Wear-resistant sports kneecap and processing technology thereof

A processing technology and knee pad technology, which is applied in the field of wear-resistant sports knee pads and its processing technology, can solve the problems that it is difficult to ensure wear resistance, antibacterial properties, and single advantages.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

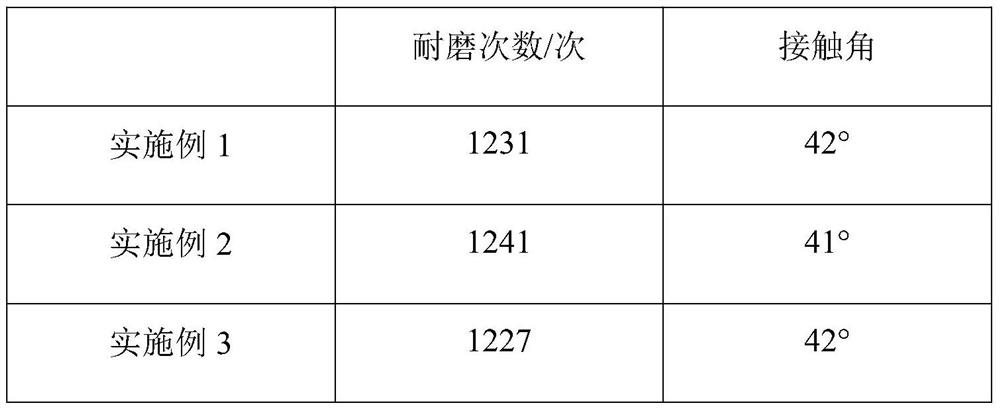

Examples

Embodiment 1

[0025] Step 1: Take N-N dimethylformamide solution, titanium boride particles, KH570, ultrasonically treat for 1.5h, add graphene oxide, ultrasonically treat for 35min, add silicone resin solution, stir at 143°C for 1.5h, add methyl Tetrahydroanhydride, sonicated for 35min, and dried to obtain solution A.

[0026] Solution A includes the following ingredients, by weight, 6 parts of titanium boride particles, 2 parts of KH570, 55 parts of N-N dimethylformamide solution, 4 parts of graphene oxide, 80 parts of silicone resin solution, 6 parts of methyl tetrahydro anhydride.

[0027] Step 2: Perform low-temperature plasma treatment on the polyester fabric. The output power of low-temperature plasma treatment is 250w, and the treatment time is 140s. Dry at ℃ for 6.5 hours to obtain the modified fabric.

[0028] Step 3: Add 8.3g of potassium ethyl xanthate and 8.0g of 2-bromopropionic acid into 30mL of ethanol, stir and react at 27°C for 22h, filter with suction, spin evaporate th...

Embodiment 2

[0036] Step 1: Take N-N dimethylformamide solution, titanium boride particles, KH570, sonicate for 1h, add graphene oxide, sonicate for 30min, add silicone resin solution, stir at 140°C for 1h, add methyltetrahydrogen acid anhydride, sonicated for 30 min, and dried to obtain solution A.

[0037] Solution A includes the following ingredients, by weight, 4 parts of titanium boride particles, 1 part of KH570, 40 parts of N-N dimethylformamide solution, 3 parts of graphene oxide, 70 parts of silicone resin solution, 5 parts of methyl tetrahydro anhydride.

[0038] Step 2: Perform low-temperature plasma treatment on the polyester fabric. The output power of the low-temperature plasma treatment is 200w, and the treatment time is 120s. After obtaining the low-temperature treated fabric, apply solution A to the low-temperature treated fabric by coating. Dry at ℃ for 6 hours to obtain the modified fabric.

[0039]Step 3: Add 8.3g of potassium ethyl xanthate and 8.0g of 2-bromopropion...

Embodiment 3

[0047] Step 1: Take N-N dimethylformamide solution, titanium boride particles, KH570, ultrasonic treatment for 2 hours, add graphene oxide, ultrasonic treatment for 40 minutes, add silicone resin solution, stir at 140-146 ° C for 2 hours, add methyl Tetrahydroanhydride, sonicated for 40 min, and dried to obtain solution A.

[0048] Solution A includes the following components, by weight, 8 parts of titanium boride particles, 3 parts of KH570, 70 parts of N-N dimethylformamide solution, 6 parts of graphene oxide, 90 parts of silicone resin solution, 7 parts of methyl tetrahydro anhydride.

[0049] Step 2: Perform low-temperature plasma treatment on the polyester fabric. The output power of the low-temperature plasma treatment is 300w, and the treatment time is 160s. After obtaining the low-temperature treated fabric, apply solution A to the low-temperature treated fabric by coating. Dry at ℃ for 7 hours to obtain the modified fabric.

[0050] Step 3: Add 8.3g of potassium eth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com