High-wear-resistance and high-sewage-resistance waterborne coating and preparation method thereof

A high wear-resisting and coating technology, applied in epoxy resin coatings, coatings, etc., to achieve the effects of low preparation cost, shortened production time and remarkable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

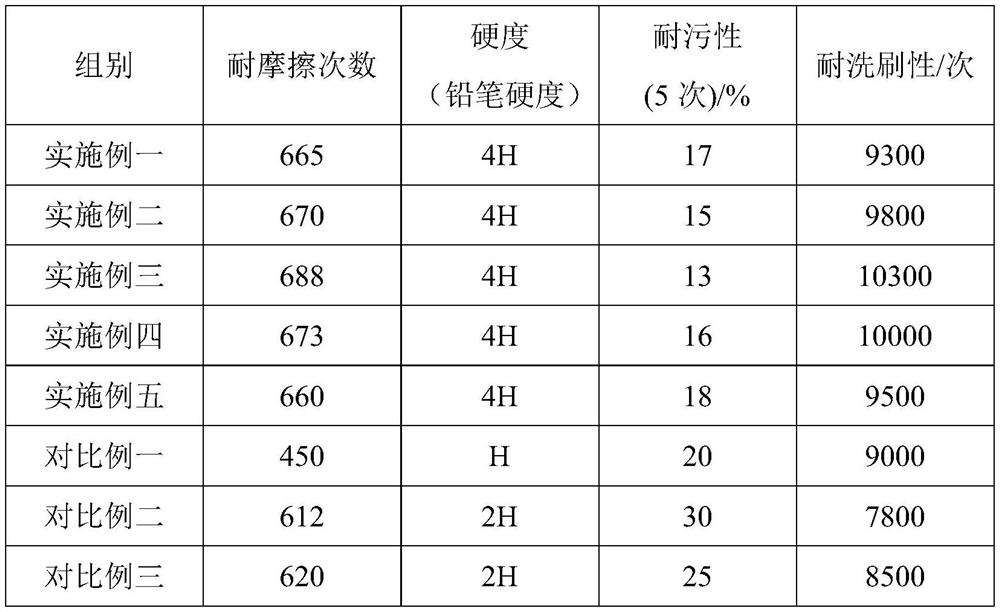

Examples

Embodiment 1

[0038] A kind of high wear-resisting high anti-pollution paint that the application proposes, comprises the raw material of following weight part: 50 parts of epoxy resins, 10 parts of inorganic fillers, 2 parts of silane coupling agents, 1 part of pigments, 0.1 parts of leveling agents, 0.2 parts of defoamer, 0.5 parts of curing agent, 8 parts of paint additives, 38 parts of water;

[0039] Wherein, inorganic filler is made by following method:

[0040] (1) According to the mass ratio of 5:1, mica and aramid fibers are mixed and pulverized to obtain a particle diameter of 80 mesh inorganic filler powders;

[0041] (2) According to the ratio of material to liquid 1:6, add a solvent to the inorganic filler powder and stir, add a silane coupling agent while stirring to modify the surface of the inorganic filler, control the temperature at 40 ° C during the operation, and obtain the inorganic filler Stock solution; the solvent is a mixed solution of triethylamine, ethyl acetate ...

Embodiment 2

[0054] A kind of high wear-resisting high anti-pollution paint that the application proposes, comprises the raw material of following weight part: 55 parts of epoxy resins, 12 parts of inorganic fillers, 3 parts of silane coupling agents, 1.2 parts of pigments, 0.2 parts of leveling agents, 0.4 parts of defoamer, 0.7 parts of curing agent, 9 parts of paint additives, 42 parts of water;

[0055] Wherein, inorganic filler is made by following method:

[0056] (1) According to the mass ratio of 10:3, mica and aramid fibers are mixed and pulverized to obtain a particle size of 90 mesh inorganic filler powders;

[0057] (2) According to the ratio of material to liquid 1:7, add a solvent to the inorganic filler powder and stir, add a silane coupling agent while stirring to modify the surface of the inorganic filler, control the temperature at 45°C during the operation, and obtain the inorganic filler Stock solution; the solvent is a mixed solution of triethylamine, ethyl acetate an...

Embodiment 3

[0070] A kind of high wear-resisting high anti-pollution paint that the application proposes, comprises the raw material of following weight part: 50 parts of epoxy resins, 13 parts of inorganic fillers, 4 parts of silane coupling agents, 1.5 parts of pigments, 0.4 parts of leveling agents, 0.6 parts of defoamer, 0.8 parts of curing agent, 10 parts of paint additives, 46 parts of water;

[0071] Wherein, inorganic filler is made by following method:

[0072] (1) According to the mass ratio of 13:2, mica and aramid fibers are mixed and pulverized to obtain a particle size of 100 mesh inorganic filler powders;

[0073] (2) According to the ratio of material to liquid 1:8, add a solvent to the inorganic filler powder and stir, add a silane coupling agent while stirring to modify the surface of the inorganic filler, control the temperature at 50°C during the operation, and obtain the inorganic filler Stock solution; the solvent is a mixed solution of triethylamine, ethyl acetate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com