Modification method of silicon molecular sieve and preparation method of caprolactam

A silicon molecular sieve and caprolactam technology, applied in the field of caprolactam preparation, can solve problems such as short lifespan, and achieve the effects of increasing operating life, improving selectivity and lifespan, and increasing external specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] In another typical embodiment of the present application, a preparation method of caprolactam is provided, the preparation method comprising: Step A, gasifying cyclohexanone oxime to obtain a gasified product; Step B, using a catalyst to catalyze the gas The chemical compound is subjected to a gas-phase Beckmann rearrangement reaction to obtain a product system containing caprolactam, and the catalyst is a modified silicon molecular sieve obtained by any of the above-mentioned modification methods; Step C is to purify the caprolactam in the product system to obtain caprolactam.

[0029]The caprolactam selectivity and cyclohexanone oxime conversion rate of the modified silicon molecular sieve modified by the modification method of the present application are maintained at a high level, and the service life of the catalyst is significantly prolonged, which improves the production efficiency of caprolactam.

[0030] The gasification process of cyclohexanone oxime, the gas p...

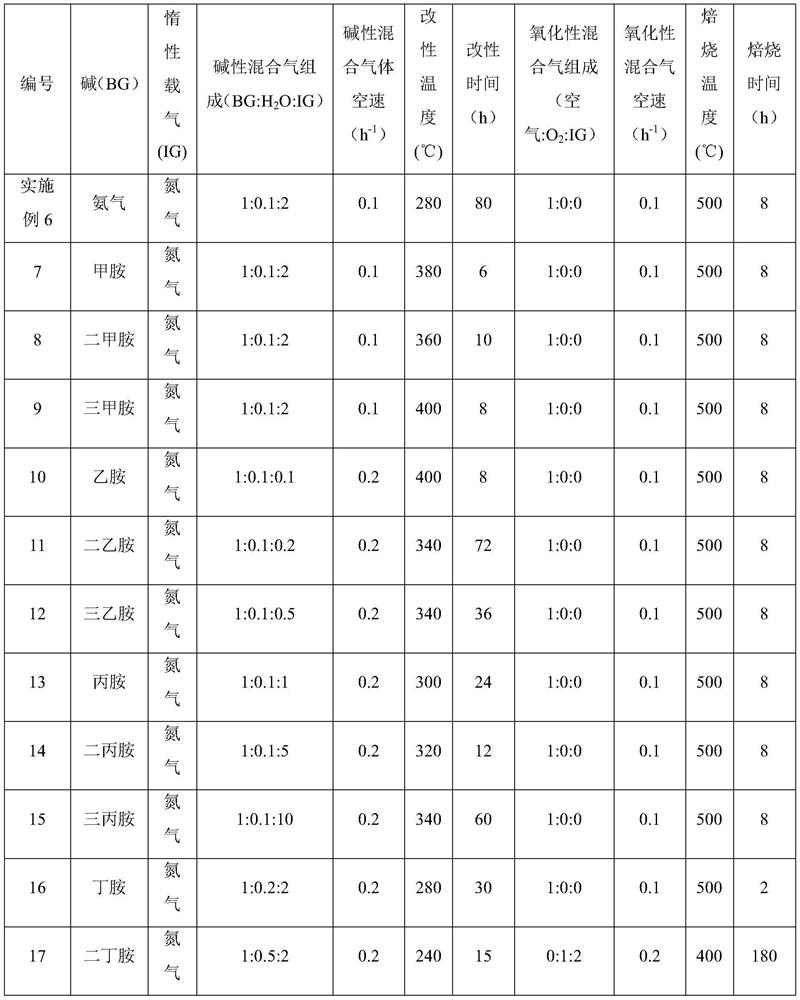

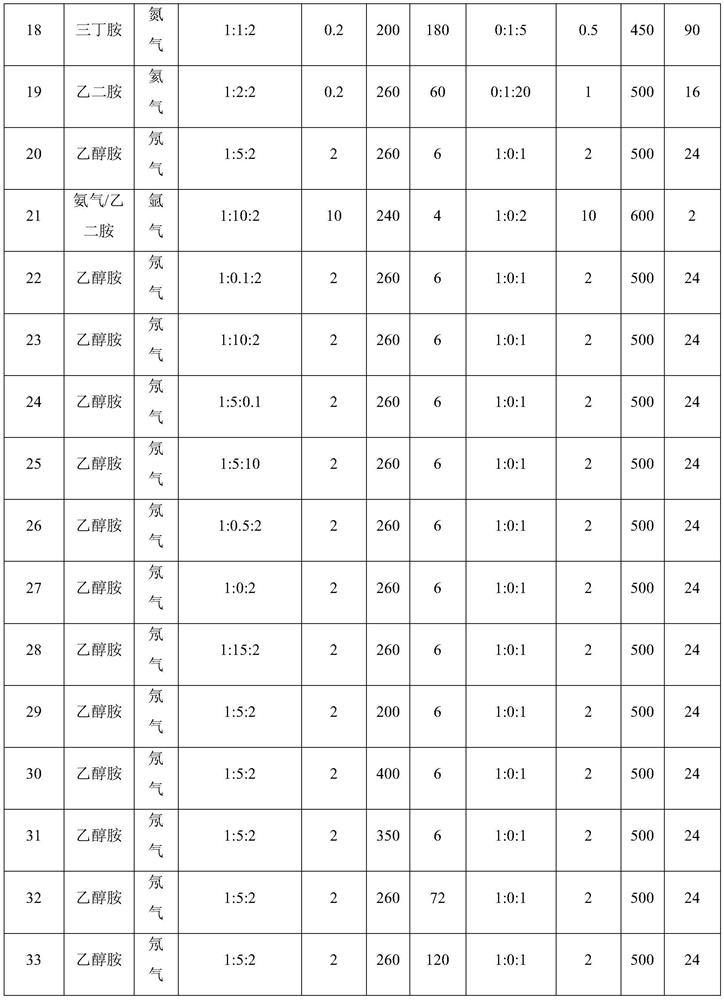

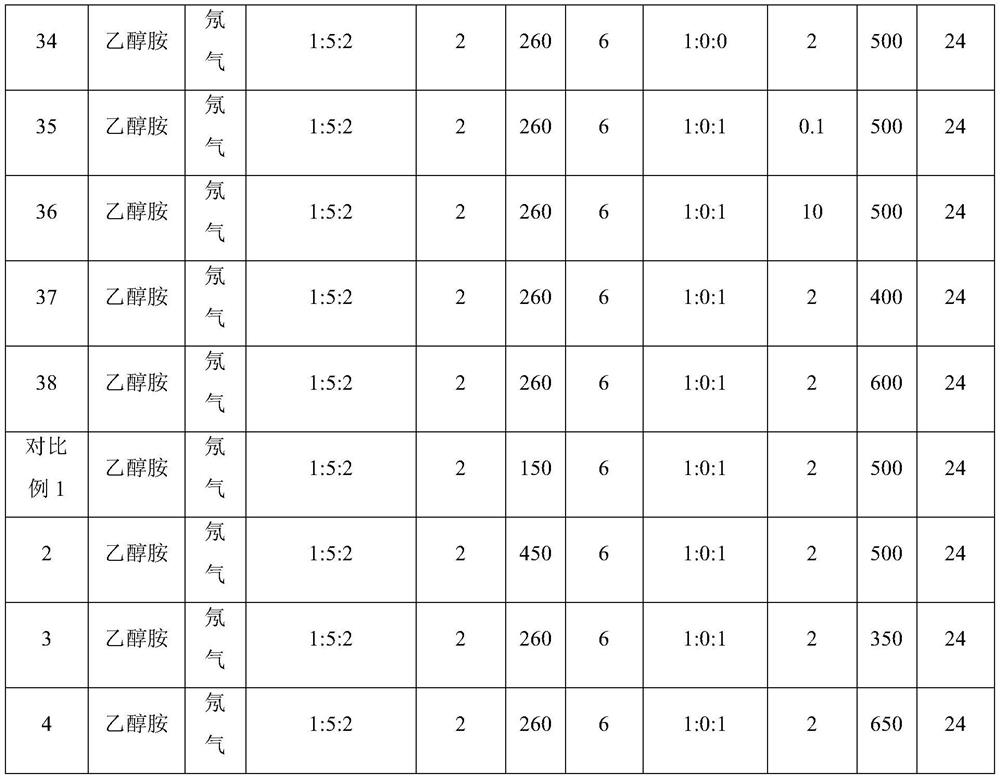

Embodiment 1

[0034] 30g of all-silicon molecular sieve powder Silicalite-1 (average pore diameter 14.3nm, pore volume 0.8cm 3 / g, the specific surface area is 350m 2 / g) into a tube furnace, at 310°C for 0.5h -1 A mixture of ammonia, water vapor and nitrogen is introduced at a volumetric space velocity, wherein the volume ratio of ammonia: water vapor: nitrogen is 1:0.5:2, and the reaction takes 10 hours. Then, pass through to 2h -1 The volume space velocity is passed through nitrogen for 30min, and then switched to 0.5h at 500°C -1 The modified all-silicon molecular sieve was obtained by roasting in air for 10 hours.

Embodiment 2-5

[0036] On the basis of Example 1, silicon molecular sieves were changed, and the original powder Silicalite-1 (average pore diameter 0.1nm, pore volume 0.1cm) was crystallized with all-silicon molecular sieves respectively. 3 / g, the specific surface area is 272m 2 / g), spherical all-silicon molecular sieve Silicalite-1 (average pore diameter 27.5nm, pore volume 0.9cm 3 / g, the specific surface area is 375m 2 / g, ball diameter 0.2mm), cylindrical molecular sieve Silicalite-1 (average pore diameter 49.7nm, pore volume 4.8cm 3 / g, the specific surface area is 402m 2 / g, diameter 1.6mm, length 1.5mm) and circular Silicalite-1 (average pore diameter 36.3nm, pore volume 2.4cm 3 / g, the specific surface area is 251m 2 / g, internal diameter 1.1mm, external diameter 2.3mm, long 2.0mm) replace the former powder of all-silicon molecular sieve, modification method is the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com