Multilayer ceramic capacitor

A technology of multilayer ceramics and capacitors, applied in the field of capacitors, can solve the problems of increased electric field concentration, breakdown and burnout of multilayer ceramic capacitors, etc., and achieve the effects of reducing electric field concentration, good voltage resistance performance, and eliminating charge concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

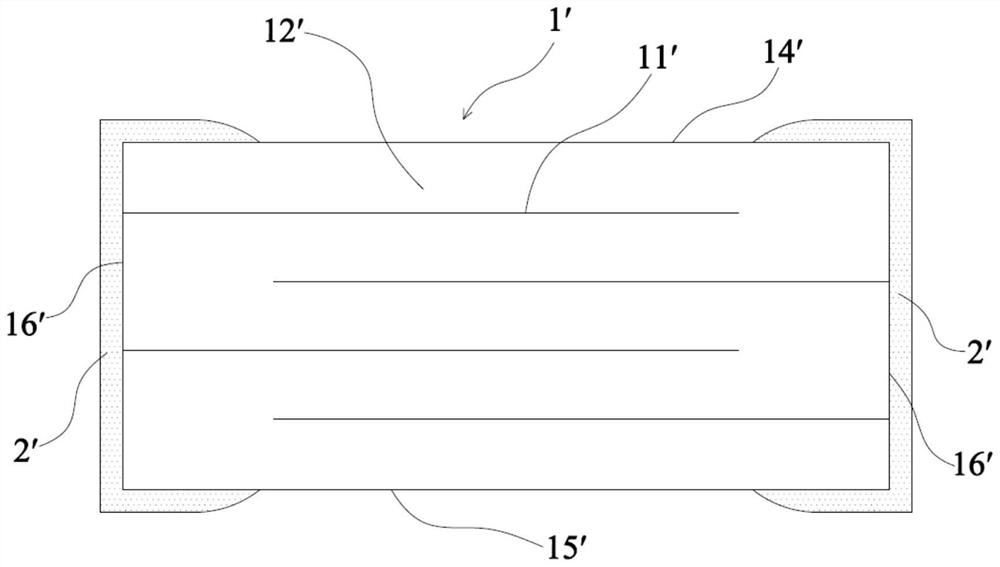

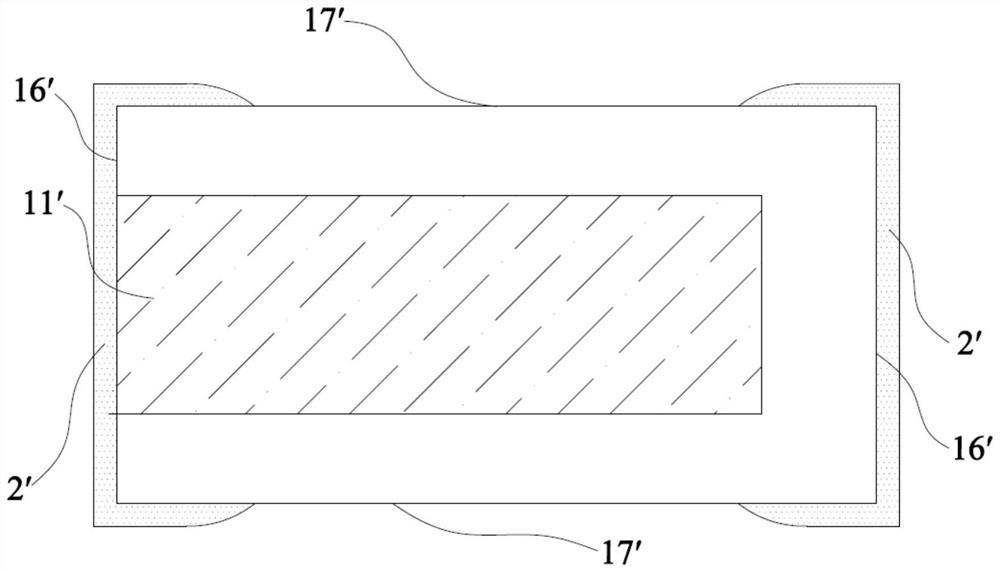

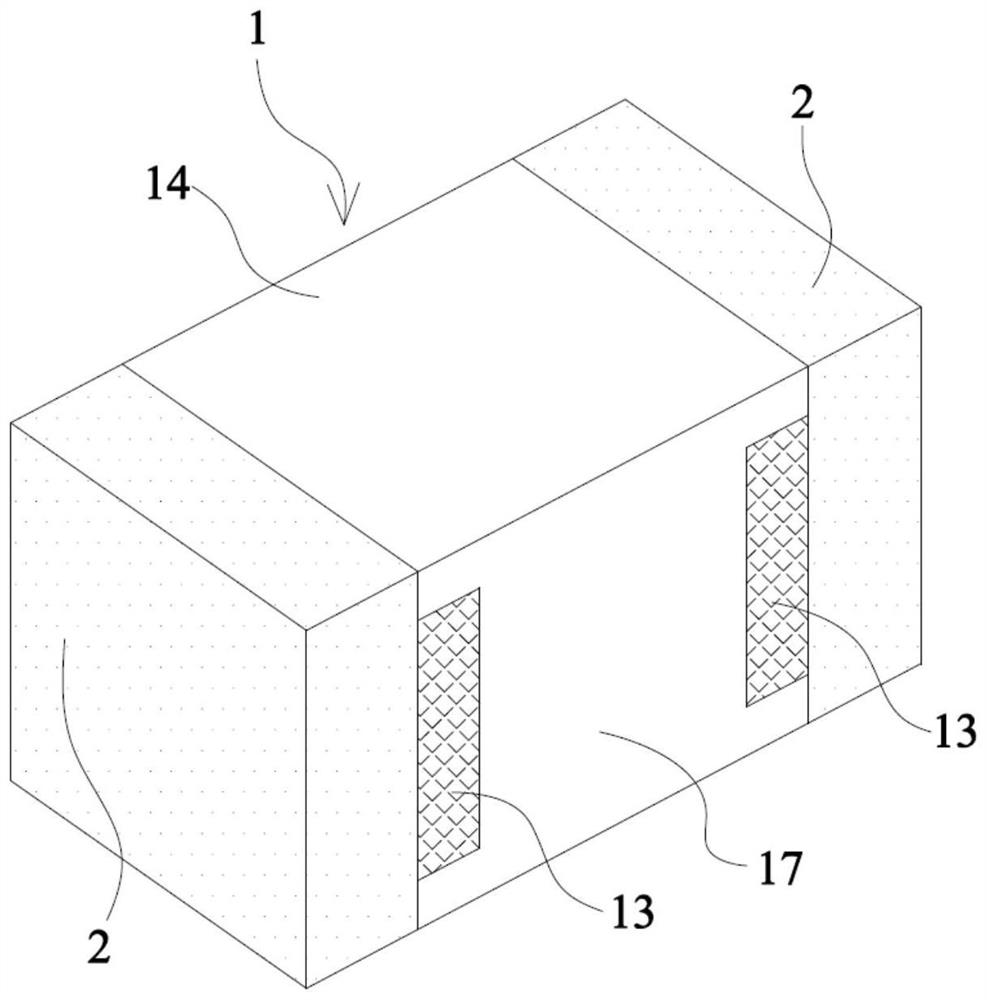

[0031] Please refer to Figure 3-Figure 5 , a multilayer ceramic capacitor in a preferred embodiment of the embodiment of the present invention includes a ceramic body 1 and terminal electrodes 2 disposed on both end surfaces 16 of the ceramic body 1, and the terminal electrodes 2 also extend to the upper surface 14 and the lower surface of the ceramic body 1. surface 15 and two side surfaces 17, and the ends of the two terminal electrodes 2 are arranged oppositely with a distance between them, the ceramic body 1 also includes an internal electrode 11, a dielectric layer 12 and an additional electrode 13, the internal electrodes 11 are arranged in parallel and A dielectric layer 12 is arranged between two adjacent internal electrodes 11, and the additional electrodes 13 are arranged at both ends of the side surfaces 17 of the ceramic body 1, and the additional electrodes 13 are exposed on the side surfaces 17 of the ceramic body 1, and the additional electrodes 13 and The term...

Embodiment 2

[0063] The difference between the multilayer ceramic capacitor provided in Embodiment 2 and Embodiment 1 is that please refer to Image 6 , the end of the additional electrode 13 is semicircular in the downward cross-section, and the connection between one end of the additional electrode 13 and the terminal electrode 2 is located at the end surface 16 of the ceramic body 1 .

Embodiment 3

[0065] The difference between the multilayer ceramic capacitor provided in the third embodiment and the first embodiment is that please refer to Figure 7 , the additional electrode 13 is not connected to the two end surfaces 16, and the two ends of the additional electrode 13 are arc-shaped.

[0066] To sum up, the embodiment of the present invention provides a multilayer ceramic capacitor, which provides an additional electrode 13 between the end of the terminal electrode 2 and the end of the internal electrode 11, and the surface of the additional electrode 13 facing the internal electrode 11 is a curved surface, eliminating the need for terminal The charge concentration at the end of the electrode 2 can significantly reduce the electric field concentration, even if the area of the internal electrode 11 is increased to obtain a high capacitance so that the distance between the end of the internal electrode 11 and the end of the terminal electrode 2 is reduced, it can ensur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com