Method of synthesizing lithium manganate material for lithium ion battery

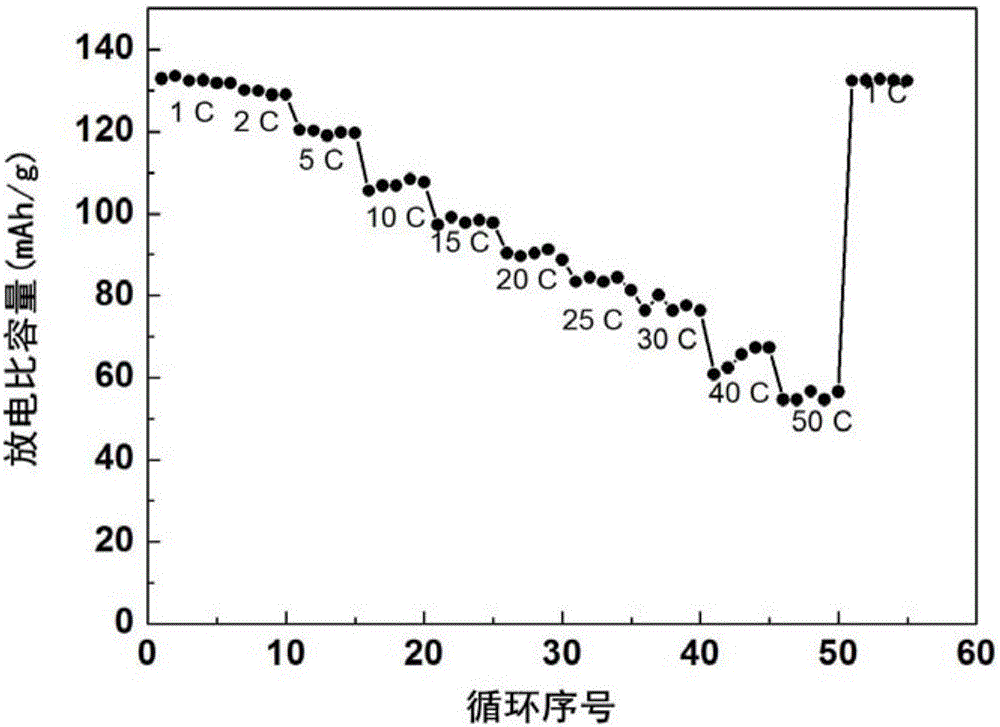

A lithium-ion battery technology using lithium manganese oxide, which is applied to battery electrodes, secondary batteries, circuits, etc., can solve the problems of inability to form a spherical shape, low self-discharge rate, and high heating rate, so as to improve cycle performance and capacity fading , the effect of crystal structure stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A kind of synthetic method of lithium manganese oxide material for lithium ion battery, comprises the following steps:

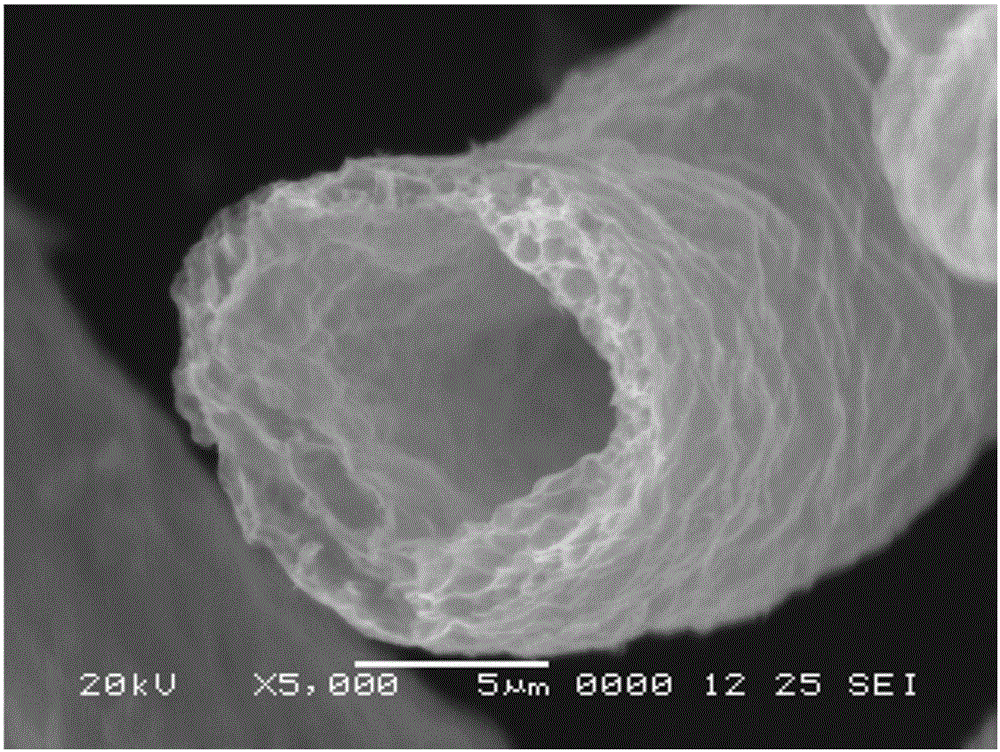

[0033] a) Collect waste cigarette butts, wash and dry at 60°C;

[0034] b) Mix 0.2mol / L manganese nitrate solution and 0.1mol / L lithium nitrate solution according to the manganese-lithium molar ratio of 2:1, and obtain the mixed solution after ultrasonic treatment;

[0035] c) Soak 10 g of the cigarette butts treated in step a in the mixed solution obtained in step b, make the mixed solution cover the cigarette butts, take out after soaking and dry; soak the discarded cigarette butts in the mixed solution for 1 hour, then dry The temperature is 60°C;

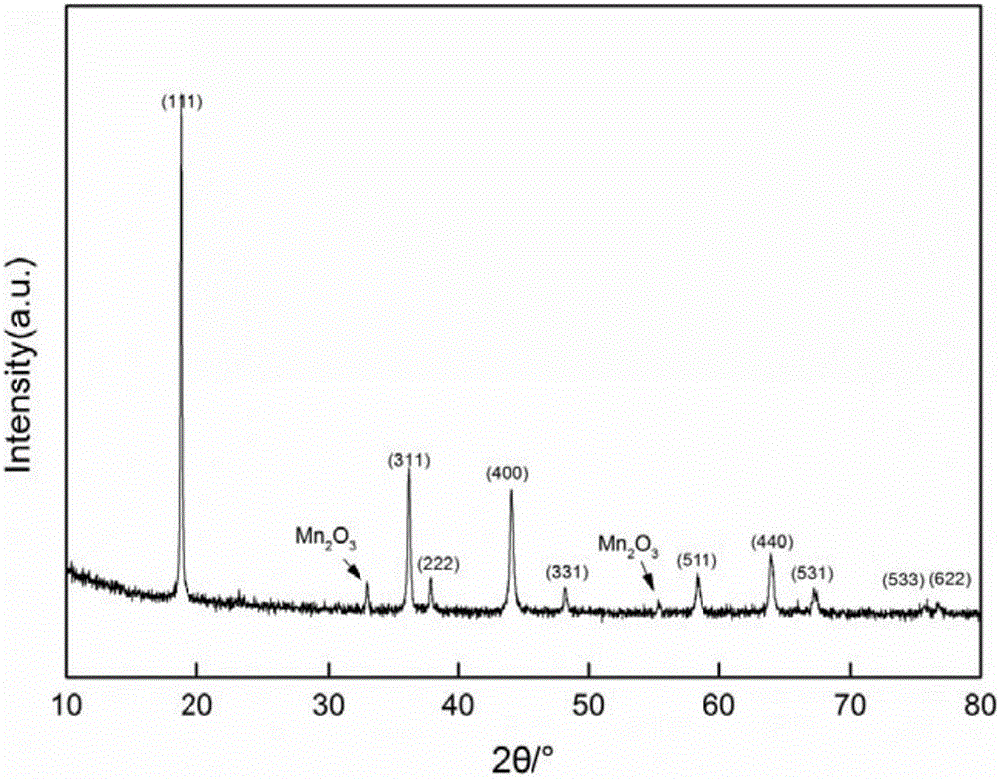

[0036] d) Calcining the cigarette butt treated in step c in an air atmosphere at 700° C. for 3 hours to obtain a lithium manganate material; the heating rate during calcination is 1° C. per minute.

Embodiment 2

[0038] A kind of synthetic method of lithium manganese oxide material for lithium ion battery, comprises the following steps:

[0039] a) Collect waste cigarette butts, wash and dry at 50°C;

[0040] b) Mix 0.1mol / L manganese acetate solution and 0.1mol / L lithium nitrate solution according to the ratio of manganese to lithium molar ratio of 2:1, and obtain the mixed solution after ultrasonic treatment;

[0041] c) Soak 3 g of the cigarette butts treated in step a in the mixed solution obtained in step b, make the mixed solution cover the cigarette butts, take out after soaking and dry; soak the discarded cigarette butts in the mixed solution for 0.5 hours, then dry The temperature is 50°C;

[0042] d) Calcining the cigarette butt treated in step c in an air atmosphere at 600° C. for 2 hours to obtain a lithium manganate material; the heating rate during calcination is 1° C. per minute.

Embodiment 3

[0044] A kind of synthetic method of lithium manganese oxide material for lithium ion battery, comprises the following steps:

[0045] a) Collect waste cigarette butts, wash and dry at 60°C;

[0046] b) Mix 4mol / L manganese sulfate solution and 2mol / L lithium sulfate solution according to the manganese-lithium molar ratio of 2:1, and obtain the mixed solution after ultrasonic treatment;

[0047] c) Soak 15 g of the cigarette butts treated in step a in the mixed solution obtained in step b, make the mixed solution cover the cigarette butts, take out after soaking and dry; soak the discarded cigarette butts in the mixed solution for 1.5 hours, then dry The temperature is 60°C;

[0048] d) Calcining the cigarette butt treated in step c in an air atmosphere at 650° C. for 5 hours to obtain a lithium manganate material; the heating rate during calcination is 3° C. per minute.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com