Structure with conductive pattern and method for manufacturing same

A manufacturing method and structure technology, which can be used in cable/conductor manufacturing, printed circuit manufacturing, radiation element structure, etc., can solve the problems of requiring photoresist materials, complexity, and many processes, and achieve a simple interlayer The effect of tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

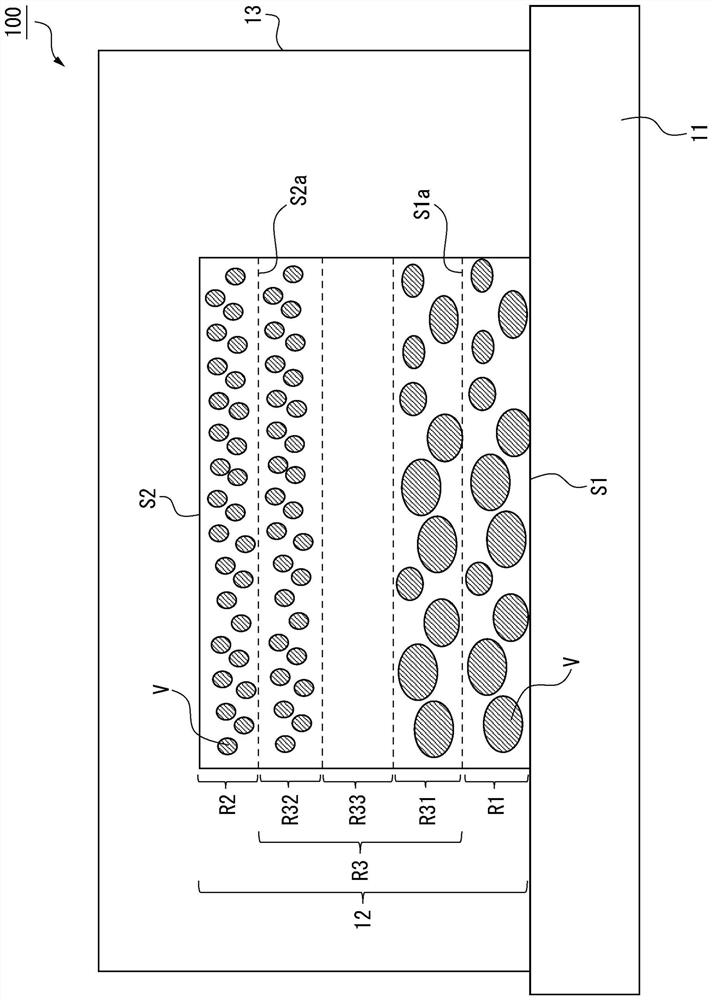

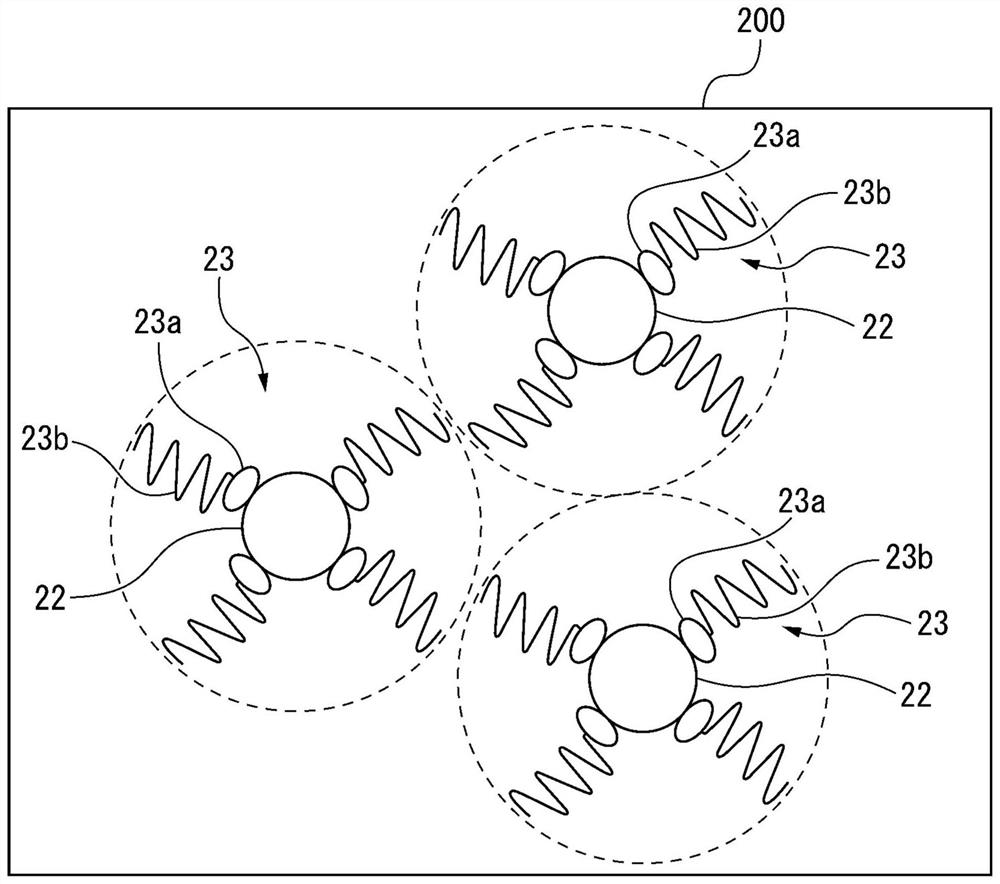

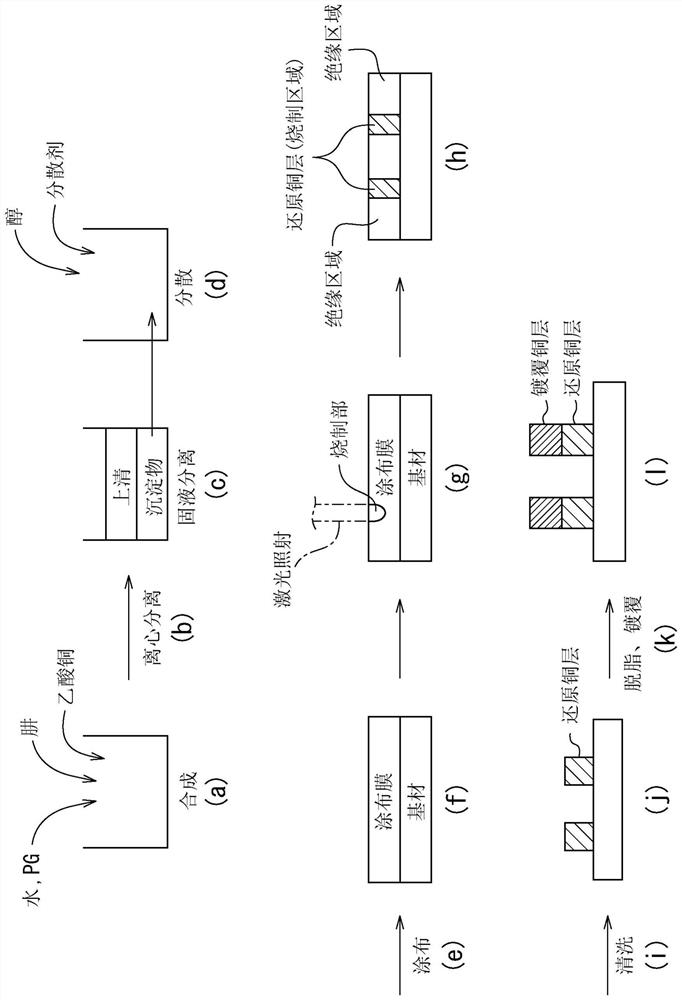

[0234] Dissolve 806 g of copper acetate (II) monohydrate (manufactured by Kanto Chemical Co., Ltd.) in a mixed solvent of 7560 g of distilled water (manufactured by Kyoei Pharmaceutical Co., Ltd.) and 3494 g of 1,2-propanediol (manufactured by Kanto Chemical Co., Ltd.). The thermostat keeps the liquid temperature at -5°C. Add 235 g of hydrazine monohydrate (manufactured by Tokyo Chemical Industry Co., Ltd.) over 20 minutes, stir in a nitrogen atmosphere for 30 minutes, then set the liquid temperature to 25° C. with an external thermostat, and stir in a nitrogen atmosphere for 90 minutes. After stirring, the supernatant and the precipitate were separated by centrifugation. 13.7 g of Disper BYK-145 (manufactured by BYK Chemicals, a phosphoric acid group-containing organic compound) (dispersant content 4 g) and 907 g of ethanol (manufactured by Kanto Chemical Co., Ltd.) were added to 390 g of the obtained precipitate, and the mixture was used in a nitrogen atmosphere. Dispersion...

Embodiment 2

[0245] The dispersion obtained in the same manner as in Example 1 was applied to a polyimide film (manufactured by Toray-DuPont, KAPTON500H, thickness 125 μm) by spin coating, and kept in an oven at 90° C. for 2 hours. The solvent in the film evaporated, and Sample 2 was obtained. The coating film thickness of the obtained sample 2 was 1000 nm.

[0246] Using a Galvano scanner, irradiate laser light (pulse wave oscillation, 532 nm) to the coating film of sample 2 while moving the focus position at a maximum speed of 4500 mm / min, thereby obtaining a desired size of 0.5 mm × 5 mm. Conductive pattern area (copper-containing film). The coating film remained in the area not irradiated with laser light.

[0247] The cross-section of copper in the conductive pattern region was observed by SEM. As a result, the thickness was 0.5 μm, and the porosity was 40% by volume in the region on the first main surface side. In addition, the resistance value of the conductive pattern region was...

Embodiment 3

[0252] The dispersion obtained in the same manner as in Example 1 was applied to a polyimide film (manufactured by Toray-DuPont, KAPTON500H, thickness 125 μm) by spin coating, and kept in an oven at 90° C. for 2 hours. The solvent in the film evaporated, and Sample 3 was obtained. The coating film thickness of the obtained sample 3 was 1000 nm.

[0253] Using a Galvano scanner, irradiate laser light (pulse wave oscillation, 532 nm) to the coating film of sample 3 while moving the focus position at a maximum speed of 1200 mm / min, thereby obtaining a desired size of 0.5 mm × 5 mm. Conductive pattern area (copper-containing film). The coating film remained in the area not irradiated with laser light.

[0254] The cross-section of copper in the conductive pattern region was observed by SEM, and the thickness was 0.5 μm, and the porosity was 11.7% by volume in the region on the first main surface side. In addition, the resistance value of the conductive pattern region was 30 μΩc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com