Double-phase soft magnetic ferrite low-frequency wave-absorbing device and preparation method thereof

A soft ferrite and device technology, used in electrical components, antennas, etc., can solve the problems of thick absorber and poor absorber performance, and achieve the effects of high density, low cost, and good corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

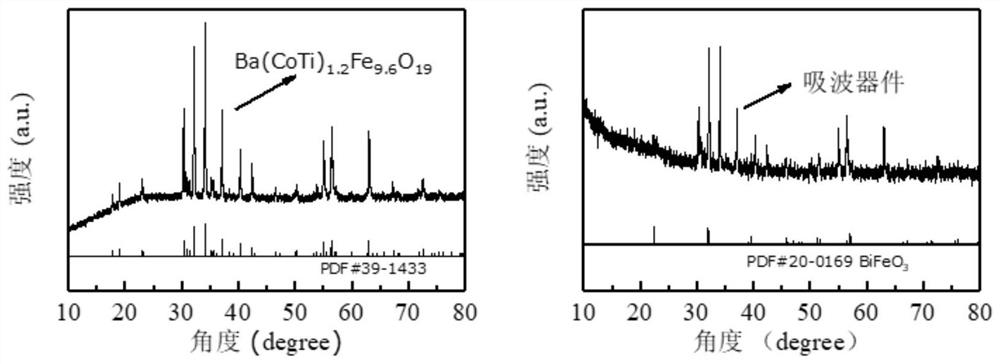

[0037] Embodiment 1. Two-phase soft ferrite low-frequency wave absorbing device Ba(CoTi) X Fe 12-X o 19 -BiFeO 3 The preparation and characterization of

[0038] (1) prepare soft magnetic ferrite powder with solid state reaction method, described soft ferrite is Ba(CoTi) X Fe 12- X o 19 , in this embodiment X is 1.2;

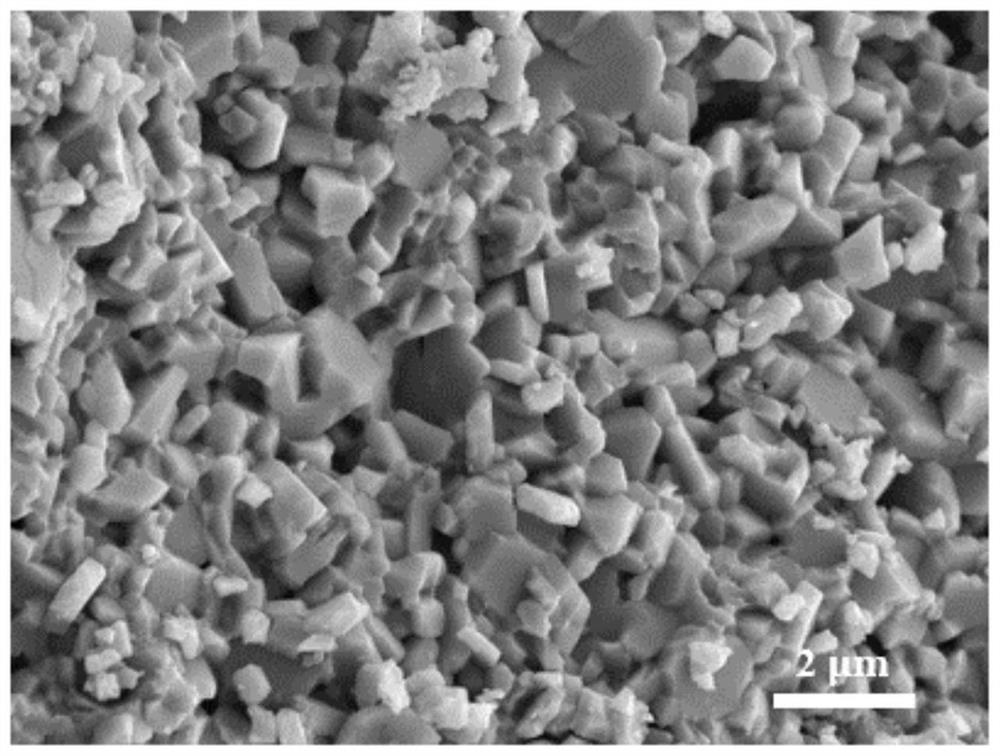

[0039] (2) the soft magnetic ferrite Ba(CoTi) that step (1) obtains is obtained in the mode of adopting planetary ball mill 1.2 Fe 9.6 o 19 The powder is ground and passed through a 300-mesh sieve to obtain Ba(CoTi) with a particle size of 0.1 μm to 2 μm 1.2 Fe 9.6 o 19 Powder; preferably 0.5 μm to 0.8 μm. It should be understood that when preparing Ba(CoTi) in the method of the present invention 1.2 Fe9 .6 o 19 During micropowder, not all of the prepared micropowders fall within the particle size range described here, but most of them, such as more than 80%, preferably more than 90%, fall within the particle size parameter range described here ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com