Composite oxide and preparation method and application thereof

A composite oxide and catalytic reaction technology, applied in the field of catalysis, can solve the problems of difficult regeneration, low isophorone selectivity, and high cost, and achieve the effects of easy industrial scale-up production, inhibition of further condensation, and reduction of side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

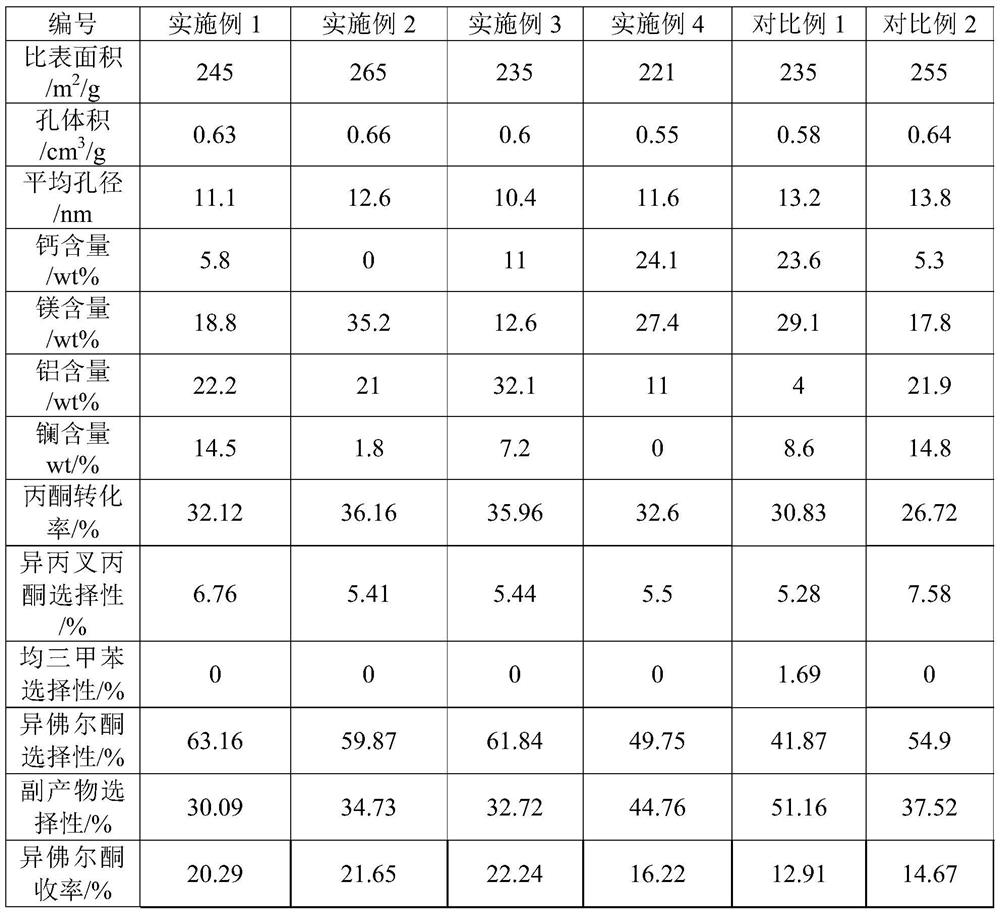

Examples

Embodiment approach

[0044] According to a preferred embodiment of the present invention, the preparation method of the composite oxide is:

[0045] Formulate the Group IIA metal precursor and the lanthanum precursor into a solution C; then prepare a precipitant solution A so that the weight concentration of the precipitant in the precipitant solution is 3-25% by weight; reprepare the aluminum precursor suspension B, and The pH of solution B is 11-12, and the mass ratio of the aluminum precursor to the solvent used to prepare suspension B is 0.1-0.5:1; then solution A and solution C are added to suspension B in parallel to form Mixed system; during the process of preparing the mixed system, keep the temperature of the mixed system at 38-60°C, and based on 1g of aluminum precursor, the addition rate of the lanthanum precursor is 0.2-1g / min, preferably 0.5-0.8g / min; then aging, the aging temperature is preferably 60-100 ° C, the time is preferably 3-15 hours; cooling at a temperature of 25-40 ° C fo...

Embodiment 1

[0055] Get 87.3g magnesium nitrate, 16.1g calcium nitrate and 17.7g lanthanum nitrate and dissolve in 1140g deionized water, be mixed with nitrate solution A, take ammoniacal liquor (weight concentration 25%) subsequently and dilute to weight concentration with deionized water and be 8% by weight , prepared into alkaline solution B, and then mixed 23.3g of pseudo-boehmite with 100g of deionized water and stirred evenly, then dripped ammonia water to adjust the pH to 11 to prepare suspension C. Keep the C suspension at 40 °C and add solutions A and B co-flow to C with stirring while stabilizing the pH at 10. Based on 1 g of pseudo-boehmite, the addition rate of the nitrate solution A was 0.5 g / min; after the addition, the mixed solution was heated to 80° C. and aged for 4 hours. After standing and cooling at 25° C. for 24 hours, solid-liquid separation was carried out, and then the filter cake was washed with deionized water until the pH value of the filtrate was 8. Finally, d...

Embodiment 2

[0057] Get 179.9g magnesium nitrate and 1.5g lanthanum nitrate and dissolve in 2000g deionized water, be mixed with nitrate solution A, then take ammoniacal liquor (weight concentration 25%) and dilute to weight concentration with deionized water to be 15% by weight, be mixed with alkaline solution B, take 20g of pseudo-boehmite and mix with 150g of deionized water and stir evenly, then add ammonia water to adjust the pH to 11 to prepare suspension C. Keep solution C at 60 °C, and add solutions A and B co-flow to C with stirring while stabilizing the pH at 10. Based on 1 g of pseudo-boehmite, the addition rate of the nitrate solution A was 0.8 g / min; after the addition, the mixed solution was heated to 90° C. and aged for 6 hours. After standing and cooling at 30° C. for 12 hours, solid-liquid separation was carried out, and then the filter cake was washed with deionized water until the pH value of the filtrate was 9. Finally, it was dried in an oven at 120° C. for 5 hours, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com