Method for processing jujube-wood doubling dies for wire production

A processing method, jujube wood technology, applied in the direction of wood processing equipment, impregnated wood, manufacturing tools, etc., can solve the problems of unstable service life and other problems, and achieve the advantages of preventing metal powder from adhering, low production cost, corrosion resistance, wear resistance and ignition point Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

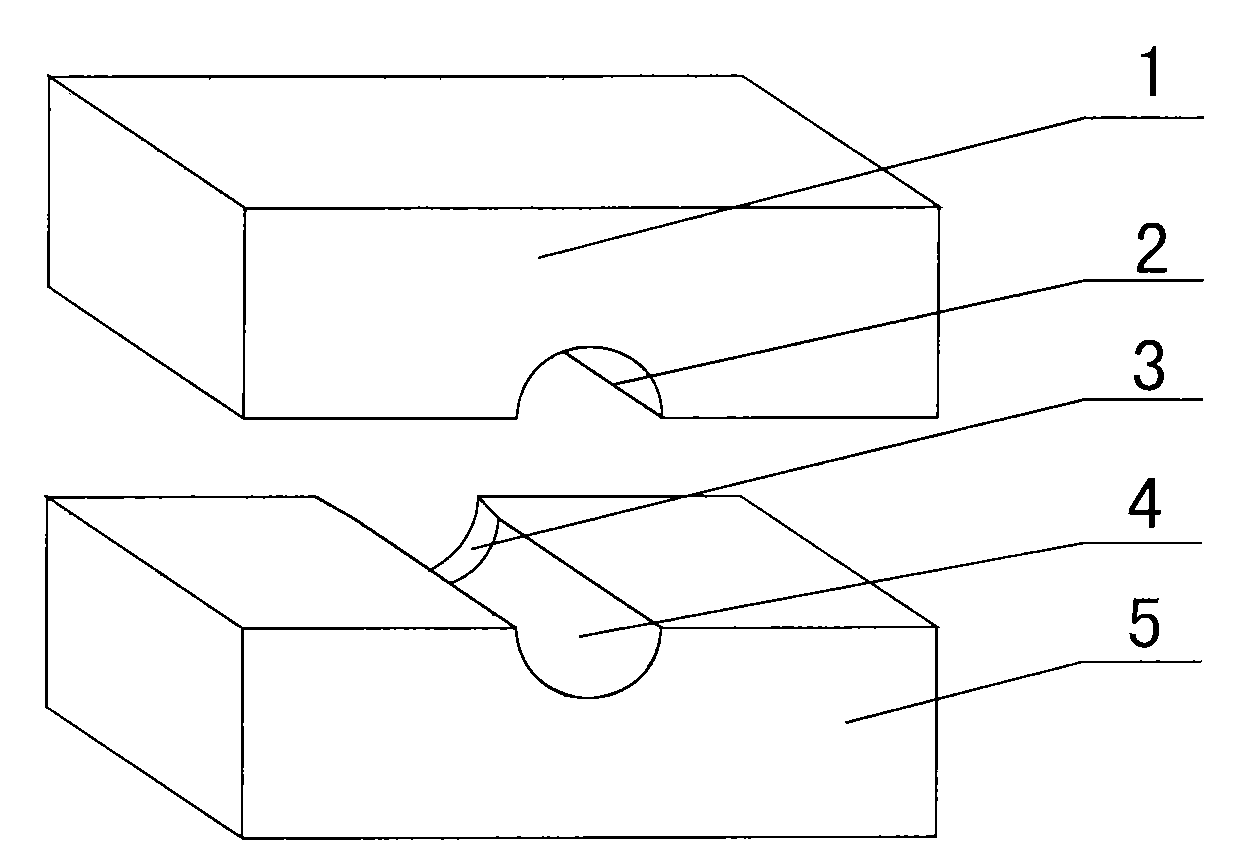

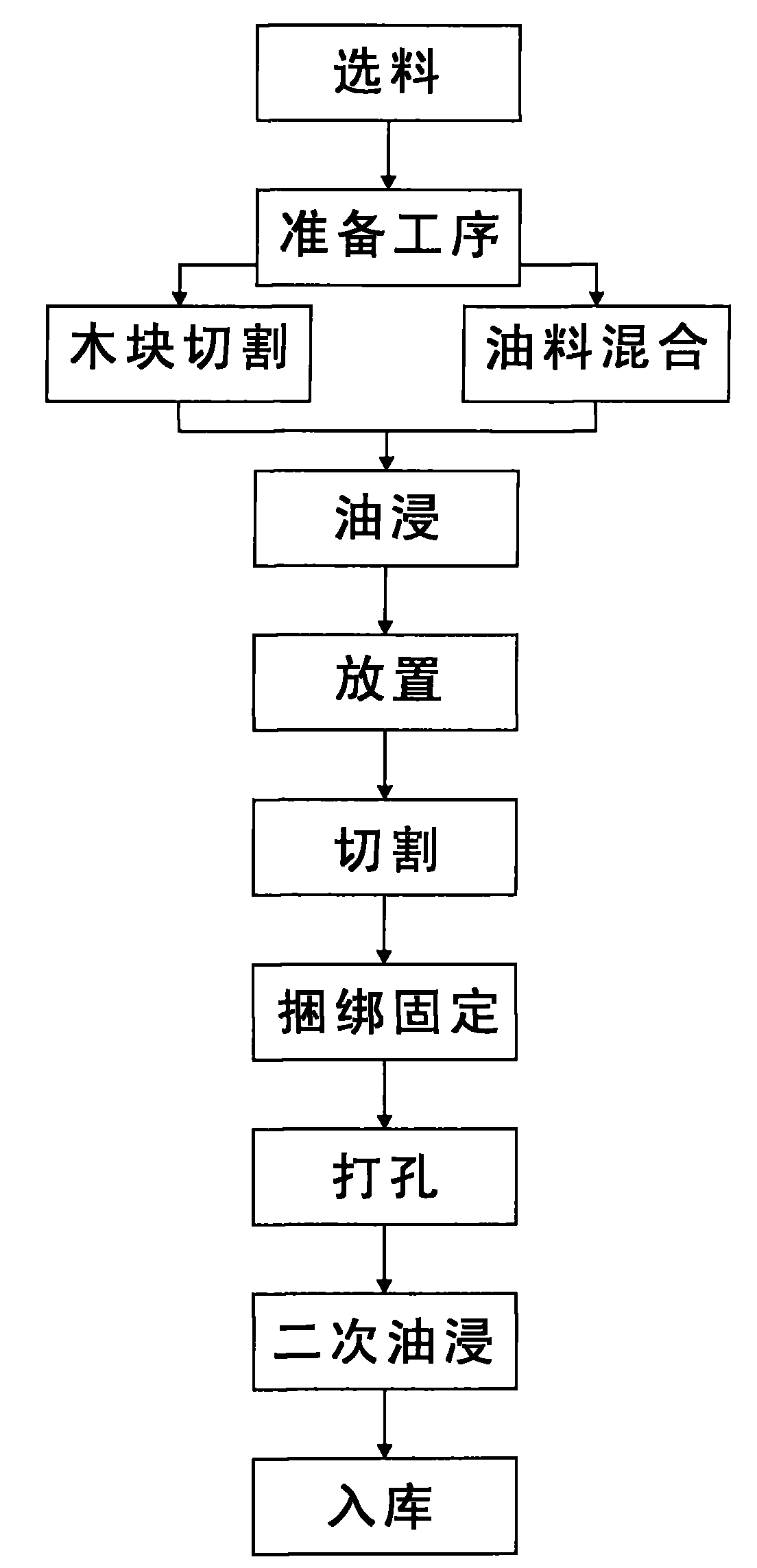

[0030] Now in conjunction with accompanying drawing, the present invention is described in detail:

[0031] Such as figure 1 , 2 Shown, a kind of processing method of jujube wood doubling mold for the production of aluminum wire comprises the following steps;

[0032] a. Material selection:

[0033] Choose high-quality jujube wood with no scars, no branches, no cracks, no insects, and good quality, and the selected jujube wood should have a certain water content; Caused by the shrinkage difference between the radial and chord directions near the pith center, the splitting occurs at the early stage of drying, and the cracks appear only on the surface of the end of the wood at first. As the wood dries, the cracks can expand toward the pith center and longitudinally. It is difficult to prevent it when dry, so jujube wood with a certain water content is preferred in the present invention.

[0034] b. Preparation process, including wood block cutting and oil mixing:

[0035] 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com