ester;

[0069] The phosphite antioxidant is tris[2.4-di-tert-butylphenyl]phosphite.

[0070] The preparation method of the hot-melt adhesive for bonding high temperature resistant food bags comprises the following steps:

[0071] 1) heating and stirring the petroleum resin and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com