Preparation method of low-defect silicon carbide epitaxial material

A technology of epitaxial materials and silicon carbide, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems that restrict device performance, achieve low surface defect density, uniform temperature field, and reduce inhomogeneity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to facilitate the understanding of those skilled in the art, the present invention will be further described in detail below in conjunction with specific embodiments.

[0022] Embodiments of the present invention firstly provide a method for preparing a low-defect silicon carbide epitaxial material.

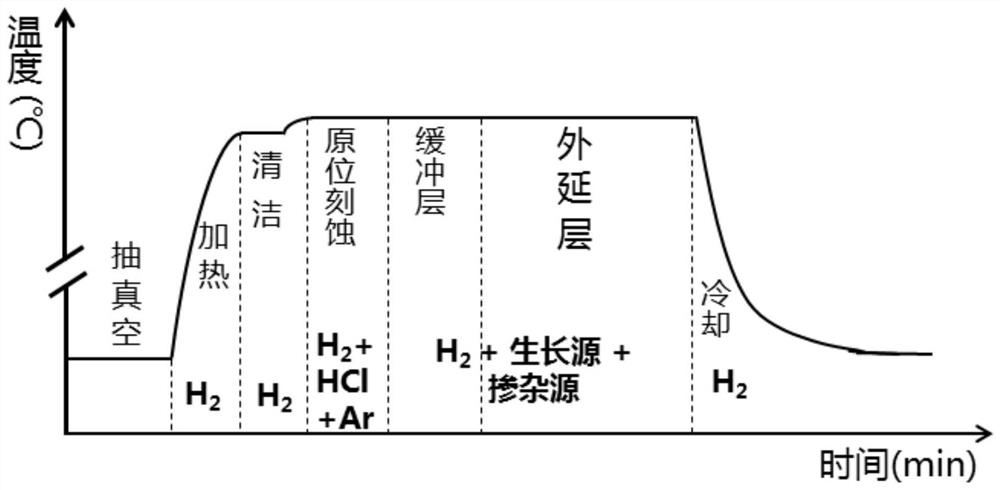

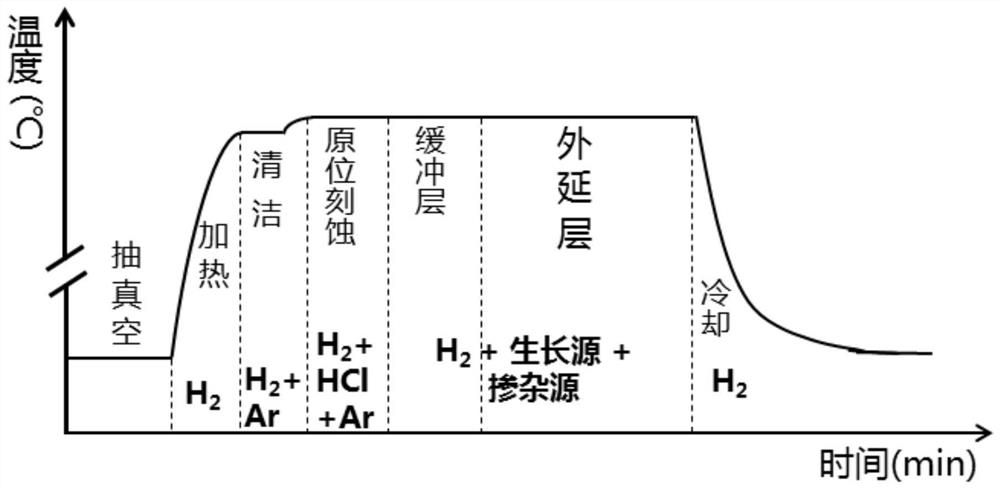

[0023] Please refer to figure 1 , is a schematic diagram of a method for preparing a low-defect silicon carbide epitaxial material provided by the first embodiment of the present invention.

[0024] The first stage is the preparatory work before preparation, which specifically includes: transferring the cleaned silicon carbide off-axis substrate to the graphite disk base in the CVD equipment, and the CVD equipment is vacuumed. In this embodiment, the silicon carbide off-axis substrate is a 4H-SiC or 6H-SiC substrate that is biased to the silicon surface of the direction by 0.2-8° (0001), and the CVD equipment adopts hot-wall CVD equipment, in other embodiments,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com