Lead-free nano composite columnar array structure film with high energy storage density and wide working temperature and preparation method of lead-free nano composite columnar array structure film

A technology with wide operating temperature and high energy storage density, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, hybrid capacitor electrolytes, etc., can solve the problems of increased dielectric loss, reduced energy storage efficiency, and reduced breakdown. , to achieve the effects of increasing the working temperature, increasing the breakdown field strength, and increasing the energy storage density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

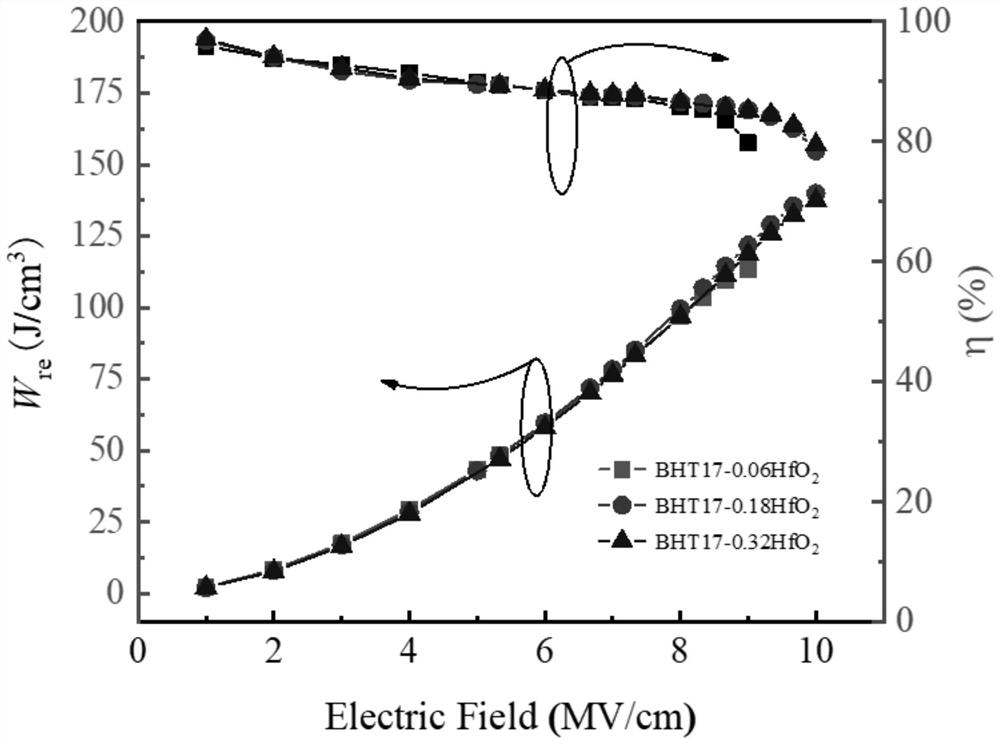

Examples

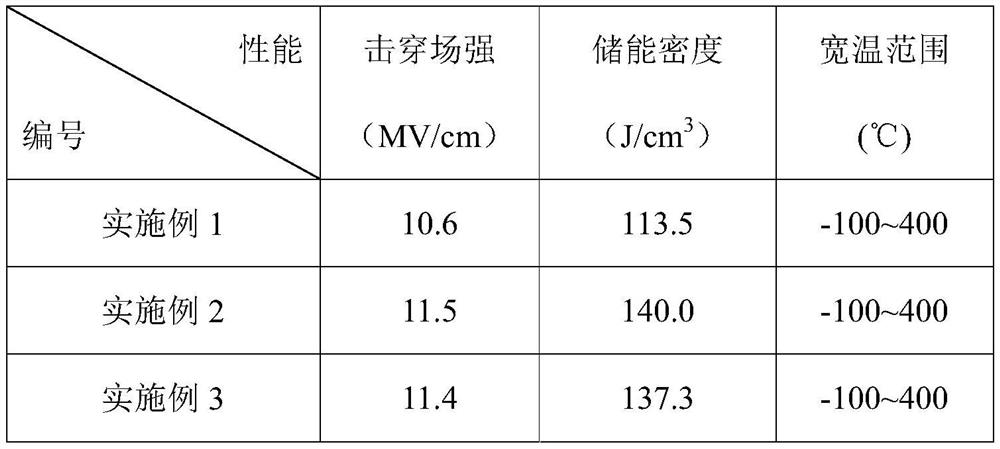

Embodiment 1

[0035] The lead-free nanocomposite columnar array film with high energy storage density and wide working temperature in this embodiment includes the following steps:

[0036] Step 1. Target preparation: for growing BaHf 0.17 Ti 0.83 o 3 -0.06HfO 2 The ceramic target material of the lead-free nanocomposite columnar array structure film adopts BaCO with a purity level of 4N 3 Powder, HfO 2 Powder and TiO 2 The powder is prepared by traditional ceramic technology according to the ratio; when preparing ceramic targets, the sintering temperature is lower than the phase formation temperature of each system by 100°C.

[0037] Step 2, put the substrate, vacuum: Nb:SrTiO 3 The substrate is placed on the heating platform, and the vacuum degree in the deposition chamber is less than 1×10 by using a mechanical pump and a molecular pump. -5 mbar.

[0038] Step 3. Ventilate and heat up: Infuse 200 mbar of argon gas and oxygen gas mixture with a volume ratio of 1 / 1, then raise the te...

Embodiment 2

[0044] The lead-free nanocomposite columnar array film with high energy storage density and wide working temperature in this embodiment includes the following steps:

[0045] Step 1. Target preparation: for growing BaHf 0.17 Ti 0.83 o 3 -0.18HfO 2 The ceramic target material of the lead-free nanocomposite columnar array structure film adopts BaCO with a purity level of 5N 3 Powder, HfO 2 Powder and TiO 2 The powder is prepared by traditional ceramic technology according to the ratio; when preparing ceramic targets, the sintering temperature is lower than the phase formation temperature of each system by 100 °C.

[0046] Step 2, put the substrate, vacuum: Nb:SrTiO 3 The substrate is placed on the heating platform, and the vacuum degree in the deposition chamber is less than 1×10 by using a mechanical pump and a molecular pump. -5 mbar.

[0047] Step 3. Ventilation and temperature rise: 200 mbar of the mixed gas of argon and oxygen with a volume ratio of 1 / 1 was introduc...

Embodiment 3

[0053] The lead-free nanocomposite columnar array film with high energy storage density and wide working temperature in this embodiment includes the following steps:

[0054] Step 1. Target preparation: for growing BaHf 0.17 Ti 0.83 o 3 -0.32HfO 2 The ceramic target material of the lead-free nanocomposite columnar array structure film adopts BaCO with a purity level of 5N 3 Powder, HfO 2 Powder and TiO 2 The powder is prepared by traditional ceramic technology according to the ratio; when preparing ceramic targets, the sintering temperature is lower than the phase formation temperature of each system by 100 °C.

[0055] Step 2, put the substrate, vacuum: Nb:SrTiO 3 The substrate is placed on the heating platform, and the vacuum degree in the deposition chamber is less than 1×10 by using a mechanical pump and a molecular pump. -5 mbar.

[0056] Step 3. Ventilate and heat up: inject 200 mbar of argon-oxygen mixed gas with a volume ratio of 1 / 1, then raise the temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Breakdown field strength | aaaaa | aaaaa |

| Energy storage density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com