Voltage-resistant piezoelectric ceramic material and preparation method thereof

A piezoelectric ceramic and voltage-resistant technology, which is applied in the field of voltage-resistant piezoelectric ceramic materials and their preparation, can solve the problems of cracking of tiles, weak voltage-resistant performance, and increased voltage, and achieves low cost, excellent voltage-resistant performance, simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

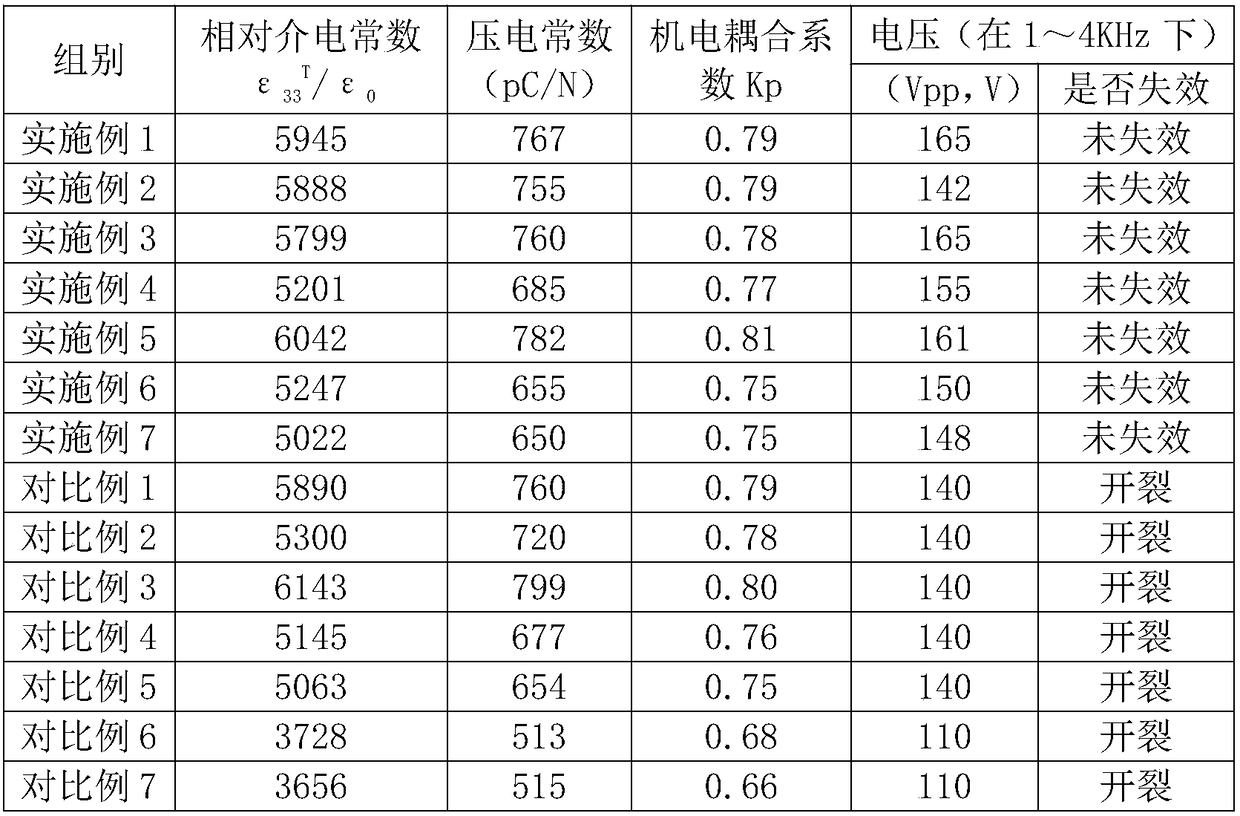

Examples

Embodiment 1

[0034] A voltage-resistant piezoelectric ceramic material, the piezoelectric ceramic material is made of Pb 3 o 4 , ZrO 2 、TiO 2 , ZnO, Nb 2 o 5 、Ni 2 o 3 , Sb 2 o 3 , SrCO 3 Made of anti-pressure agent, the component formula is: 0.75Pb(Zr,Ti)O 3 -0.05Pb(Zn 1 / 3 Nb 2 / 3 )O 3 -0.15Pb(Ni 1 / 3 Nb 2 / 3 )O 3 -0.05Pb(Sb 1 / 3 Nb 2 / 3 )O 3 +xwt%SrCO 3 +ywt% pressure resistant agent.

[0035] Further, in the composition formula, the proportion of niobium zinc-niobium nickel-niobium antimony-lead zirconate titanate pentad system is 93wt%; in the composition formula, Zr / Ti=0.98; x=2.1; y= 0.2; the pressure-resistant agent is a mixture of tungsten trioxide, aluminum oxide and silicon dioxide, wherein WO 3 20wt%, Al 2 o 3 Accounting for 30wt%, SiO 2 Accounting for 50wt%.

[0036] A method for preparing a voltage-resistant piezoelectric ceramic material as described above, comprising the following steps:

[0037] (1) Ingredients, primary ball milling: at room temperature...

Embodiment 2

[0045] A voltage-resistant piezoelectric ceramic material, the piezoelectric ceramic material is made of Pb 3 o 4 , ZrO 2 、TiO 2 , ZnO, Nb 2 o 5 、Ni 2 o 3 , Sb 2 o 3 , SrCO 3 Made of anti-pressure agent, the component formula is: 0.75Pb(Zr,Ti)O 3 -0.05Pb(Zn 1 / 3 Nb 2 / 3 )O 3 -0.15Pb(Ni 1 / 3 Nb 2 / 3 )O 3 -0.05Pb(Sb 1 / 3 Nb 2 / 3 )O 3 +xwt%SrCO 3 +ywt% pressure resistant agent.

[0046] Further, in the composition formula, the proportion of niobium zinc-niobium nickel-niobium antimony-lead zirconate titanate pentad system is 98wt%; in the composition formula, Zr / Ti=1.0; x=5.5; y= 0.7; the pressure-resistant agent is a mixture of tungsten trioxide, aluminum oxide and silicon dioxide, wherein WO 3 20wt%, Al 2 o 3 Accounting for 30wt%, SiO 2 Accounting for 50wt%.

[0047] A method for preparing a voltage-resistant piezoelectric ceramic material as described above, comprising the following steps:

[0048] (1) Ingredients, primary ball milling: at room temperature ...

Embodiment 3

[0056] A voltage-resistant piezoelectric ceramic material, the piezoelectric ceramic material is made of Pb 3 o 4 , ZrO 2 、TiO 2 , ZnO, Nb 2 o 5 、Ni 2 o 3 , Sb 2 o 3 , SrCO 3Made of anti-pressure agent, the component formula is: 0.75Pb(Zr,Ti)O 3 -0.05Pb(Zn 1 / 3 Nb 2 / 3 )O 3 -0.15Pb(Ni 1 / 3 Nb 2 / 3 )O 3 -0.05Pb(Sb 1 / 3 Nb 2 / 3 )O 3 +xwt%SrCO 3 +ywt% pressure resistant agent.

[0057] Further, in the composition formula, the proportion of niobium zinc-niobium nickel-niobium antimony-lead zirconate titanate pentad system is 94.78wt%; in the composition formula, Zr / Ti=0.96; x=2.0; y =0.3; the pressure-resistant agent is a mixture of tungsten trioxide, aluminum oxide and silicon dioxide, wherein WO 3 20wt%, Al 2 o 3 Accounting for 30wt%, SiO 2 Accounting for 50wt%.

[0058] A method for preparing a voltage-resistant piezoelectric ceramic material as described above, comprising the following steps:

[0059] (1) Ingredients, primary ball milling: at room temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com