Amorphous nanocrystalline alloy strip and preparation method thereof

An amorphous nanocrystalline, alloy ribbon technology, applied in the direction of magnetic materials, magnetic objects, circuits, etc., can solve the problems of coiling interruption, failure to eliminate or reduce broadband shrinkage stress, strip fracture, etc., to ensure the effect of cooling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

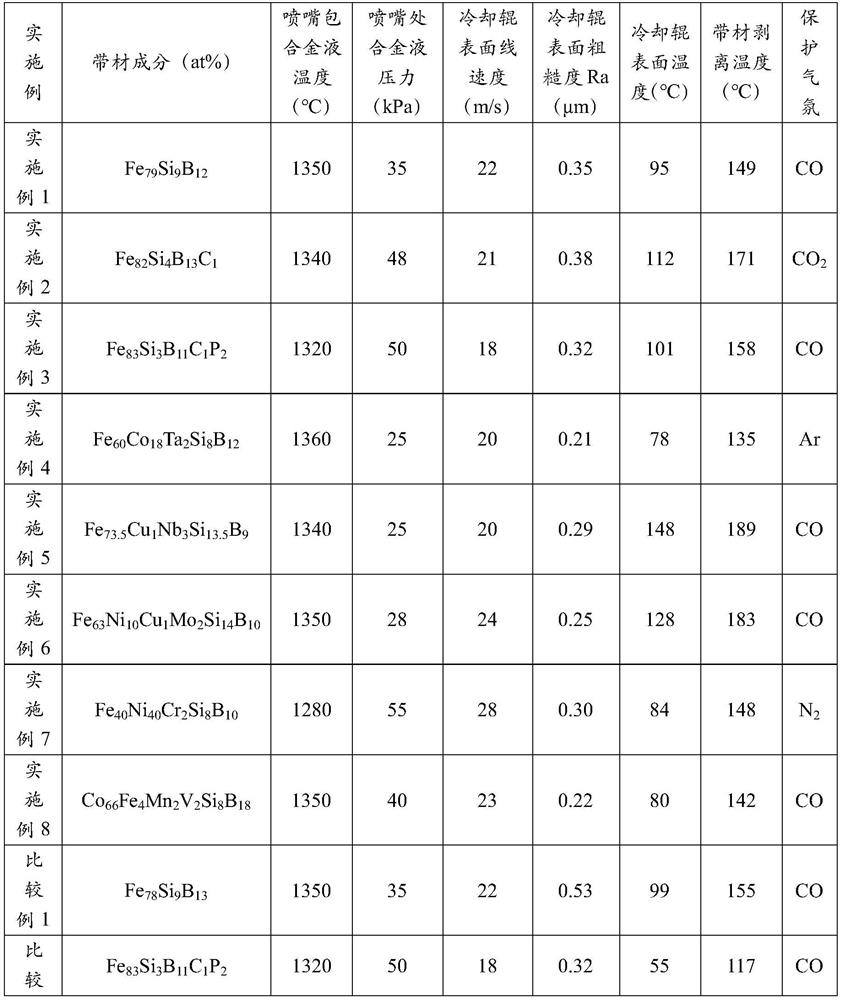

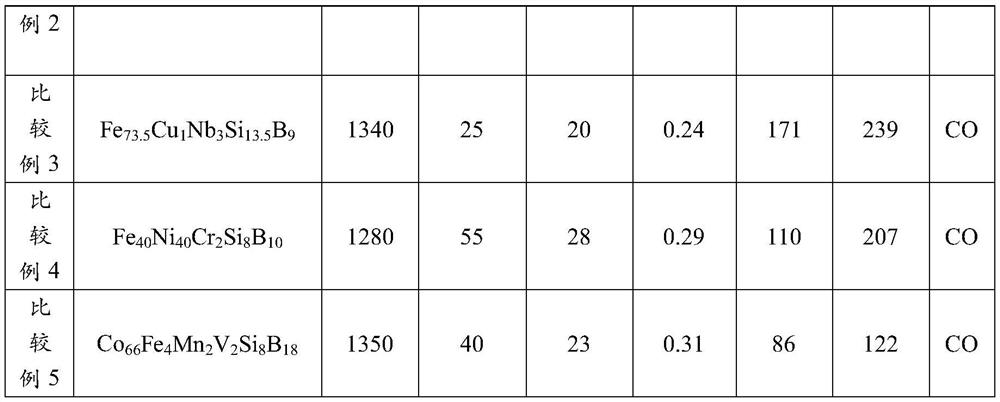

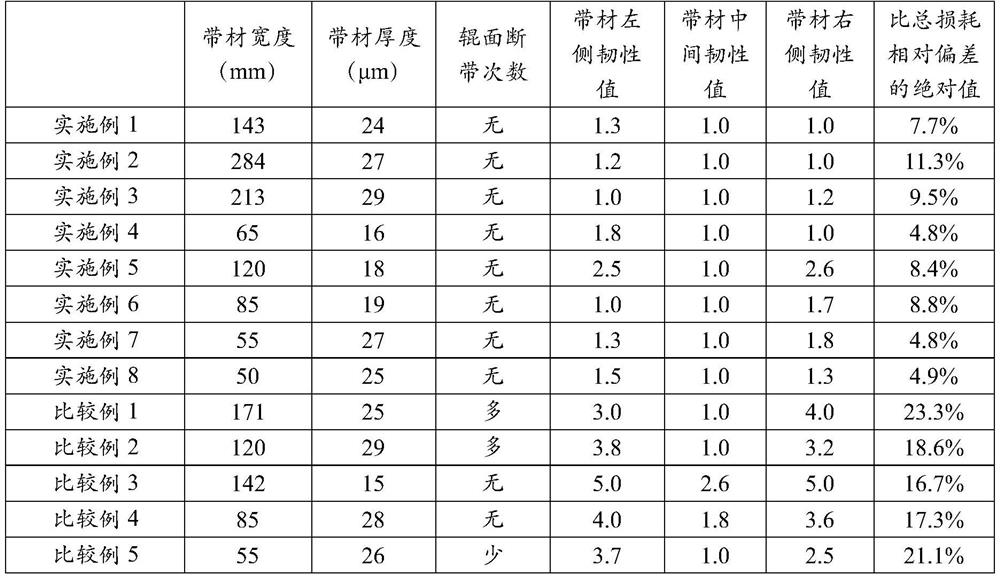

[0038] In the embodiment of the present invention, the iron-based amorphous nanocrystalline alloy strip is prepared by a planar flow rapid solidification process, and the raw materials used are industrial-grade pure elements or alloys. The specific preparation method is as follows:

[0039] First, a certain ratio of raw materials is melted into alloy liquid in a smelting furnace, and the smelted alloy liquid can be poured into the tundish for temperature adjustment and production rhythm buffering. Then, the molten alloy is poured into a nozzle bag with a slit nozzle at the bottom. The alloy liquid in the nozzle package flows out of the nozzle, spreads on the outer peripheral surface of the high-speed rotating copper alloy cooling roll under the nozzle, and is rapidly cooled to form a continuous strip with an amorphous or nanocrystalline structure.

[0040] In the present embodiment, the raw material composition of the amorphous nanocrystalline alloy strip is Fe 79 Si 9 B 12...

Embodiment 2

[0045] In the embodiment of the present invention, the iron-based amorphous nanocrystalline alloy strip is prepared by a planar flow rapid solidification process, and the raw materials used are industrial-grade pure elements or alloys. The specific preparation method is as follows:

[0046] First, a certain ratio of raw materials is melted into alloy liquid in a smelting furnace, and the smelted alloy liquid can be poured into the tundish for temperature adjustment and production rhythm buffering. Then, the molten alloy is poured into a nozzle bag with a slit nozzle at the bottom. The alloy liquid in the nozzle package flows out of the nozzle, spreads on the outer peripheral surface of the high-speed rotating copper alloy cooling roll under the nozzle, and is rapidly cooled to form a continuous strip with an amorphous or nanocrystalline structure.

[0047] In the present embodiment, the raw material composition of the amorphous nanocrystalline alloy strip is Fe 82 Si 4 B 13...

Embodiment 3

[0052] In the embodiment of the present invention, the iron-based amorphous nanocrystalline alloy strip is prepared by a planar flow rapid solidification process, and the raw materials used are industrial-grade pure elements or alloys. The specific preparation method is as follows:

[0053] First, a certain ratio of raw materials is melted into alloy liquid in a smelting furnace, and the smelted alloy liquid can be poured into the tundish for temperature adjustment and production rhythm buffering. Then, the molten alloy is poured into a nozzle bag with a slit nozzle at the bottom. The alloy liquid in the nozzle package flows out of the nozzle, spreads on the outer peripheral surface of the high-speed rotating copper alloy cooling roll under the nozzle, and is rapidly cooled to form a continuous strip with an amorphous or nanocrystalline structure.

[0054] In the present embodiment, the raw material composition of the amorphous nanocrystalline alloy strip is Fe 83 Si 3 B 11...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com