Multi-scale seam net experimental device and experimental method thereof

An experimental device and multi-scale technology, applied in the direction of teaching models, instruments, educational tools, etc., can solve the problems of distribution on the surface of the core, large experimental errors, difficult to control, etc., and achieve the real effect of the intergranular contact state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

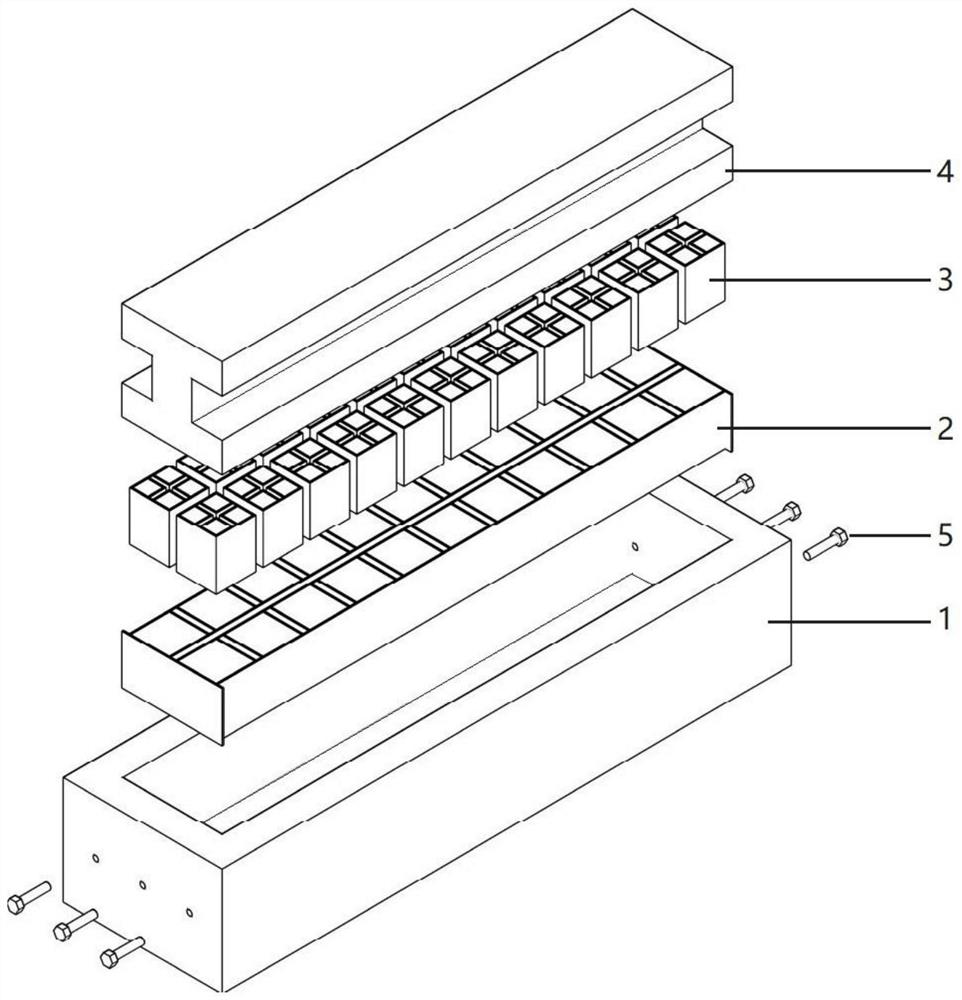

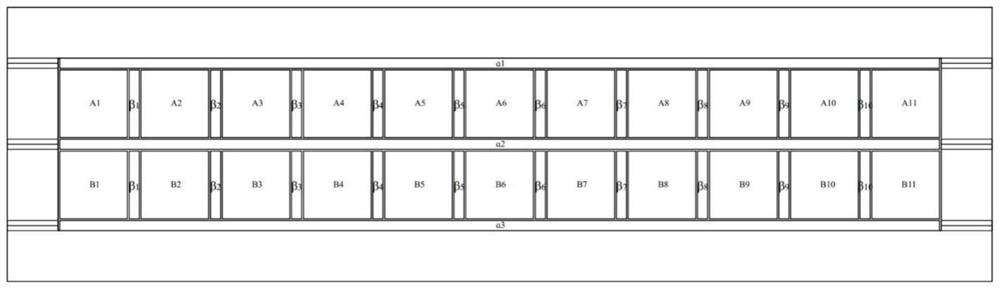

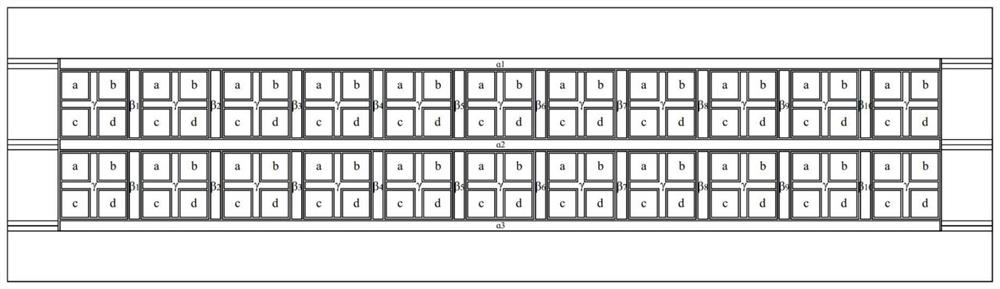

[0046] refer to figure 1 , figure 2 , image 3 , this embodiment provides a multi-scale fracture network experimental device and method based on a large data body, the experimental device includes a model main body frame 1, a digital partition board 2, a digital grid 3, a mold compact 4 and a displacement injection-production plug 5; the digital partition board 2 divides the model main body frame 1 into 22 mother areas of A1~A11, B1~B11, 3 longitude areas of α1~α3, and 10 latitude areas of β1~β10, of which the mother area It is used to install digital grids to simulate core matrix and micro-fractures, to simulate horizontal sections of horizontal wells in the warp zone, and to simulate natural fractures or hydraulic fractures in the latitudinal zone; the digital grids can be freely combined and embedded into A1~A11, B1~B11 have different parent areas, and the embedded parent area is divided into four sub-areas a, b, c, and d and a γ-network area, in which the sub-area is us...

Embodiment 2

[0048] image 3 It is a schematic diagram of the complete installation of the digital grid. Based on the digital partition board, the main frame of the model is divided into 22 mother areas of A1~A11 and B1~B11, 3 longitude areas of α1~α3, and 10 latitude areas of β1~β10. Grid 3 can divide up to 22 parent areas into 88 sub-areas and 22 network areas. With the help of logging curves and coring data, digital core parameter cloud maps can be made, and different sub-areas corresponding to the model based on the reservoir can be clearly defined. matrix porosity and permeability, and then use pre-prepared natural cores or artificial cores with different physical properties to fill sub-areas and longitude, latitude, and network areas without crack distribution, and use different particle sizes of ceramsite to fill the sub-areas with crack distribution. The warp zone, latitude zone, and grid zone are filled, and cast together with the main body frame of the model after being pressed a...

Embodiment 3

[0050] image 3 It is a schematic diagram of the complete installation of the digital grid. Based on 3 longitude zones, 10 latitude zones and at most 88 sub-zones and 22 grid zones, natural cores or artificial cores with different physical properties are filled in the sub-zones respectively. The ceramsite of different particle sizes is filled in the network area, and then cast together with the main body frame of the model after pressing and forming, which can realize the simulation of fractured core, in which the matrix is simulated in the sub-area, the hydraulic fracture is simulated in the warp area, and the cluster of fractures in the latitude area is simulated. Natural cracks and network areas simulate micro-cracks.

[0051] Further, refer to Figure 4 Schematic diagram of digital grid staggered installation, using the staggered combination arrangement of longitude zone, latitude zone and grid zone, which can realize the simulation of fully and insufficiently developed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com