Plugging agent for drilling fluid and preparation method thereof

A plugging agent and drilling fluid technology, applied in the field of drilling fluid plugging agent and its preparation, can solve the problem of immature development and application of oil-based drilling fluid anti-leakage plugging technology, fast expansion rate and difficult to control, oil Improve the stability of the wellbore wall, improve the plugging effect, and improve the high temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

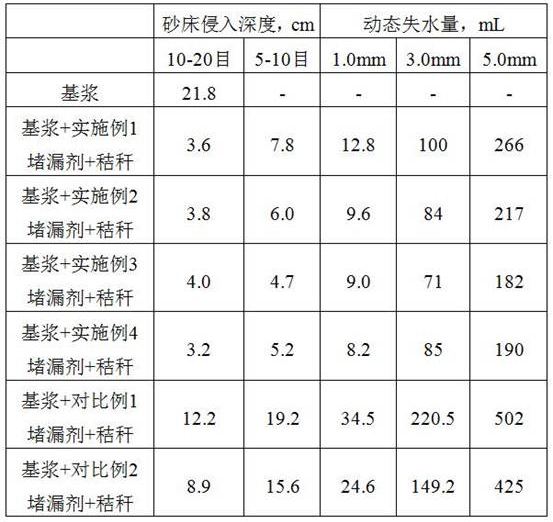

Examples

Embodiment 1

[0035] Heat 200g of blended asphalt with a softening point of 62.5°C to a molten state, add 18.2g of maleic anhydride, feed nitrogen to keep the pressure of the asphalt reactor at 0.8MPa, and react at 180°C for 6 hours to obtain grafted activated asphalt. Add 21.5 g of pozzolan with an average particle size of 250 nm (sulfur content: 6.4 wt%) to the grafted activated asphalt, and mix and react at 160°C for 50 minutes to obtain the modified asphalt.

[0036] Add 32.5g of 80-mesh nitrile rubber powder to the modified asphalt, and shear at 180°C for 35min. Freeze at -30°C for 5 hours. Then crush it with a pulverizer. Use 40-mesh, 80-mesh, 120-mesh and 160-mesh standard sieves to sieve to obtain highly elastic modified asphalt particles with different particle sizes of 40-80 mesh, 80-120 mesh, 120-160 mesh, and >160 mesh.

[0037] Take 90g of the above-mentioned highly elastic modified asphalt particles (including 30wt% of 40-80 mesh particles, 35wt% of 120-160 mesh particles, 3...

Embodiment 2

[0039] Heat 200g of oxidized asphalt with a softening point of 71.5°C to a molten state, add 12.5g of polyglutaric anhydride, feed nitrogen to keep the pressure of the asphalt reactor at 0.6MPa, and react at 190°C for 5 hours to obtain grafted activated asphalt. Add 16.2 g of pozzolan with an average particle size of 400 nm (sulfur content is 7.6 wt%) to the grafted activated asphalt, and mix and react at 165°C for 60 minutes to obtain the modified asphalt.

[0040] Add 42.5g of 100-mesh neoprene rubber powder to the modified asphalt, and shear at 175°C for 50min. Freeze at -35°C for 5 hours. Then crush it with a pulverizer. Use 40-mesh, 80-mesh, 120-mesh and 160-mesh standard sieves to sieve to obtain highly elastic modified asphalt particles with different particle sizes of 40-80 mesh, 80-120 mesh, 120-160 mesh, and >160 mesh.

[0041] Take 68g of the above-mentioned highly elastic modified asphalt particles (including 35wt% of 40-80 mesh particles, 50wt% of 80-120 mesh pa...

Embodiment 3

[0043] Heat 200g of oxidized asphalt with a softening point of 78.4°C to a molten state, add 31.2g of polyoxalic anhydride, feed nitrogen to keep the pressure of the asphalt reactor at 0.6MPa, and react at 195°C for 4.5 hours to obtain grafted activated asphalt. Add 24.6 g of pozzolan with an average particle size of 650 nm (with a sulfur content of 11.5 wt%) to the grafted activated asphalt, and mix and react at 170°C for 70 minutes to obtain the modified asphalt.

[0044] Add 51.5g of 120 mesh styrene-butadiene rubber powder to the modified asphalt, and shear at 170°C for 60min. Freeze at -45°C for 5.5 hours. Then crush it with a pulverizer. Use 40-mesh, 80-mesh, 120-mesh and 160-mesh standard sieves to sieve to obtain highly elastic modified asphalt particles with different particle sizes of 40-80 mesh, 80-120 mesh, 120-160 mesh, and >160 mesh.

[0045] Take 85g of the above-mentioned highly elastic modified asphalt particles (including 25wt% of 80-120 mesh particles, 50w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com