Preparation method, product and application of lead-free halogen microcrystal

A micro-crystal and lead-halogen technology, which is applied in the field of preparation of lead-free halogen micro-crystal, can solve the problems affecting the application value and poor stability of cesium-lead-bromine scintillator materials, and achieve easy operation, good thermal stability and light stability Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Preparation of a Rb 2 AgCl 3 Lead-free halogen microcrystals, the specific preparation method is as follows:

[0035] (1) Mix and dissolve 0.1mmol (14.3mg) AgCl and 0.2mmol (24.2mg) RbCl in 2mL dimethyl sulfoxide, place on a heating platform at 60°C and heat for 4h until the solution is completely clear to obtain a precursor solution;

[0036] (2) After the solution is completely clarified, use isopropanol as the anti-solvent, and perform anti-solvent extraction according to the standard that 200 μL of the precursor solution is dissolved and dispersed into 4 mL of isopropanol;

[0037] (3) After the extraction, centrifuge at 9000rps for 5 minutes to obtain a precipitate, put it in a drying oven and dry it to get Rb 2 AgCl 3 Lead-free halogen microcrystalline.

Embodiment 2

[0039] Preparation of a Rb 2 AgCl 3 Lead-free halogen microcrystals, the specific preparation method is as follows:

[0040] (1) Mix and dissolve 14.1mg AgCl and 24.2mg RbCl in 2mL dimethyl sulfoxide, place on a heating platform at 60°C and heat for 5h until the solution is completely clear to obtain a precursor solution;

[0041](2) After the solution is completely clarified, use isopropanol as the anti-solvent, and perform anti-solvent extraction according to the standard that 200 μL of the precursor solution is dissolved and dispersed into 4 mL of isopropanol;

[0042] (3) After extraction, centrifuge at 9000rps for 5 minutes to obtain a precipitate, put it in a drying oven to dry to obtain Rb 2 AgCl 3 Lead-free halogen microcrystalline.

Embodiment 3

[0044] With the Rb prepared in embodiment 2 2 AgCl 3 Lead-free halogen microcrystals for the preparation of Rb 2 AgCl 3 Lead-free halogen microcrystalline thin film, the specific preparation method is as follows:

[0045] (1) Rb 2 AgCl 3 Pour the lead-free halogen micro-crystals into the mortar and grind until there are no large particles;

[0046] (2) Pour the glue into the mortar according to the volume-to-mass ratio of 1:20, mL:mg, Rb 2 AgCl 3 The lead-free halogen microcrystalline powder and glue are mixed and ground until the glue and powder are evenly distributed together, and there are no large particles, and the fine powder is evenly distributed in the glue;

[0047] (3) the mixed Rb 2 AgCl 3 - Spread the glue evenly, put it in a 100°C oven for 1-3 hours to cure.

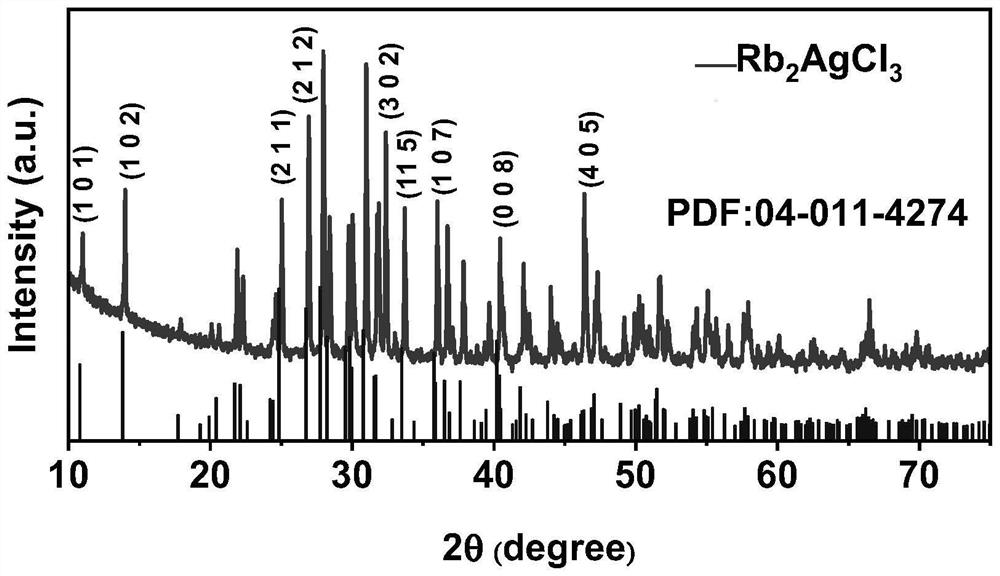

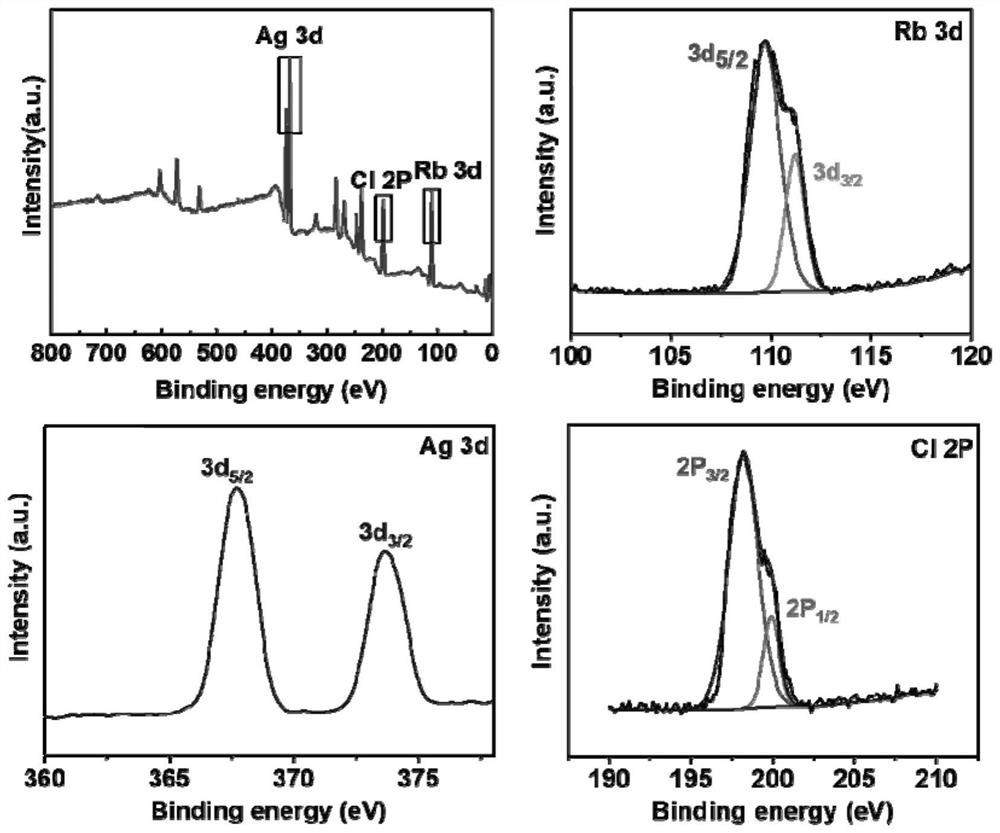

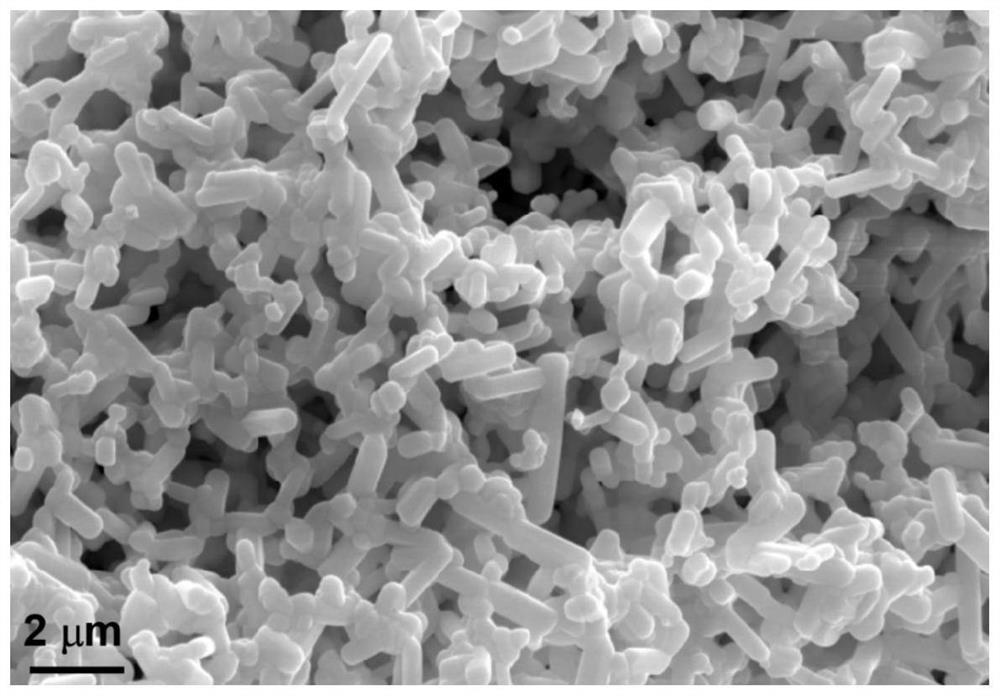

[0048] figure 1 For the Rb prepared in Example 1 2 AgCl 3 The X-ray diffraction pattern of lead-free halogen microcrystals, the diffraction peaks are consistent with the standard XRD card; fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com