Coated sulfide solid electrolyte material and preparation method and application thereof

A solid electrolyte and sulfide technology, which is applied to active material electrodes, circuits, positive electrodes, etc., can solve the problem of reducing the interface compatibility between the sulfide solid electrolyte and the positive electrode material, limiting the coating method and the industrial application of the coating material. , the coating method is cumbersome and other problems, to achieve the effect of significant coating effect, improved interface stability, and low coating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

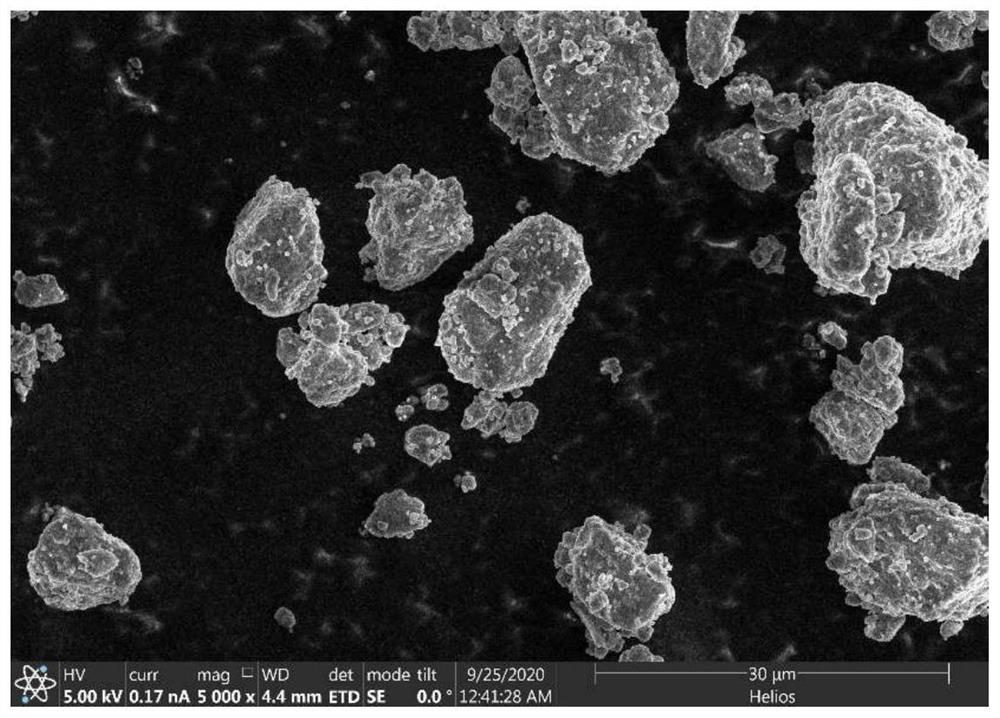

[0050] (1) In a glove box with an argon atmosphere, LiSiPSCl sulfide solid electrolyte and LiFSI organic lithium salt were thoroughly mixed in a mortar at a mass ratio of 100:1 to obtain 505 mg of mixed powder.

[0051] (2) Transfer the mixed powder into a high-energy ball mill jar, and then add zirconia ball milling beads, the mass ratio of the ball milling beads to the mixed powder is 70:1, and the total mass is 35.5 g.

[0052] (3) Set the high-energy ball milling program at a rotational speed of 500 rpm / min, and each cycle is divided into 10 minutes of ball milling time and 5 minutes of resting time, and 48 cycles are performed for a total of 12 hours of high-energy ball milling.

[0053] (4) Collect the coated electrolyte powder in an argon atmosphere glove box to obtain a coated sulfide solid electrolyte material.

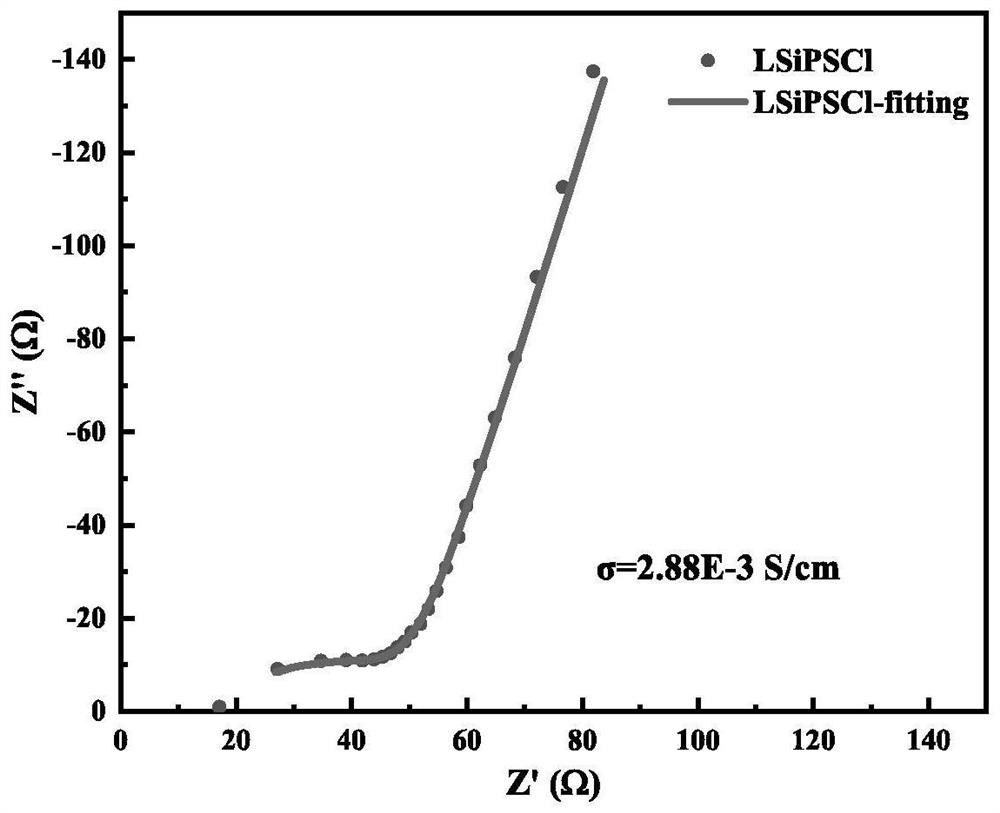

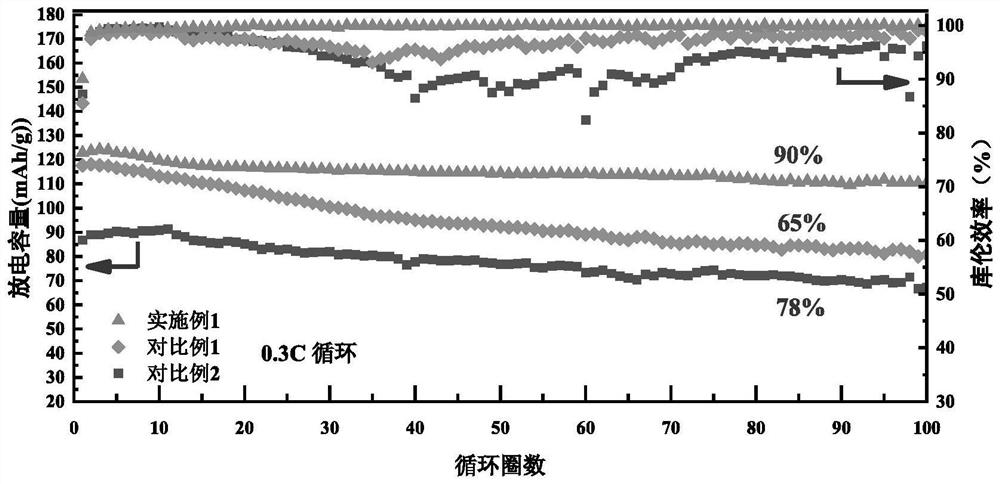

[0054] The electrochemical performance of the prepared coated sulfide solid electrolyte material was tested. The experimental program mainly consists of four...

Embodiment 2

[0065] (1) In an argon atmosphere glove box, LiSiPSCl sulfide solid electrolyte and LiFSI were thoroughly mixed at a mass ratio of 200:1 to obtain 502.5 mg of a mixed powder sample.

[0066] (2) Transfer the mixed powder into a high-energy ball mill jar, and then add zirconia ball milling beads, the mass ratio of the ball milling beads to the mixed powder is 70:1, and the total mass is 35.5 g.

[0067] (3) Set the high-energy ball milling program at a rotational speed of 500 rpm / min, and each cycle is divided into 10 minutes of ball milling time and 5 minutes of resting time, and 48 cycles are performed for a total of 12 hours of high-energy ball milling.

[0068] (4) Collect the coated electrolyte powder in an argon atmosphere glove box to obtain a coated sulfide solid electrolyte material.

[0069] The same electrochemical performance test scheme and electrolyte ionic conductivity test scheme as in Example 1 were used. It can be obtained that the first-cycle discharge speci...

Embodiment 3

[0071] (1) In an argon atmosphere glove box, LiSiPSCl sulfide solid electrolyte and LiFSI were thoroughly mixed at a mass ratio of 60:1 to obtain 510 mg of a mixed powder sample.

[0072] (2) Transfer the mixed powder into a high-energy ball mill jar, and then add zirconia ball milling beads, the mass ratio of the ball milling beads to the mixed powder is 70:1, and the total mass is 35.5 g.

[0073] (3) Set the high-energy ball milling program at a rotational speed of 500 rpm / min, and each cycle is divided into 10 minutes of ball milling time and 5 minutes of resting time, and 48 cycles are performed for a total of 12 hours of high-energy ball milling.

[0074] (4) Collect the coated electrolyte powder in an argon atmosphere glove box to obtain a coated sulfide solid electrolyte material.

[0075] The same electrochemical performance test scheme and electrolyte ionic conductivity test scheme as in Example 1 were used. We can obtain that the first discharge specific capacity o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com