Polycarboxylate superplasticizer capable of effectively resisting influence of flocculating agent and preparation method of polycarboxylate superplasticizer

A technology of flocculant and polycarboxylic acid, which is applied in the field of water reducing agent, can solve the problems of concrete slump loss, low concrete strength, and reduce concrete fluidity, so as to achieve low viscosity, facilitate pumping, and improve wrapping property entanglement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

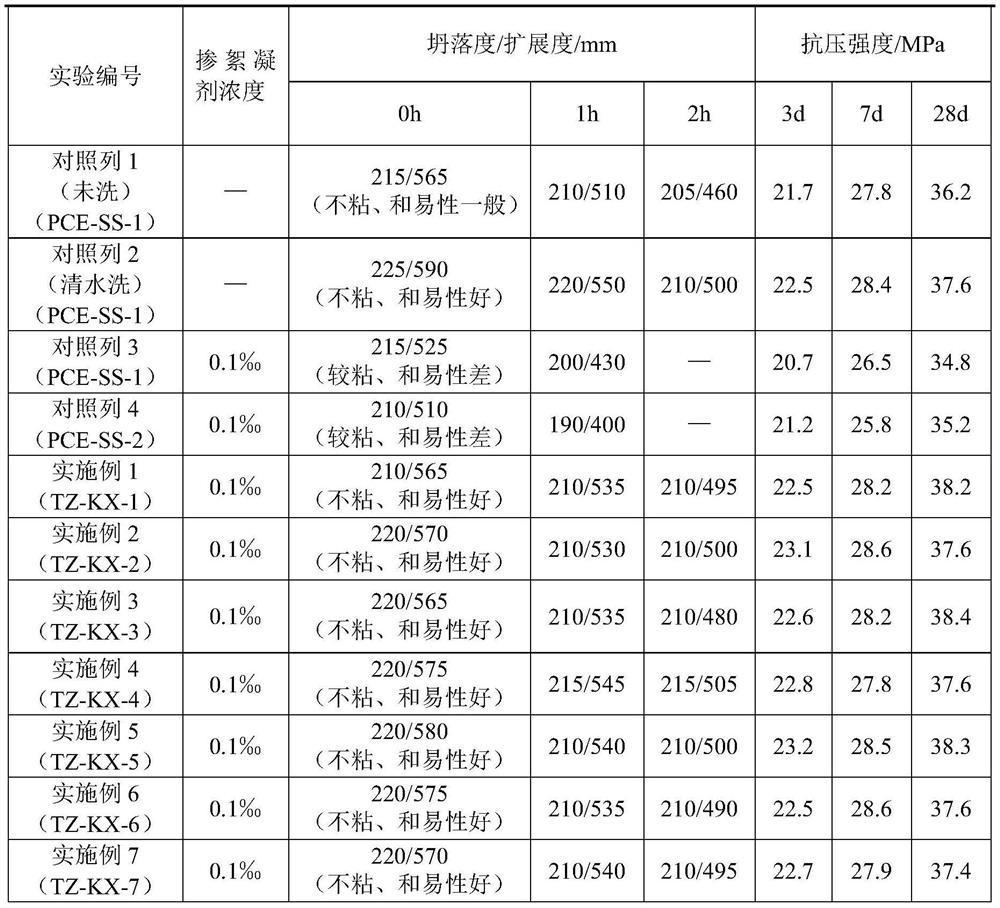

Examples

Embodiment 1

[0030] A kind of polycarboxylate water reducing agent that effectively resists the influence of flocculant, its preparation method comprises the following steps:

[0031] (1) Add 335 parts of diethylene glycol monovinyl polyoxyethylene ether macromonomer, 3.2 parts of 32% sodium hydroxide solution and 280 parts of deionized water into the reaction kettle, stir until it dissolves until there is no obvious lump solution in shape or sheet;

[0032] (2) Measure the temperature in the reactor, control the initial temperature to 21° C., and throw in 3.4 parts of hydrogen peroxide and 0.009 part of rhodium (II) acetate dimer at one time;

[0033] (3) After 5 minutes, start to drop the solution A consisting of 0.7 parts of 2-hydroxy-2-sulfinic acid-disodium salt, 1.6 parts of 2-mercaptoethanol and 136 parts of deionized water, and the dropping time is 1.25 hours ;

[0034] (4) After another 2 minutes, start to drop the mixture prepared by adding 16 parts of acrylic acid, 32 parts of...

Embodiment 2

[0037] A kind of polycarboxylate water reducing agent that effectively resists the influence of flocculant, its preparation method comprises the following steps:

[0038] (1) Add 340 parts of diethylene glycol monovinyl polyoxyethylene ether macromonomer, 3.4 parts of 28% ammonia water and 290 parts of deionized water into the reaction kettle, stir until it dissolves until there are no obvious lumps or flakes solution;

[0039] (2) Measure the temperature in the reactor, control the initial temperature to 22°C, and throw in 3.6 parts of tert-butyl hydroperoxide and 0.006 parts of palladium acetate at one time;

[0040] (3) After 5 minutes, start dropwise adding solution A consisting of 0.9 parts of 2-hydroxyphenyl hydroxymethylsulfinic acid-sodium salt, 1.8 parts of 3-mercaptopropionic acid isooctyl ester and 142 parts of deionized water. 1.2h;

[0041] (4) After another 1min, start to add 16.6 parts of acrylic acid, 34 parts of methacryloxyethylpyrrolidone, 5.8 parts of tet...

Embodiment 3

[0044] A kind of polycarboxylate water reducing agent that effectively resists the influence of flocculant, its preparation method comprises the following steps:

[0045] (1) Add 350 parts of 4-hydroxybutyl vinyl ether polyoxyethylene ether macromonomer, 3.6 parts of 32% sodium hydroxide solution and 300 parts of deionized water into the reaction kettle, stir until it dissolves until there is no obvious lump solution in shape or sheet;

[0046] (2) Measure the temperature in the reactor, control the initial temperature to 16°C, and throw in 3.2 parts of tert-butyl hydroperoxide and 0.008 parts of ruthenium acetate at one time;

[0047] (3) After 5 minutes, start dropwise adding solution A consisting of 0.82 parts of 2-hydroxy-2-sulfinic acid-zinc salt, 1.5 parts of 3-mercaptopropionic acid and 145 parts of deionized water, and the dropping time is 1.2 hours ;

[0048] (4) After another 2 minutes, start to add 13.6 parts of methacrylic acid, 4.2 parts of crotonic acid, 33.6 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com