Titanium alloy pickling passivation processing technology

A processing technology and titanium alloy acid technology, which is applied in the field of titanium alloy pickling and passivation processing technology, can solve the problems of affecting the surface passivation treatment of titanium alloy and poor pickling effect of titanium alloy, so as to reduce the difficulty of management and control and ensure uniformity sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] see Figure 1-9 Shown, a kind of titanium alloy pickling passivation processing technology comprises the following steps:

[0041]Step 1. Pass pickling liquid into the pickling pool 10, wherein the pickling liquid is formed by mixing nitric acid and hydrofluoric acid according to the mass ratio of 15:1, and pass a passivating agent into the passivating pool 20, and the passivating agent adopts commercially available The chromium-free passivating agent sold, feeds deionized water in the cleaning tank 30;

[0042] Step 2: Put the titanium alloy parts into the discharge rack 401 in the discharge mechanism, use the sliding assembly to drive the discharge mechanism to slide directly above the pickling tank 10, and then put the discharge mechanism into the pickling tank In 10, two sealing plates 502 are used to seal the pickling pool 10;

[0043] Step 3: Connect one end of the connecting rod 207 to one end of the rotating rod 202 through the connecting assembly, use the ser...

Embodiment 2

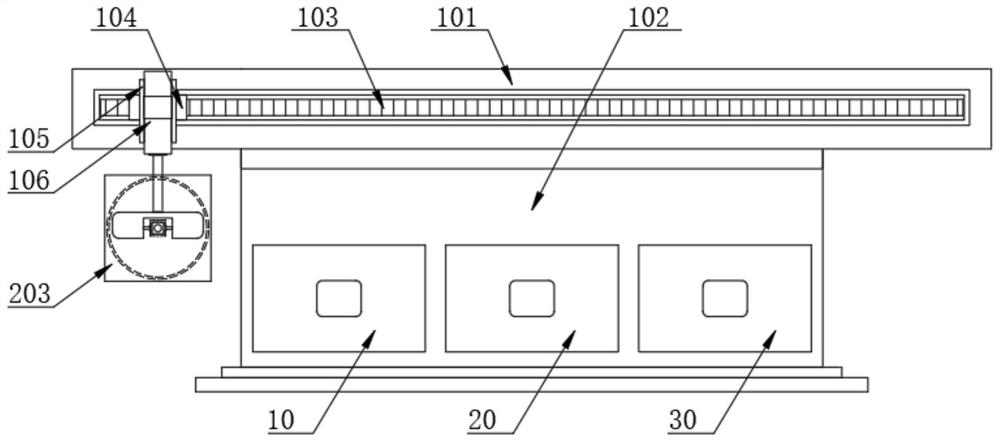

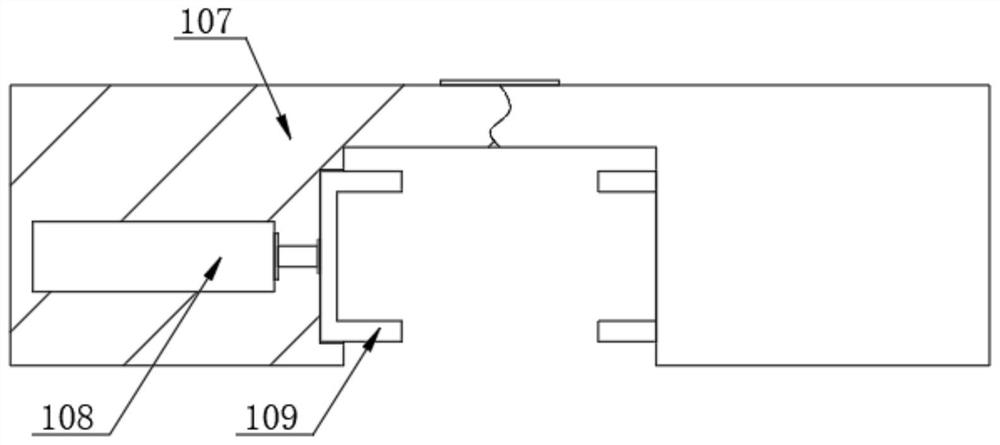

[0048] see Figure 1-9 As shown, the sliding mechanism in the present invention includes a fixed frame 101, the bottom of the fixed frame 101 is provided with a fixed box 102, and the pickling pool 10, the passivation pool 20 and the cleaning pool 30 are all arranged inside the fixed box 102, and the fixed frame 101 The front and rear sides of the inner wall are all provided with linear slide rails 103, and one side of the two linear slide rails 103 is all slidably provided with a linear motor 104, and one side of the two linear motors 104 is provided with a mounting frame 105, and the two mounting frames The inside of 105 is provided with servo electric cylinder 106, and one end of the driving shaft of two servo electric cylinders 106 is provided with installation block 107, and the interior of two installation blocks 107 is all symmetrically provided with two electric push rods 108, two installation Two clamping blocks 109 are arranged symmetrically inside the block 107, and...

Embodiment 3

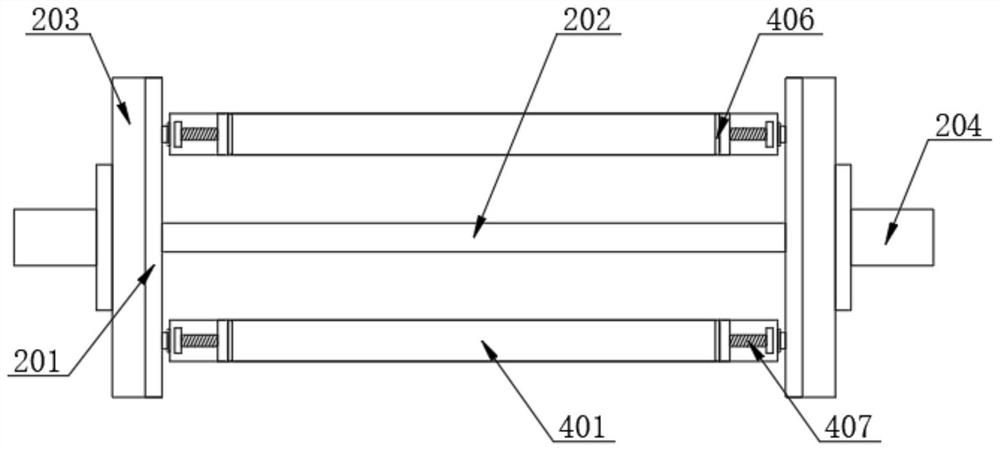

[0051] see Figure 1-9 As shown, the discharging mechanism in the present invention includes a turret 201, two turrets 201 are symmetrically arranged, and the inside of the two turrets 201 is provided with a rotating rod 202, and one side of the two turrets 201 is provided with a movable frame 203, and one side of the two movable frames 203 is provided with a connecting block 204, and the two ends of the rotating rod 202 extend to the inside of the two connecting blocks 204 respectively, and the inside of the connecting block 204 on the right side is provided with a rotating rod 202 is matched with the rotating bearing, and the connection groove 205 is opened inside the left connection block 204, and the connection assembly is located in the connection groove 205. There are servo motors 206, and one end of the output shafts of the three servo motors 206 is provided with a connecting rod 207 through a coupling, and one end of the connecting rod 207 extends to the inside of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com