Dispersion system of SBS modified emulsified asphalt, coating and preparation method

A dispersion system and emulsified asphalt technology, which is applied in asphalt coatings, coatings, etc., and can solve the problems of poor storage stability of emulsions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

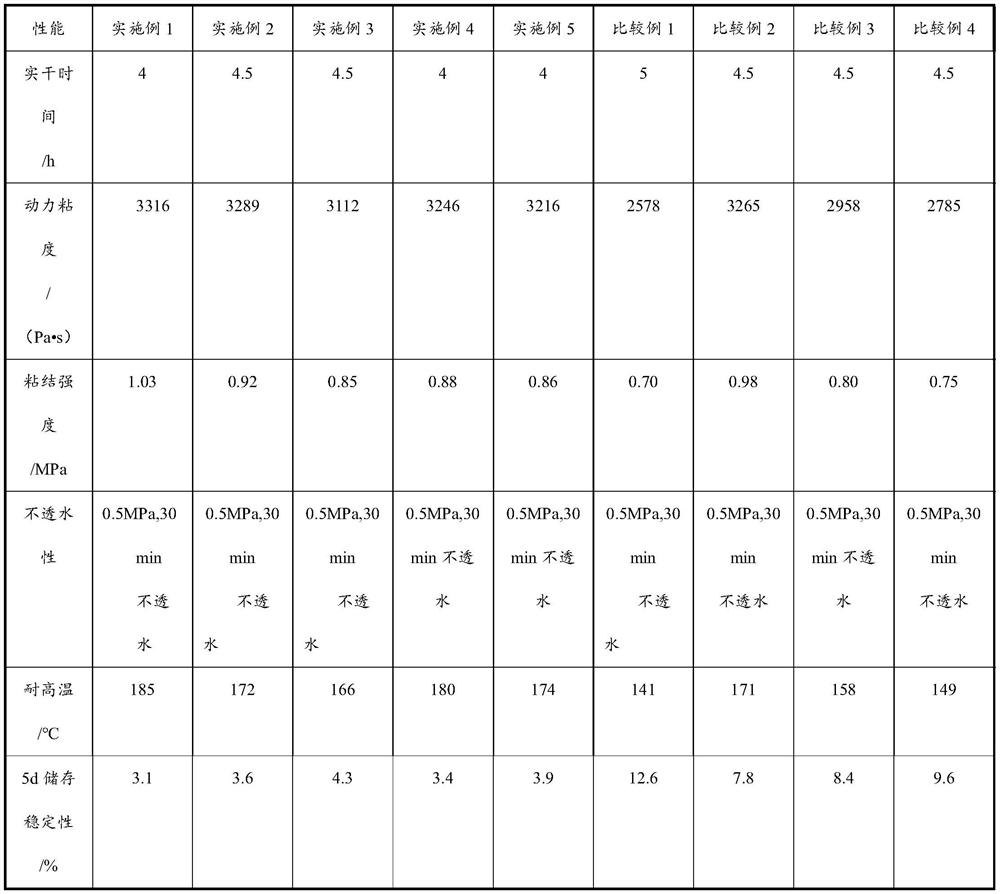

Examples

Embodiment 1

[0048] (1) Heat 50 parts by mass of asphalt to a molten state at 180°C, then add 5 parts by mass of SBS modifier and 3 parts by mass of o-cresyl glycidyl ether, and stir at constant temperature for 2 hours to fully melt and mix to obtain a mixture a.

[0049] (2) Pour 5 parts by mass of stearylamine polyoxyethylene ether diquaternary ammonium emulsifier into 50 parts by mass of deionized water, stir at 80° C. for 1 hour until uniformly mixed to obtain soap liquid.

[0050] (3) Add mixture A and soap solution to the integrated colloid mill emulsifier at the same time, and shear and emulsify the mixture for 3 hours at a speed of 4500r / min to prepare an emulsion.

[0051] (4) Add 2.5 parts by mass of nano-ZnO to the emulsion, and continue to shear for 2 hours at a speed of 3000 r / min using an integrated colloid mill emulsifier.

[0052] (5) Finally, 3 parts by mass of vinyltriethoxysilane crosslinking agent was added, and stirred for 2 hours to obtain a modified emulsified aspha...

Embodiment 2

[0054] (1) Heat 50 parts by mass of asphalt to a molten state at 180°C, then add 10 parts by mass of SBS modifier and 2 parts by mass of o-cresyl glycidyl ether, and stir at constant temperature for 1 hour to fully melt and mix to obtain a mixture a.

[0055] (2) Pour 3 parts by mass of octadecylamine polyoxyethylene ether diquaternary ammonium emulsifier into 50 parts by mass of deionized water, stir at 80° C. for 1 hour until uniformly mixed to obtain soap liquid.

[0056] (3) Add mixture A and soap solution to the integrated colloid mill emulsifier at the same time, and shear and emulsify the mixture for 3 hours at a speed of 4500r / min to prepare an emulsion.

[0057] (4) Add 2 parts by mass of nano-ZnO to the emulsion, and continue to shear at 3000r / min for 2 hours with an integrated colloid mill emulsifier.

[0058] (5) Finally, 2 parts by mass of vinyltriethoxysilane crosslinking agent was added, and stirred for 2 hours to obtain a modified emulsified asphalt waterproof...

Embodiment 3

[0060] (1) Heat 50 parts by mass of asphalt to a molten state at 180°C, then add 15 parts by mass of SBS modifier and 1 part by mass of o-cresyl glycidyl ether, and stir at constant temperature for 2 hours to fully melt and mix to obtain a mixture a.

[0061] (2) Pour 5 parts by mass of stearylamine polyoxyethylene ether diquaternary ammonium emulsifier into 50 parts by mass of deionized water, stir at 80° C. for 1 hour until uniformly mixed to obtain soap liquid.

[0062] (3) Add mixture A and soap solution to the integrated colloid mill emulsifier at the same time, and shear and emulsify the mixture for 3 hours at a speed of 4500r / min to prepare an emulsion.

[0063] (4) Add 1 part by mass of nano-ZnO to the emulsion, and continue to shear at 3000r / min for 2 hours with an integrated colloid mill emulsifier.

[0064] (5) Finally, 2 parts by mass of vinyltriethoxysilane crosslinking agent was added, and stirred for 2 hours to obtain a modified emulsified asphalt waterproof co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com