Lithium ion battery pole piece surface treatment method and system

A lithium-ion battery and surface treatment technology, which is applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of high stability and reliability of treatment quality, high cost and low motion control speed, etc. , to achieve the effect of improving laser processing efficiency, low processing cost and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

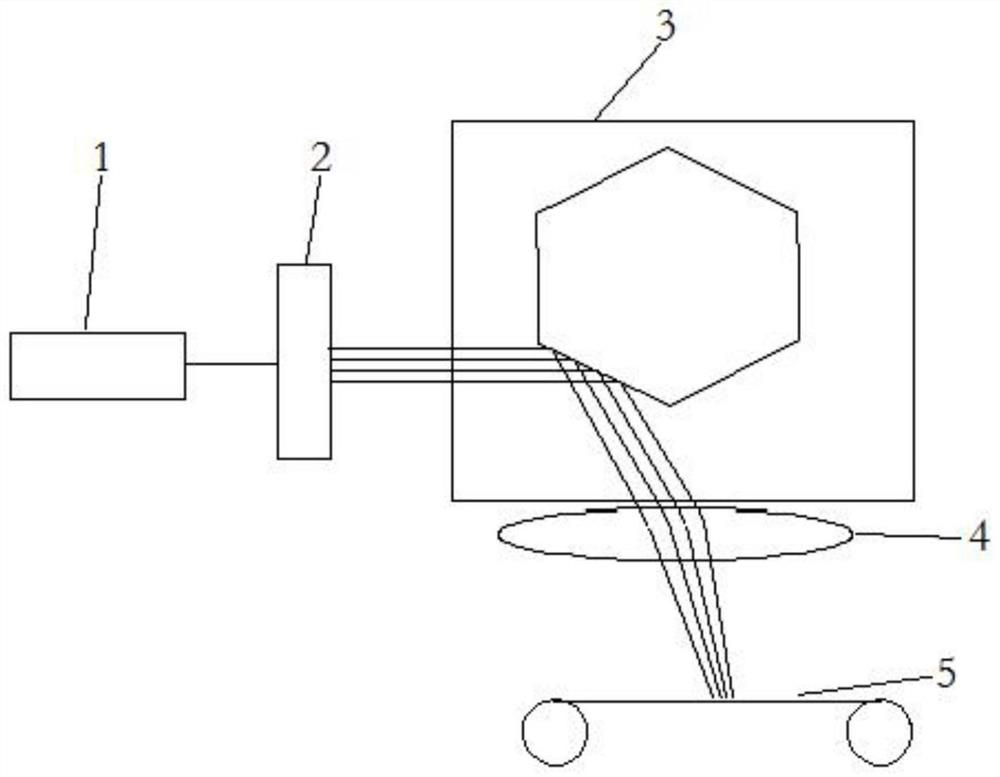

[0027] Such as figure 1 , the embodiment of the present invention provides a lithium-ion battery pole piece surface treatment method, comprising:

[0028] Hold the battery pole piece 5 by the clamp and make the surface of the battery pole piece 5 smooth;

[0029] The laser 1 emits laser light, splits the single laser beam into multiple laser beams, guides the multiple laser beams to the focusing lens 4 through the rotating mirror 3, and focuses the multiple laser beams on the battery pole pieces 5 respectively by the focusing lens 4 A plurality of holes or grooves are formed on the battery pole piece 5 .

[0030] Preferably, the above-mentioned clamp adopts a roller-type clamp. In one of the embodiments, a double roller structure is adopted, and the battery pole piece 5 is stretched flat by the tension of two sets of rollers, and the bottom of the pole piece is emptied; in another embodiment, a single roller structure is adopted, and the The battery pole piece 5 is coated o...

Embodiment 2

[0042] Such as figure 1 , an embodiment of the present invention provides a lithium-ion battery pole piece surface treatment system, including:

[0043] laser 1;

[0044] A jig for clamping the battery pole piece 5 and making the surface of the battery pole piece 5 smooth;

[0045] A beam splitter 2, a rotating mirror 3 and a focusing lens 4; the beam splitting mirror 2 is arranged on the laser output path of the laser 1, and is used to split a single laser beam into multiple laser beams; the rotating mirror 3 is arranged on the The focus lens 4 is arranged on the light output path of the rotating mirror 3 and can focus multiple laser beams onto the surface of the battery pole piece 5 respectively.

[0046] The relevant structure of the processing system has been mentioned in the first embodiment above, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com