High-definition color-enhanced anti-blue-ray lens and processing method thereof

An anti-blue light and lens technology, which is applied in the field of lenses, can solve the problems of lack of beneficial blue light and insufficient protective performance of harmful blue light, and achieve the effect of increasing depth perception, anti-ultraviolet color and contrast enhancement effect, excellent color and contrast enhancement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

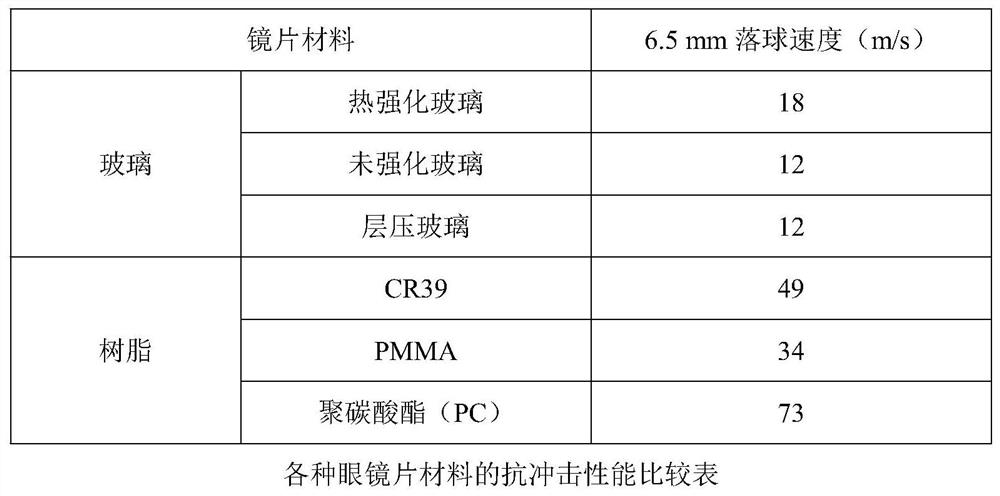

[0048] A high-definition color enhancement and anti-blue light lens, comprising: a resin substrate and a silicone resin film layer arranged on the surface thereof; the resin substrate includes polycarbonate, a color enhancement absorber and a blue light absorber.

[0049] Specifically, the ratio of the polycarbonate, the color enhancement absorber and the blue light absorber is 1000:0.02:1; for example: the polycarbonate, the color enhancement absorber and the blue light absorber The parts by weight are respectively polycarbonate 1000g, color enhancing absorbent 0.02g, and blue light absorbent 1g.

[0050]As an optimization of the color-enhancing absorber and the blue light absorber, the color-enhancing absorber is selected from a terephthalic acid organic framework compound; the blue light absorber is selected from a rare earth ion organic framework compound. Through the research on the absorption mechanism of various absorbers, a variety of absorbers that can efficiently abs...

Embodiment 2

[0054] This embodiment provides a processing method for a high-definition color enhancement and anti-blue light lens, which includes the following steps:

[0055] (1) Prepare polycarbonate pellets, blue light absorbers and color-enhancing absorbers;

[0056] (2) Pour the polycarbonate pellets, the blue light absorber and the color-enhancing absorber into a three-dimensional mixer and mix for 1 hour to obtain a uniformly dispersed mixture;

[0057] (3) Put the mixture into a drying oven, set the temperature at 120°C, and dry for 4 hours; then heat to 280°C to obtain a molten mixture;

[0058] (4) Injecting the molten mixture into a lens mold preheated to 80°C for injection molding to obtain a lens;

[0059] (5) cooling the lens to room temperature to eliminate the thermal stress of injection molding to obtain a molded lens;

[0060] (6) inserting the molded lens into the frame through ultrasonic cleaning, dipping into the hardening solution and drying to obtain the hardened l...

Embodiment 3

[0068] This embodiment provides a processing method for a high-definition color enhancement and anti-blue light lens, which includes the following steps:

[0069] (1) Prepare polycarbonate pellets, blue light absorbers and color-enhancing absorbers;

[0070] (2) Pour the polycarbonate pellets, the blue light absorber and the color-enhancing absorber into a three-dimensional mixer and mix for 2 hours to obtain a uniformly dispersed mixture;

[0071] (3) Put the mixture into a drying oven, set the temperature at 125°C, and dry for 3 hours; then heat to 250°C to obtain a molten mixture;

[0072] (4) Injecting the molten mixture into a lens mold preheated to 90°C for injection molding to obtain a lens;

[0073] (5) cooling the lens to room temperature to eliminate the thermal stress of injection molding to obtain a molded lens;

[0074] (6) inserting the molded lens into the frame through ultrasonic cleaning, dipping into the hardening solution and drying to obtain the hardened ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com