Suction type sewer scavenger with excavating

A technology for suction pipes and vehicles, which is applied in the direction of mechanically driven excavators/dredgers, etc., which can solve the problems that are not mentioned, cannot be unloaded cleanly, and cannot realize the excavation of compacted materials, so as to ensure stability and safety High performance, realize the effect of digging and suction collection, all-round suction without dead ends

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

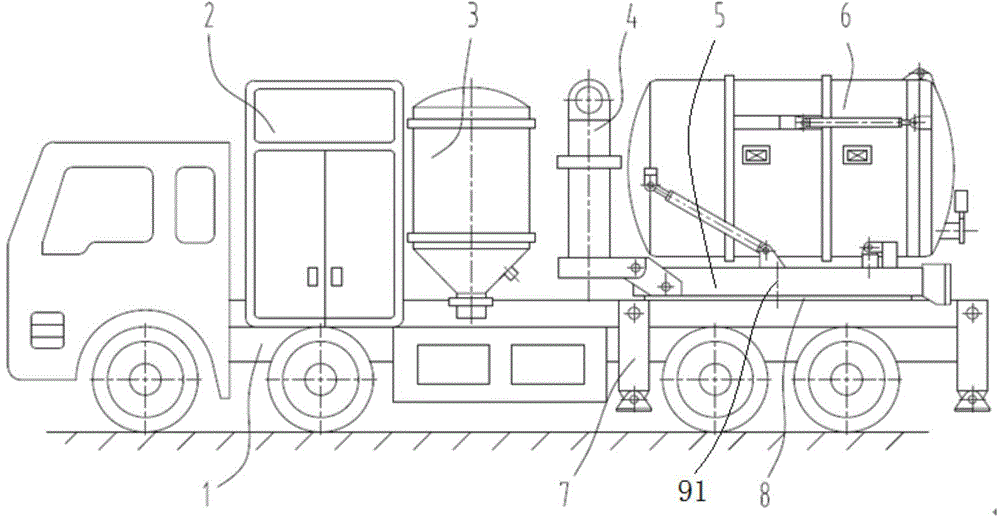

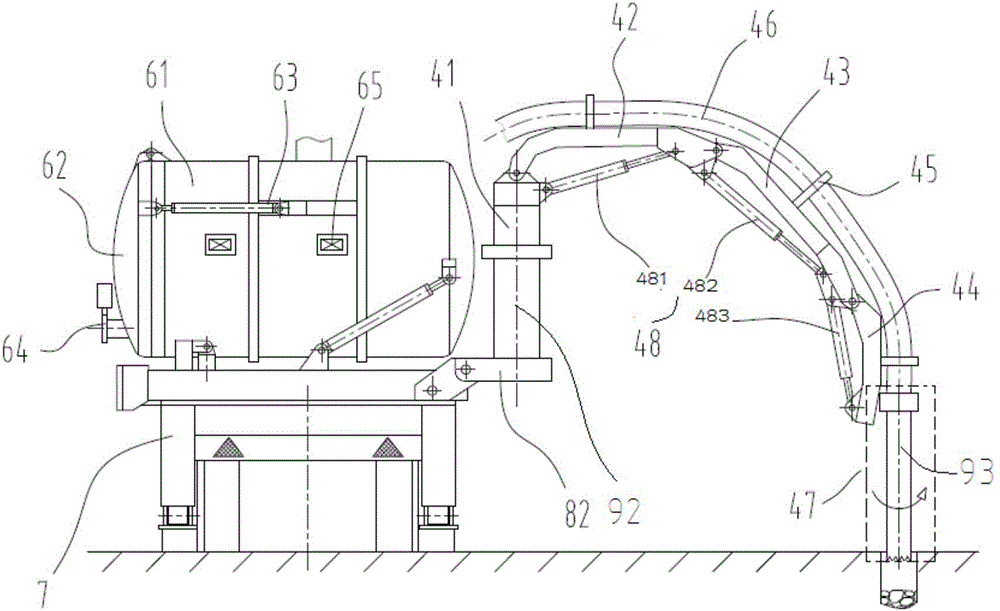

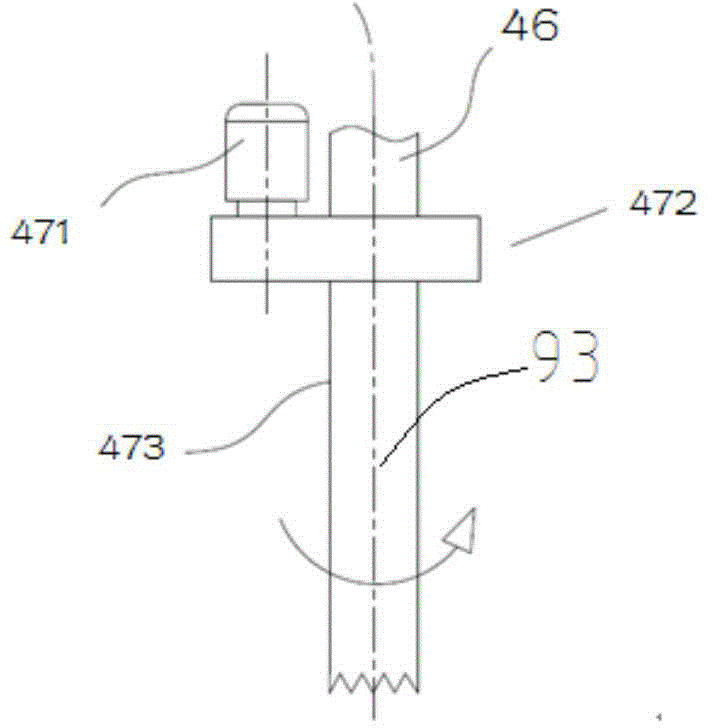

[0031] Such as figure 1 with figure 2 As shown, the present invention provides an excavation suction vehicle, which includes a vehicle chassis 1, a vacuum unit 2 and a filter device 3, and the vacuum unit 2 and the filter device 3 are all arranged on the vehicle chassis 1, and the vacuum unit 2 Connected with the filter device 3, the excavation suction vehicle also includes a slewing device 8, a suction arm 4, a discharge device 5 and a storage tank 6; the slewing device 8 includes a slewing bearing 81 and a bracket 82 (such as Figure 5 shown), the bracket 82 is fixed above the slewing bearing 81, the slewing bearing 81 is arranged on the vehicle chassis 1, and can rotate around the first central axis 91, driving the bracket fixed above the slewing bearing 81 82 to rotate; the suction arm 4 is arranged on one side of the bracket 82 to excavate and crush the material, the unloading device 5 is arranged on the other side of the bracket 82, and the storage tank 6 is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com