Steel tube bundle wrapped aerated plate structure and construction method thereof

A technology of steel pipe bundles and aerated plates, applied to building components, building structures, walls, etc., can solve problems such as low efficiency and easy cracking, and achieve the effects of improving stability, reducing cracking, and ensuring structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

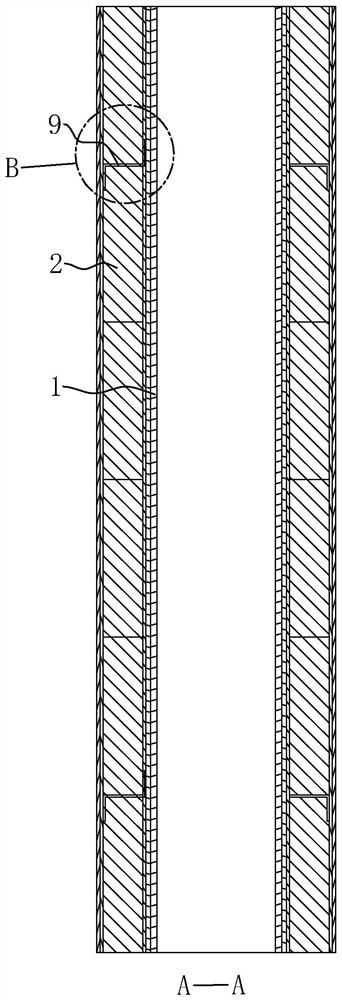

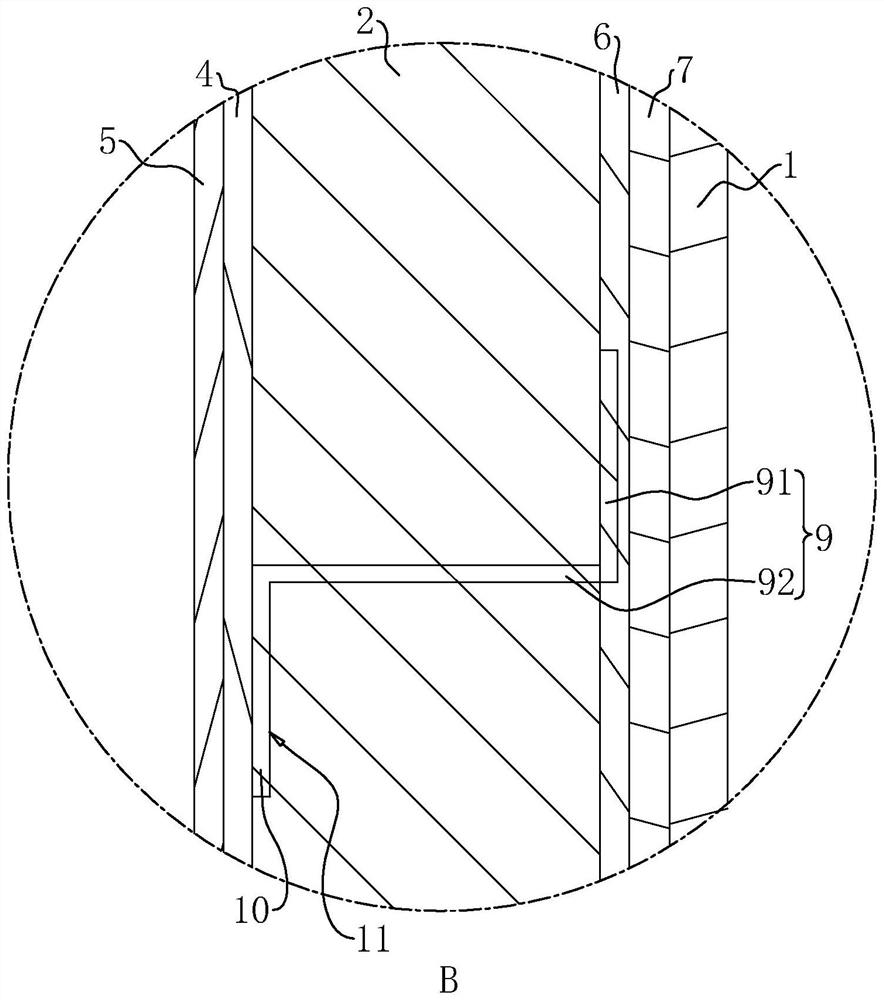

[0041] The following is attached Figure 1-5 The application is described in further detail.

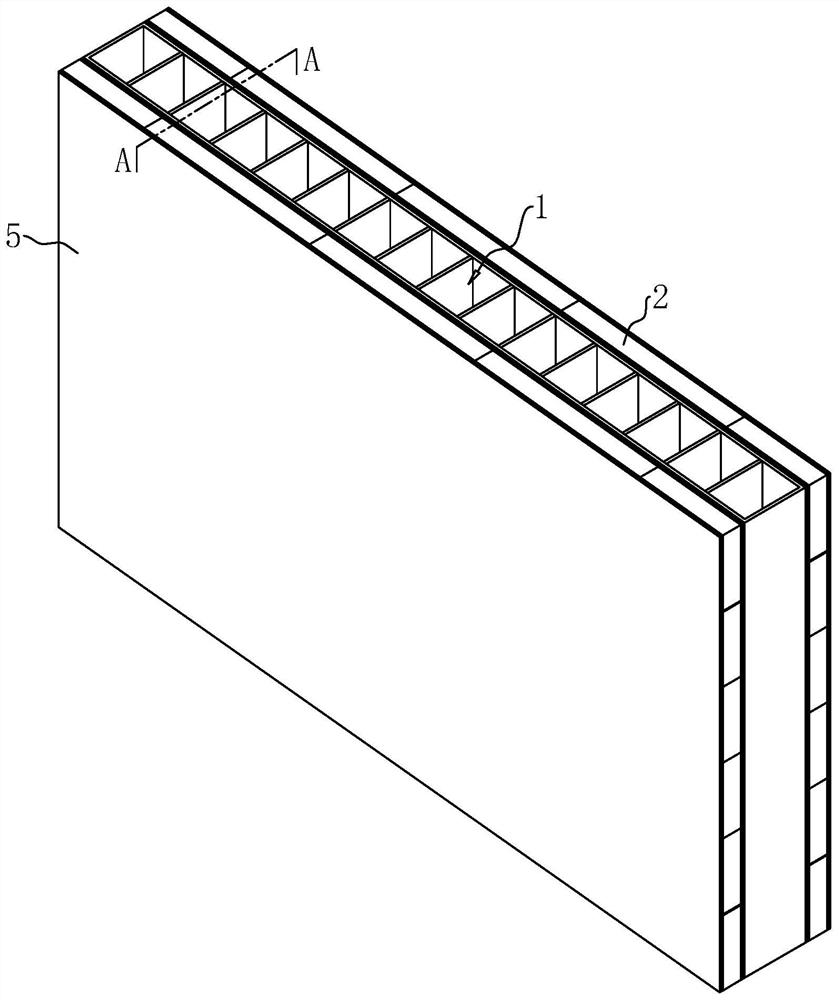

[0042] The embodiment of the present application discloses a structure of a steel pipe bundle wrapped with an air-entraining plate. refer to figure 1 and figure 2 , the steel pipe bundle outsourcing aerated plate structure includes a steel pipe bundle 1 and a plurality of aerated plates 2, the steel pipe bundle 1 is formed by welding a number of hollow steel pipes with a rectangular horizontal section in a row, the steel pipes and the steel pipe bundle 1 are vertically arranged, and at the same time The inside of the steel pipe is filled with reinforced concrete to ensure the support strength of the steel pipe bundle 1 as a support.

[0043] refer to figure 2 and image 3 , the aeration plate 2 is in the shape of a rectangular plate and can be prefabricated in advance. The thickness of the aeration plate 2 is 38-42mm. The aeration plate 2 is attached to the two sides of the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com