A cutting fluid cooling and degreasing device for CNC machine tools for machining

A CNC machine tool and machining technology, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve the problems of metal swarf doping, single degreasing function, poor degreasing efficiency, etc., to achieve accelerated cooling , The connection structure is simple, and the effect of easy recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

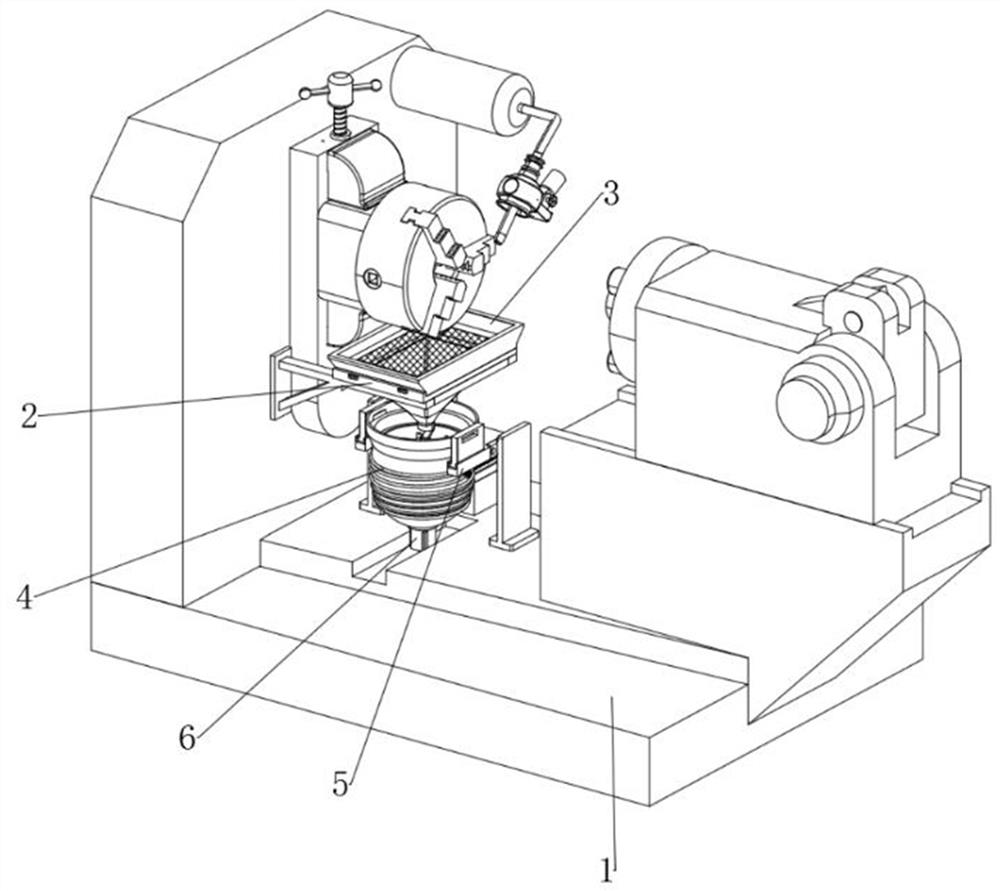

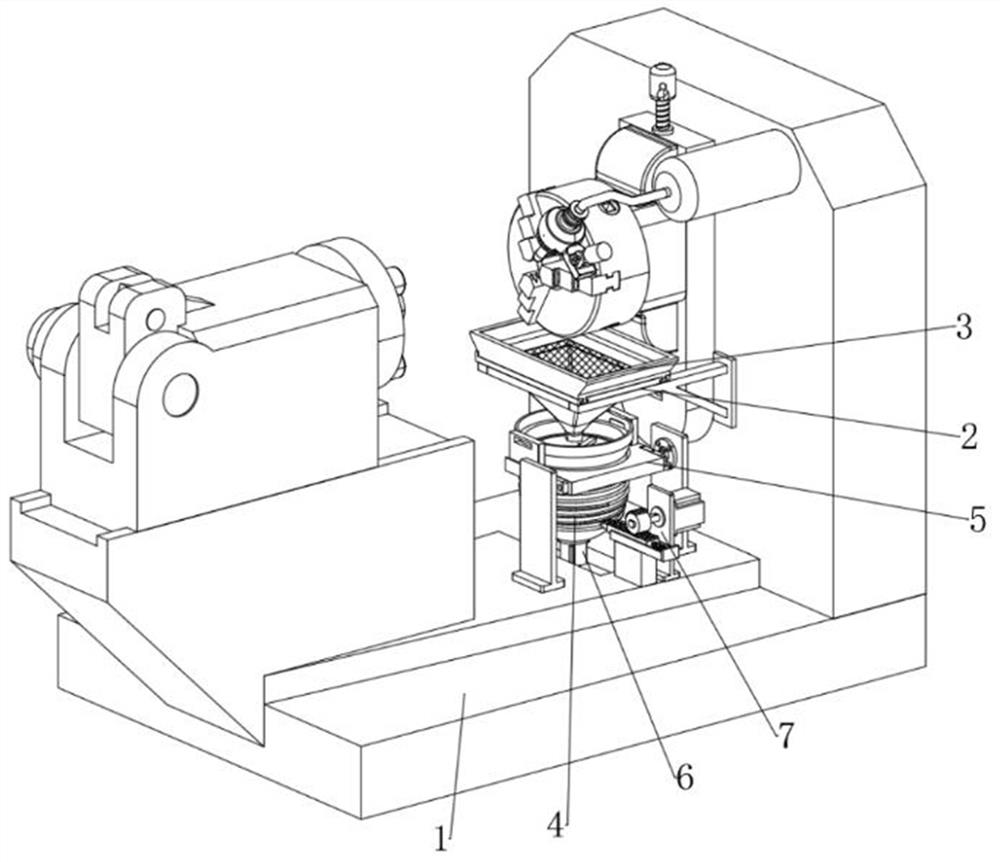

[0038] as attached figure 1 to the attached Image 6 Shown: the present invention provides a cutting fluid cooling and degreasing device for CNC machine tools for machining, comprising a worktable 1; a collection groove 2 is provided at the front end of the vertical frame of the worktable 1, and a mounting frame is provided on the collection groove 2 3; The top of the bottom frame of the workbench 1 is provided with a collection barrel 4, and the collection barrel 4 is provided with a turret 5, and the turret 5 is connected with the bottom frame of the workbench 1 through two vertical plates; the bottom of the collection barrel 4 is provided with There is a first servo motor 6 , a swing mechanism 7 is provided on the right side of the collecting barrel 4 ;

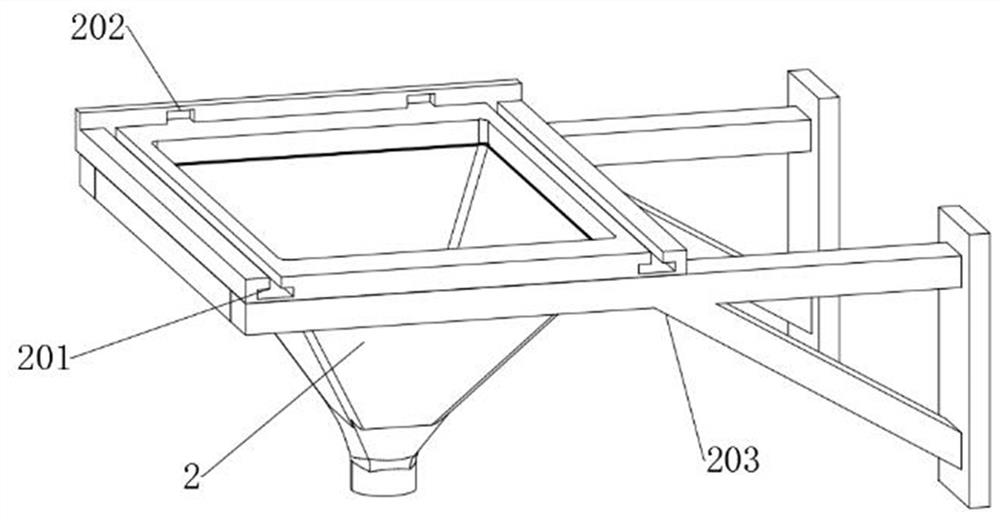

[0039] like image 3 and Figure 4 As shown, the collection tank 2 includes a first chute 201, a bayonet 202 and a support frame 203. The collection tank 2 is fixedly connected to the workbench 1 through the support fra...

Embodiment 2

[0044] like Figure 7 Shown: the rocking mechanism 7 includes a second servo motor 701, a missing gear 702, a sliding frame 703, a rack 704 and a compression spring 705. The end of the rotating shaft of the second servo motor 701 is provided with a missing gear 702, and below the missing gear 702 is provided There is a sliding frame 703, the sliding frame 703 is a rectangular groove structure, and the sliding frame 703 is provided with a rack 704, and a compression spring 705 is arranged between the rack 704 and the right end side wall of the sliding frame 703, and the gear 702 and the rack are missing. 704 is meshed and connected, and the left end of the rack 704 is rotatably connected to the collecting bucket 4 through a pin shaft. The device is powered by the second servo motor 701, and is driven by the missing gear 702 and the rack 704, and the rack 704 can slide along the sliding frame 703. At the same time, the rack 704 drives the collection bucket 4 to move in an arc wi...

Embodiment 3

[0046] like Figure 8 to Figure 10 Shown: the first servo motor 6 includes a rotating shaft 601 and a stirring blade disc 602, and a rotating shaft 601 is rotatably installed on the first servo motor 6, and the rotating shaft 601 penetrates the bottom of the collecting bucket 4 and is arranged in its interior, rotating The shaft 601 is provided with a stirring blade disk 602, and the stirring blade disk 602 is located in the oil removal cylinder 8; the oil removal cylinder 8 includes a fixing frame 801 and an adsorption cotton plate 802, and the oil removal cylinder 8 is a cylindrical through-cavity structure, and the removal of The bottom of the oil cylinder 8 is provided with an adsorption cotton plate 802, and the top of the oil removal cylinder 8 is provided with a fixed frame 801. The rotating shaft 601 penetrates the middle position of the suction cotton plate 802, and the rotating shaft 601 is rotatably connected with the fixed frame 801 through a bearing; 9 includes a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com