Compound weeding pesticide and preparation method thereof

A technology of pesticide and glufosinate-ammonium, which is applied in the field of compound herbicide pesticide and its preparation, can solve the problems of increased pesticide production cost, complicated pesticide formula, and limited synergistic effect, so as to improve the effect of weed control and excellent control effect. , to slow down the effects of drug resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

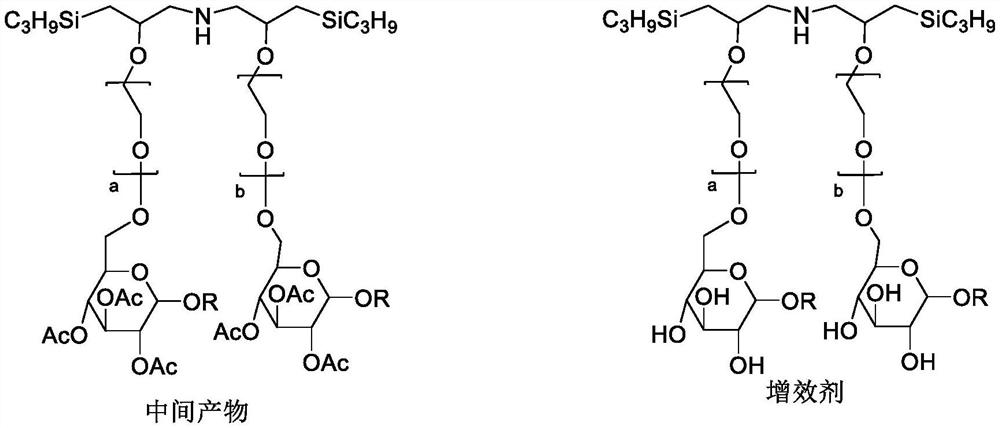

[0041] Polyoxyethylene ether modified organonitrogen silicon compound is prepared by the following steps:

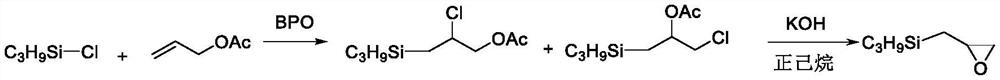

[0042] A. Add 0.1mol trimethylchlorosilane and 0.1mol anhydrous allyl acetate into a four-necked flask equipped with a condenser tube, a thermometer, a drying tube, and a stirring device, stir evenly, and then add them in four batches at room temperature 0.2g benzoyl peroxide, after the reaction temperature is stable, continue to stir for 30min, then add 100mL of anhydrous n-hexane and 0.2g potassium hydroxide, stir for 6h, stop the reaction, filter, and wash the filtrate with n-hexane to obtain epoxy Group-terminated siloxane;

[0043] B. Add 0.1mol epoxy-terminated siloxane, 20mL anhydrous methanol and 80mL ammonia water with a mass fraction of 25% into a sealed reaction vessel, stir at room temperature for 12h, and rotate at 30°C until the overflowing gas is neutral. Then add 0.1 mol of epoxy-terminated siloxane and 2 mL of methanol again, continue to stir the reacti...

Embodiment 2

[0046] Polyoxyethylene ether modified organonitrogen silicon compound is prepared by the following steps:

[0047] A. Add 0.1mol trimethylchlorosilane and 0.13mol anhydrous allyl acetate into a four-necked flask equipped with a condenser tube, a thermometer, a drying tube, and a stirring device, stir evenly, and then add them in four batches at room temperature 0.43g benzoyl peroxide, after the reaction temperature is stable, continue stirring for 30min, then add 200mL of anhydrous n-hexane and 0.54g potassium hydroxide, stir for 6h, stop the reaction, filter, and wash the filtrate with n-hexane to obtain epoxy Group-terminated siloxane;

[0048] B. Add 0.1mol epoxy-terminated siloxane, 40mL anhydrous methanol and 150mL ammonia water with a mass fraction of 25% into a sealed reaction vessel, stir at room temperature for 12 hours, and rotate at 30°C until the overflowing gas is neutral. Then add 0.1 mol of epoxy-terminated siloxane and 4 mL of methanol again, continue to stir ...

Embodiment 3

[0051] Synergists are made through the following steps:

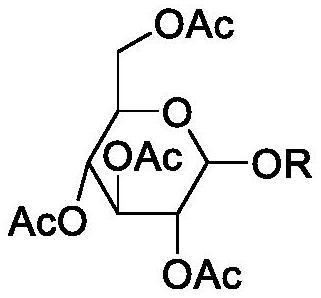

[0052] The first step, grind and mix 24g of alkyl glucoside and 4g of anhydrous sodium acetate in a mortar, transfer to a three-neck flask, add 0.45mol of acetic anhydride, heat and reflux for 2h, pour the product into ice water at 0°C and stir to solidify , the solid was recrystallized twice with ethanol, and dried in vacuum to obtain acetylated alkyl glycosides. The alkyl glycosides were alkyl glycosides APG1214, which were purchased from Hubei Coward Chemical Co., Ltd.; and the alkyl glycosides were degreased and dehydrated after purchase. The specific operation is to put the alkyl glucoside and diethylene glycol dimethyl ether into the reaction bottle, stir for 30 minutes, heat up, vacuumize, and distill under reduced pressure to remove the residual fatty alcohol and part of the solvent in the alkyl glycoside to obtain the pretreated Alkyl glycoside; then add the pretreated alkyl glycoside to the reaction kettle, va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com