Diamond saw blade for rock plate cutting and manufacturing method thereof

A technology of diamond saw blades and production methods, which is applied in the field of powder metallurgy, can solve the problems of slow cutting speed, poor cutting edge chipping, and high cost of saw blades, and achieve the effects of lowering the melting point, neat edge chipping, and improving comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

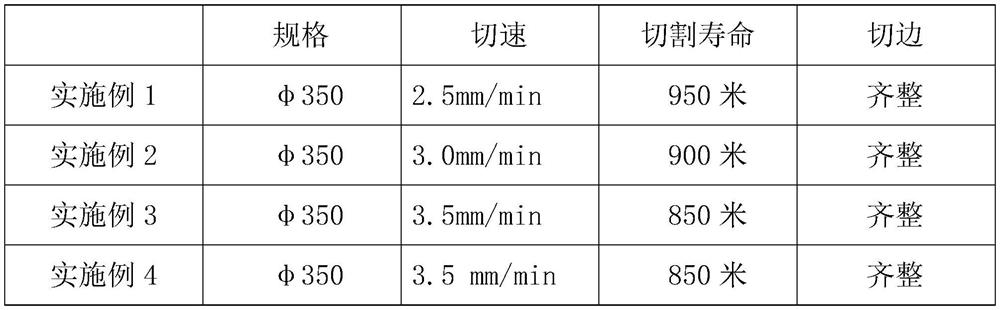

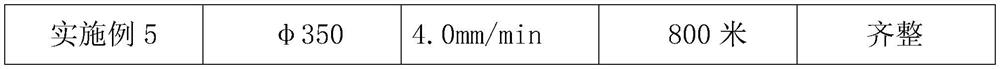

Embodiment 1

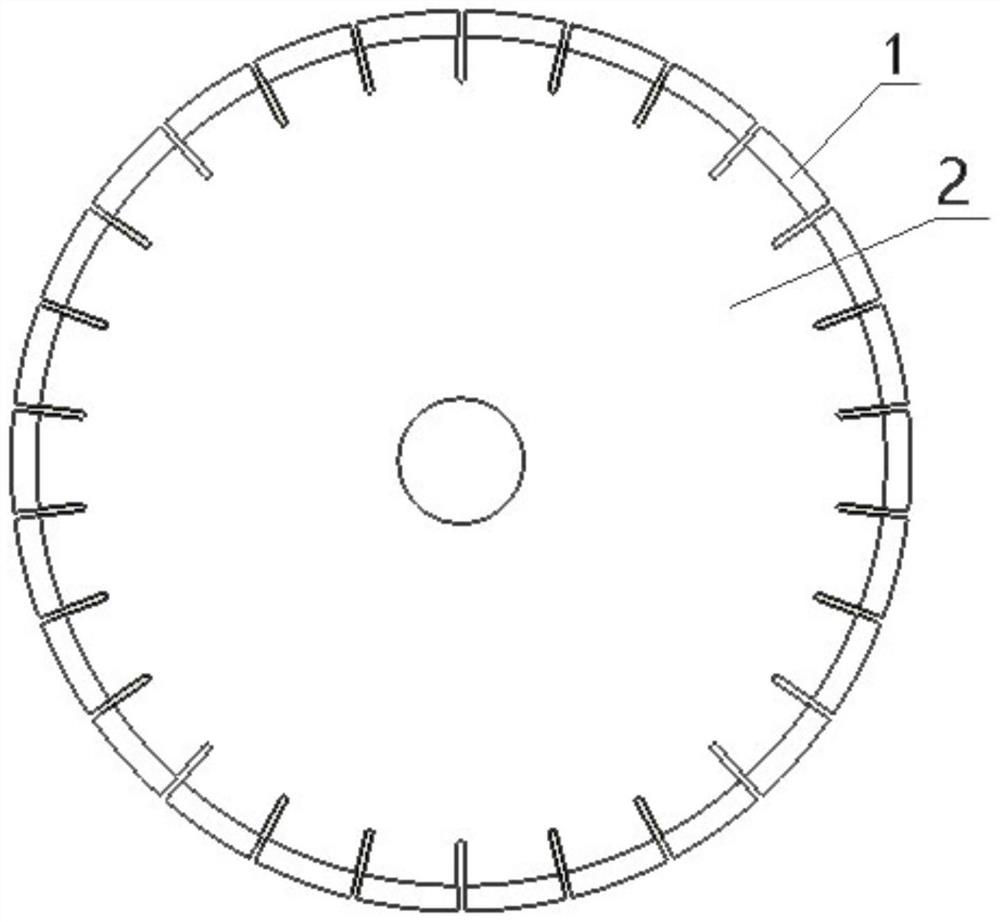

[0030] see figure 1 , a diamond saw blade for cutting rock slabs and a manufacturing method thereof, comprising a cutter head 1 and a base body 2, the cutter head 1 includes raw materials in the following weight percentages: 20-40 parts of copper powder, 10-25 parts of tin powder , 10-30 parts of iron powder, 5-20 parts of superfine cobalt powder, 5-15 parts of nickel powder, 10-15 parts of zinc powder, 1-3 parts of graphite, and the proportion of diamond volume fraction is 10 -30% (by 400%), the diamond particle size is 60-180 orders, specifically comprising the following steps:

[0031] (1) Ingredients: Weigh 40 parts of copper powder, 10 parts of tin powder, 15 parts of iron powder, 5 parts of superfine cobalt powder, 14 parts of nickel powder, 15 parts of zinc powder, and 1 part of graphite, of which the volume fraction of diamond is 10%, the diamond particle size is 60 mesh, and the above raw materials are mixed to obtain alloy matrix powder;

[0032] (2) Mixing: Put th...

Embodiment 2

[0039] The diamond saw blade of this embodiment and its manufacturing method are the same as in Example 1, the difference being that 20 parts of copper powder, 12 parts of tin powder, 15 parts of iron powder, 20 parts of superfine cobalt powder, 15 parts of nickel powder, and 15 parts of zinc powder are weighed. 15 parts and 3 parts of graphite, wherein the volume fraction of diamond is 30%, and the particle size of diamond is 180 mesh. The above raw materials are mixed to obtain alloy matrix powder.

Embodiment 3

[0041] The diamond saw blade of this embodiment and its production method are the same as in Example 1, the difference being that 20 parts of copper powder, 25 parts of tin powder, 30 parts of iron powder, 5 parts of superfine cobalt powder, 5 parts of nickel powder, and zinc powder are weighed. 14 parts, 1 part of graphite, wherein the diamond volume fraction is 15%, and the diamond particle size is 80 meshes. The above raw materials are mixed to obtain alloy matrix powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com