Soilless spray-seeding substrate for mine greening and preparation method of soilless spray-seeding substrate

A mining and matrix technology, applied in the field of soilless matrix preparation, can solve the problems of synthesis source pollution, affecting vegetation growth and survival, slow release of formaldehyde molecules, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

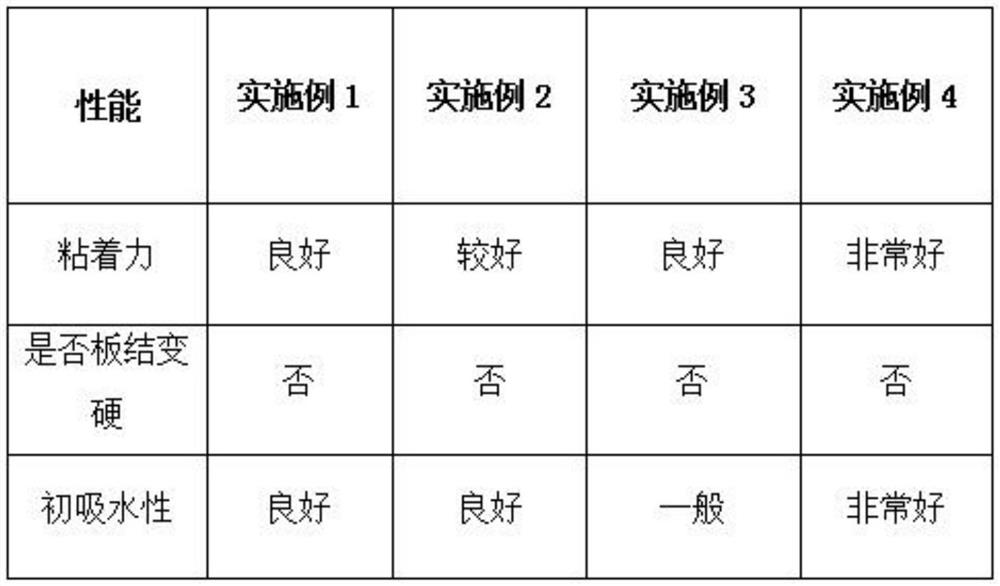

Examples

Embodiment 1

[0030] First, prepare the base material for spraying: add 40 parts of vermiculite powder, 60 parts of perlite, 105 parts of Northeast black charcoal soil and 615 parts of plant fiber into a horizontal mixer and stir for 30-300 minutes to obtain a well-mixed spraying base material. The fineness of the vermiculite powder is between 60-80 mesh. The diameter of the perlite particles is between 3-5 mm. The length of the plant fiber is between 1-10 mm, and the aspect ratio is between 4-20.

[0031] Then, prepare the binder solution: dissolving 6 parts of urea into 1000 parts of tap water, stirring and reacting at 10-100° C. for 10-50 minutes to promote the complete dissolution of urea. Then add 100 parts of cottonseed meal, and continue to stir and react for 10-240 minutes under the condition of 10-100°C. Then add 7 parts of citric acid, and continue to stir the reaction at 10-100° C. for 10-400 minutes.

[0032] After that, configure the water-retaining agent solution: take 35 ...

Embodiment 2

[0035] First, prepare the base material for spraying: add 60 parts of vermiculite powder, 80 parts of perlite, 120 parts of Northeast carbon soil and 700 parts of plant fiber into a horizontal mixer and stir for 30-300 minutes to obtain a well-mixed spraying base material. The fineness of the vermiculite powder is between 60-80 mesh. The diameter of the perlite particles is between 3-5 mm. The length of the plant fiber is between 1-10 mm, and the aspect ratio is between 4-20.

[0036] Then, prepare the binder solution: dissolving 13 parts of urea into 2000 parts of tap water, stirring and reacting at 10-100° C. for 10-50 minutes to promote the complete dissolution of urea. Then add 210 parts of cottonseed meal, and continue to stir and react for 30-200 minutes under the condition of 10-100°C. Then add 15 parts of citric acid, and continue to stir and react for 60-400 minutes under the condition of 10-100°C.

[0037] After that, configure the water-retaining agent solution:...

Embodiment 3

[0040] First, prepare the base material for spraying: add 85 parts of vermiculite powder, 125 parts of perlite, 150 parts of Northeast black charcoal soil and 820 parts of plant fiber into a horizontal mixer and stir for 30-300 minutes to obtain a well-mixed spraying base material. The fineness of the vermiculite powder is between 60-80 mesh. The diameter of the perlite particles is between 3-5 mm. The length of the plant fiber is between 1-10 mm, and the aspect ratio is between 4-20.

[0041] Then, prepare the binder solution: dissolving 30 parts of urea into 6000 parts of tap water, stirring and reacting at 10-100° C. for 10-50 minutes to promote the complete dissolution of urea. Then add 290 parts of cottonseed meal, and continue to stir and react for 30-200 minutes under the condition of 10-100°C. Then add 31 parts of citric acid, and continue to stir and react for 60-400 minutes at 10-100°C.

[0042] After that, configure the water-retaining agent solution: take 120 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com