Difunctional ceramic membrane for gas in-situ dry reforming and preparation method thereof

A dual-function, ceramic membrane technology, applied in the field of electrochemistry, can solve problems such as high energy consumption, achieve the effects of improving conversion efficiency, reducing cost and energy consumption, and preventing escape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] In situ dry reforming of carbon dioxide gas

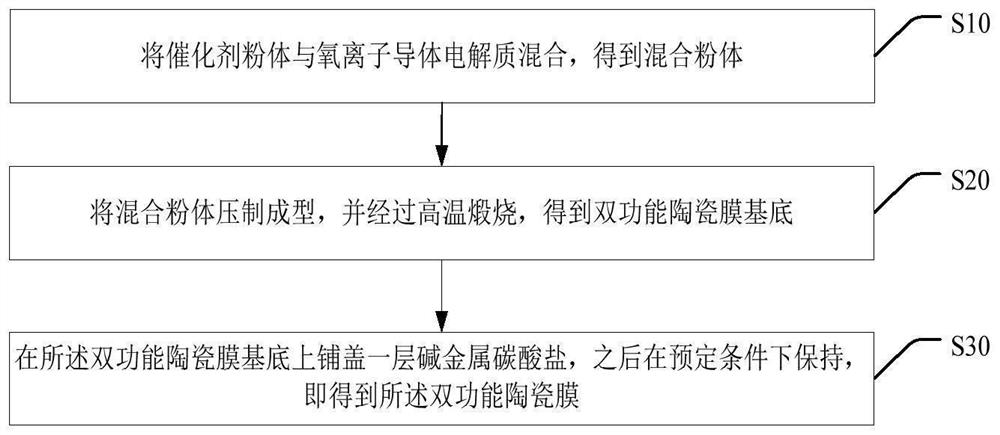

[0058] 1. Preparation of bifunctional ceramic membrane

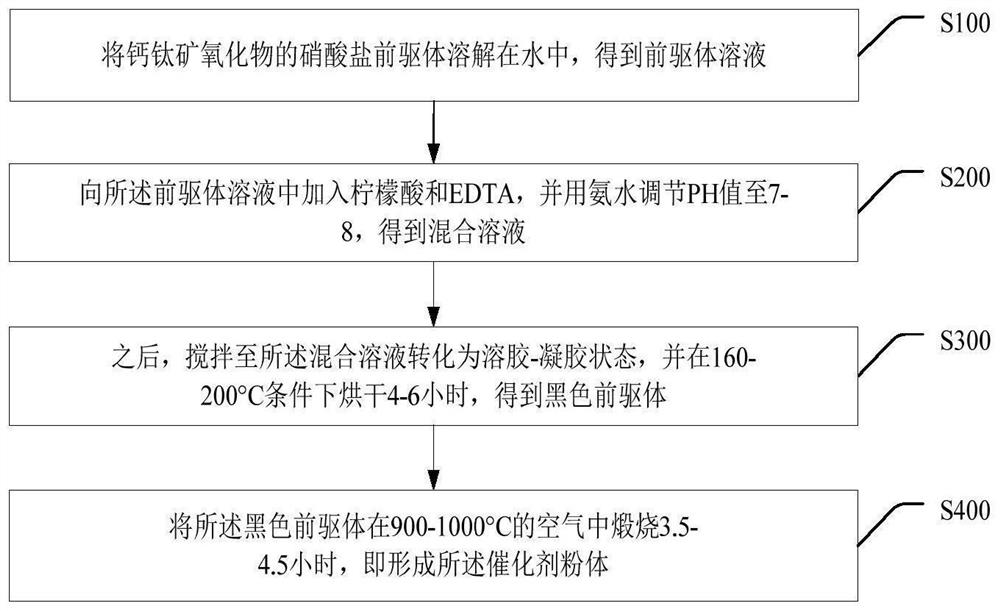

[0059] (1) Dissolve the nitrate precursor of the perovskite oxide containing La, Sr, Fe, Ni ions in water, then add citric acid and EDTA to the solution, and adjust the pH value to 7-8 with ammonia water, then stir until the solution turns into a sol-gel state, and dry at 160-200°C for 4-6 hours to obtain a black precursor;

[0060] (2) Calcining the obtained black precursor in the air at 900-1000°C for 3.5-4.5 hours to obtain the catalyst La 0.7 Sr 0.3 Fe 0.8 Ni 0.2 o 3-δ (LSFN) powder;

[0061] (3) Mix LSFN powder and SDC at a ratio of 3:7, press the mixed LSFN-SDC powder, and calcinate at a high temperature of 1100°C to obtain a bifunctional ceramic membrane substrate;

[0062] (4) Spread a layer of alkali metal carbonate on the substrate (according to the volume ratio of lithium carbonate and potassium carbonate 1:1), keep it at 550°C for 2 hours, and wait f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com