Long-acting tailing passivator capable of being cured at normal temperature as well as preparation method and application of long-acting tailing passivator

A technology of room temperature solidification and passivation agent, which is applied in the field of acid mine wastewater treatment and metal mine tailings passivation to achieve the effects of cost economy, cost reduction and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

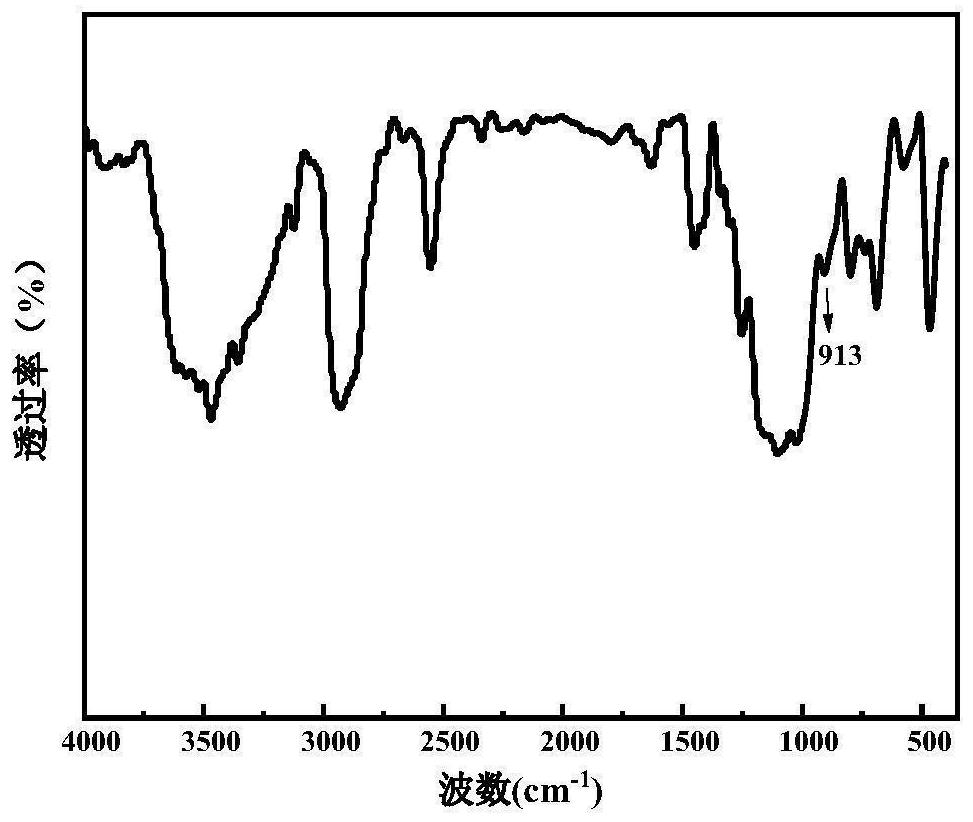

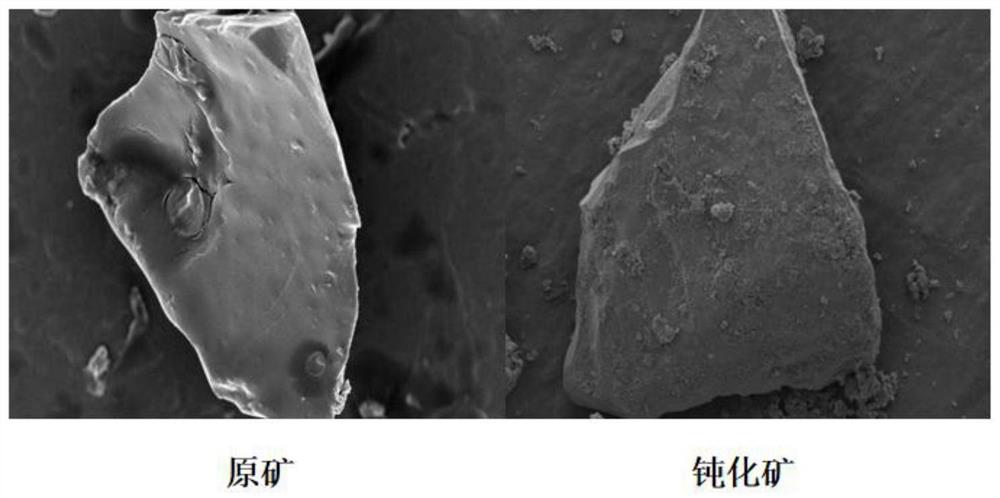

Method used

Image

Examples

Embodiment 1

[0056] (1) Stir and dissolve sodium carbonate in deionized water, add dibutyl phosphate according to the molar ratio of dibutyl phosphate to sodium is 1:1, to obtain a 0.1mol / L sodium organophosphate solution; configure 0.033mol / L chlorinated For cerium solution, add an equal volume of cerium chloride solution to the sodium organophosphate solution dropwise, stir rapidly at room temperature, continue to stir for 2 hours after the addition, wash 5 times with deionized water, separate by suction filtration, and dry at 60°C for 24 hours to obtain Cerium organophosphate (Ce(dbp) 3 ) into a pulverizer to grind the solid to obtain restoration agent granules.

[0057] (2) Add γ-glycidyl etheroxytrimethoxysilane into a water / ethanol mixed solvent with a volume ratio of 1:2 to configure a 4wt% silane solution, adjust the pH to 5 with 0.1mol / L hydrochloric acid, and Magnetic stirring at 500 rpm at room temperature for 4 hours to carry out hydrolysis reaction to obtain a silanol solutio...

Embodiment 2

[0062] (1) Stir and dissolve sodium carbonate in deionized water, add dibutyl phosphate according to the molar ratio of dibutyl phosphate to sodium is 1:1, to obtain a 0.1mol / L sodium organophosphate solution; configure 0.033mol / L chlorinated For cerium solution, add an equal volume of cerium chloride solution to the sodium organophosphate solution dropwise, stir rapidly at room temperature, continue stirring for 2 hours after the addition, wash with deionized water for 7 times, separate by suction filtration, and dry at 70°C for 12 hours to obtain Cerium organophosphate (Ce(dbp) 3 ) into a pulverizer to grind the solid to obtain restoration agent granules.

[0063] (2) Add γ-glycidyl etheroxytrimethoxysilane to a water / ethanol mixed solvent with a volume ratio of 1:4 to form a 2wt% silane solution, adjust the pH to 3 with 0.1mol / L hydrochloric acid, and Magnetic stirring at 500 rpm at room temperature for 2 hours to carry out hydrolysis reaction to obtain a silanol solution....

Embodiment 3

[0068] (1) Stir and dissolve sodium carbonate in deionized water, add dibutyl phosphate according to the molar ratio of dibutyl phosphate to sodium is 1:1, to obtain a 0.1mol / L sodium organophosphate solution; configure 0.033mol / L chlorinated For cerium solution, add an equal volume of cerium chloride solution to the sodium organophosphate solution dropwise, stir rapidly at room temperature, continue stirring for 1 hour after the addition, wash with deionized water for 6 times, separate by suction filtration, and dry at 50°C for 30 hours to obtain Cerium organophosphate (Ce(dbp) 3 ) into a pulverizer to grind the solid to obtain restoration agent granules.

[0069] (2) Add γ-glycidyl etheroxytrimethoxysilane into a water / ethanol mixed solvent with a volume ratio of 4:5 to configure a 5wt% silane solution, adjust the pH to 4 with 0.1mol / L hydrochloric acid, and Magnetic stirring at 500 rpm at room temperature for 3 hours to carry out hydrolysis reaction to obtain a silanol sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com