Conductive bio-based plastic as well as preparation method and application thereof

A bio-based plastic and bio-based technology, applied in the direction of electrical components, magnetic field/electric field shielding, etc., can solve the problems of electromagnetic shielding energy-efficient fillers that are easy to agglomerate, difficult to shape, and cannot meet the requirements of use, and achieve excellent electromagnetic shielding performance, high The effect of conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Provide a conductive bio-based plastic: rGO / starch-based polyethylene, by mass percentage, its raw materials include:

[0046] Starch 10%;

[0047] Polyethylene 70%;

[0048] Hydrophobic association polyacrylamide modified rGO 20% (wherein the weight ratio of hydrophobic association polyacrylamide in the two-dimensional material is 50%).

[0049] Its preparation method comprises the following steps:

[0050]1) Install a thermometer, a reflux condenser and a mechanical stirrer on the three-necked flask, and feed nitrogen gas at the same time, add 15g of surfactant, 14g of acrylamide, 0.3g of N-dodecylacrylamide, and 450g of deionized water. After stirring for 15 hours, it was heated to 50°C, and potassium persulfate was added to react for 3 hours. Then cool down and add an appropriate amount of water and acetone to precipitate the polymer, and dry under reduced pressure for 24 hours to obtain the product hydrophobically associated polyacrylamide. Subsequently, the ob...

Embodiment 2

[0058] A conductive bio-based plastic titanium carbon / protein-based PS is provided, and its raw materials include:

[0059] Protein 10%;

[0060] PS 75%;

[0061] Hydrophobic association hydroxyethyl cellulose modified carbon titanide 15% (wherein the mass proportion of hydrophobic association hydroxyethyl cellulose is 30%).

[0062] Its preparation method comprises the following steps:

[0063] 1) Add the cellulose isopropanol solution (9%wt) into the three-necked flask, stir vigorously for 30min, slowly drop in 5%wt NaOH solution, stir at high speed, reduce the stirring speed after the dropwise addition, pass in nitrogen, and keep at room temperature Let stand for 24h. Heating to 80°C, adding hydrophobic monomer, and reacting for 8h. After cooling with cold water, the initial product was washed with n-hexane and soaked overnight. Then wash with 80% acetone until neutral, and then wash with 90% and 100% acetone for 2 hours respectively. The product was vacuum-dried for ...

Embodiment 3

[0071] Provide a conductive bio-based plastic: montmorillonite / animal gum-based PVC, in terms of mass percentage, its raw materials include:

[0072] Animal glue 20%;

[0073] PVC 62%;

[0074] 18% of montmorillonite modified by hydrophobic association polyacrylamide (the mass proportion of hydrophobic association polyacrylamide is 50%).

[0075] Its preparation method comprises the following steps:

[0076] 1) Install a thermometer, a reflux condenser and a mechanical stirrer on the three-necked flask, and feed nitrogen gas at the same time, add 15g of surfactant, 14g of acrylamide, 0.3g of N-dodecylacrylamide, and 450g of deionized water. After stirring for 15 hours, it was heated to 50°C, and potassium persulfate was added to react for 3 hours. Then cool down and add appropriate amount of water and acetone to precipitate the polymer, and dry under reduced pressure for 24 hours to obtain the product hydrophobically associated acrylamide. Subsequently, the obtained hydrop...

PUM

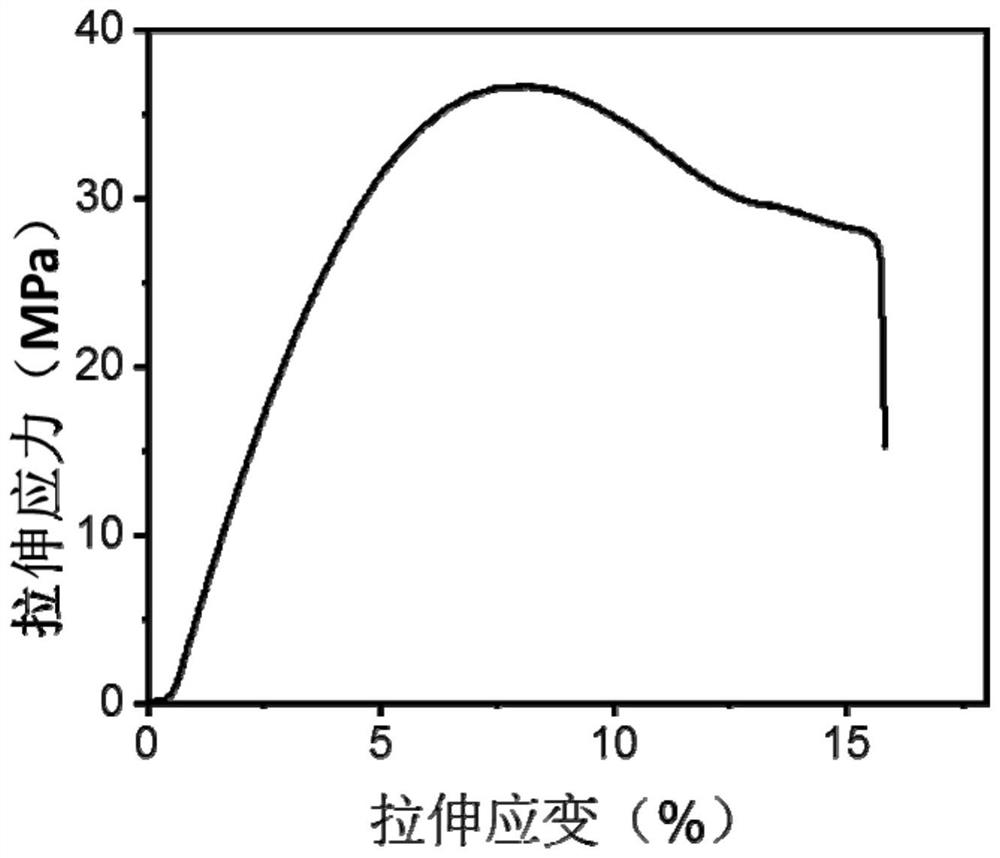

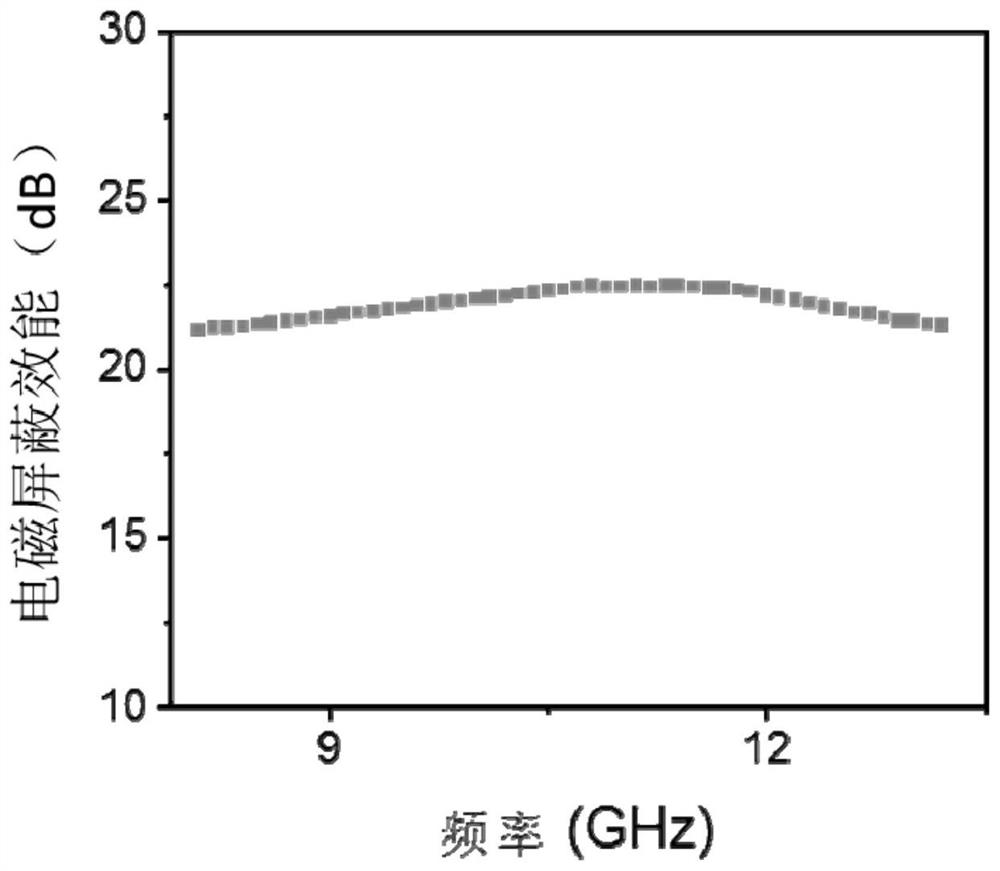

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Electromagnetic shielding effectiveness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com