Metal self-supporting electrode, preparation method and application

A self-supporting electrode, metal technology, applied in electrodes, electrode coatings, non-precious metal oxide coatings, etc., can solve the problems of low electrocatalyst activity, low product selectivity, high application cost, and achieve good electrocatalytic redox The effect of high reactivity, high product selectivity and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

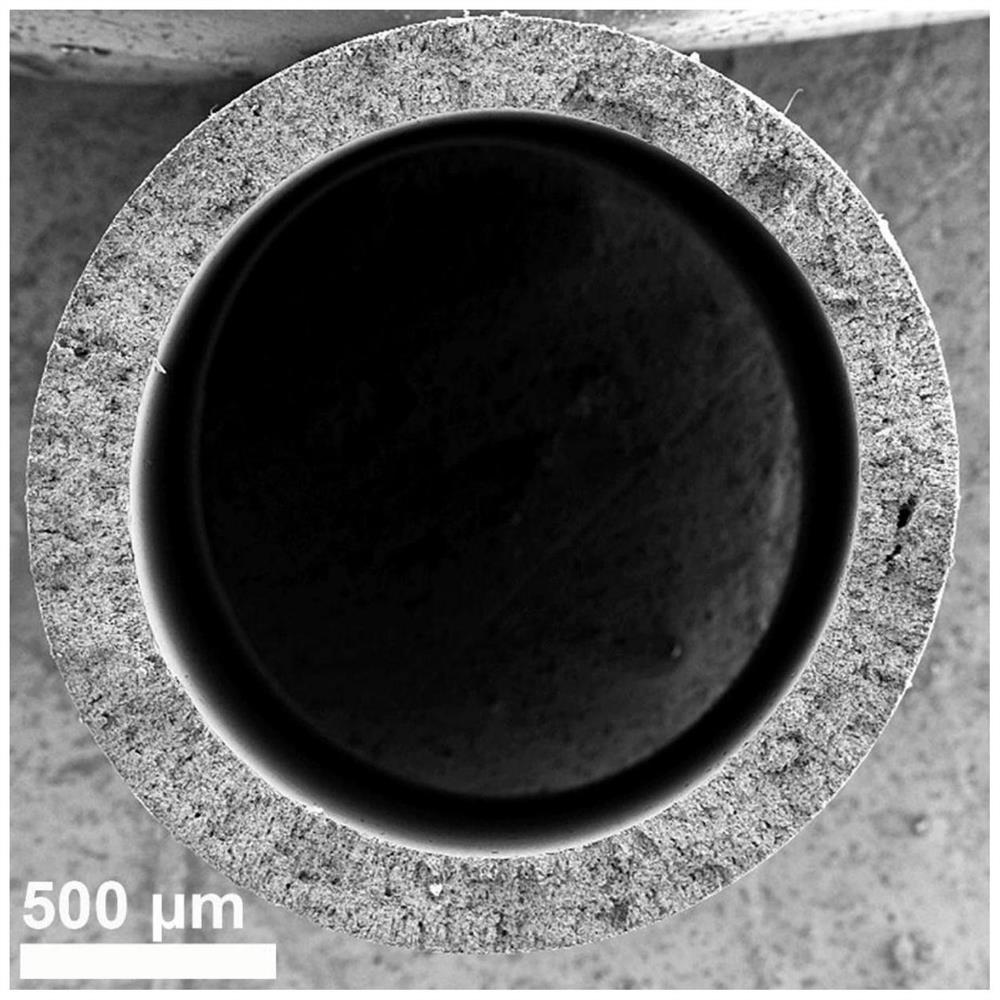

[0043] The preparation method of the metal self-supporting electrode in the present invention is simple, and the preparation cost is low. The shape of the prepared metal self-supporting electrode is a hollow fiber tube, the thickness of the tube wall is between 100nm and 300 μm, and the inner surface and the outer surface of the tube are porous. , the pore size is between 10nm and 10μm, and the raw metal powder, metal oxide powder or alloy powder used in the metal self-supporting electrode presents a partially sintered and fused state; the metal self-supporting electrode prepared in the present invention has good Electrocatalytic redox reaction activity, high product selectivity, high reproducibility and good stability; using low-grade renewable energy as an energy source, metal self-supporting electrodes can achieve directional conversion of small energy molecules at room temperature, And it is easy to apply on an industrial scale, not only for electrocatalytic CO 2 , N 2 、H...

Embodiment 1

[0101] This embodiment provides a metal self-supporting electrode, and its preparation method specifically includes the following steps:

[0102] S1. Mix spherical copper powder with a particle size of 50nm, NMP and PEI in proportions of 40wt%, 48wt%, and 12wt%, respectively, and ball mill for 12h at a rotating speed of 300r / min to obtain a uniform slurry;

[0103] S2. Degas the slurry in a vacuum drying oven for 12 hours. Driven by a syringe pump, the slurry is sprayed out through the spinneret at 7mL / min, then enters the coagulation solution through the air layer, and casts to form a hollow fiber tubular software. Wherein, the core liquid of spinneret is ultrapure water, and the flow rate of core liquid is 15mL / min, and coagulation liquid is tap water, and the air distance between spinneret and coagulation liquid liquid level is 1cm;

[0104] S3. Rinse the hollow fiber tubular soft body continuously with flowing tap water to remove the organic solvent, straighten and fix the...

Embodiment 2

[0109] This embodiment provides a metal self-supporting electrode. The difference between its preparation method and Embodiment 1 is that the raw material in step S1 is spherical copper powder with a particle size of 100 nm, NMP and PEI according to 43wt%, 46wt%, and 11wt%, respectively. The ratio is mixed; other steps and methods are the same as in Example 1, and will not be repeated here, and finally a copper self-supporting electrode with a porous hollow fiber tubular structure is prepared.

[0110]This embodiment also provides an application of a copper self-supporting electrode, which uses a constant potential method to reduce CO 2 , the applied voltage is -0.9Vvs.RHE, the reaction time is 1h, and the electrolyte is 0.5M KHCO 3 aqueous solution to obtain hydrogen, carbon monoxide and formic acid products, wherein the faradaic current efficiency of formic acid reaches 84.6%, which has good selectivity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Tube wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com