Glass substrate cleaning method and cleaning equipment

A glass substrate, preliminary cleaning technology, applied in the direction of cleaning methods and utensils, cleaning methods using liquids, cleaning methods using tools, etc., can solve the problems of simple glass substrate cleaning process, low glass substrate collar frequency, and inability to guarantee the surface of the glass substrate Cleanliness and other issues to achieve the effect of improving the cleaning effect, preventing the adsorption of impurities, and avoiding scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

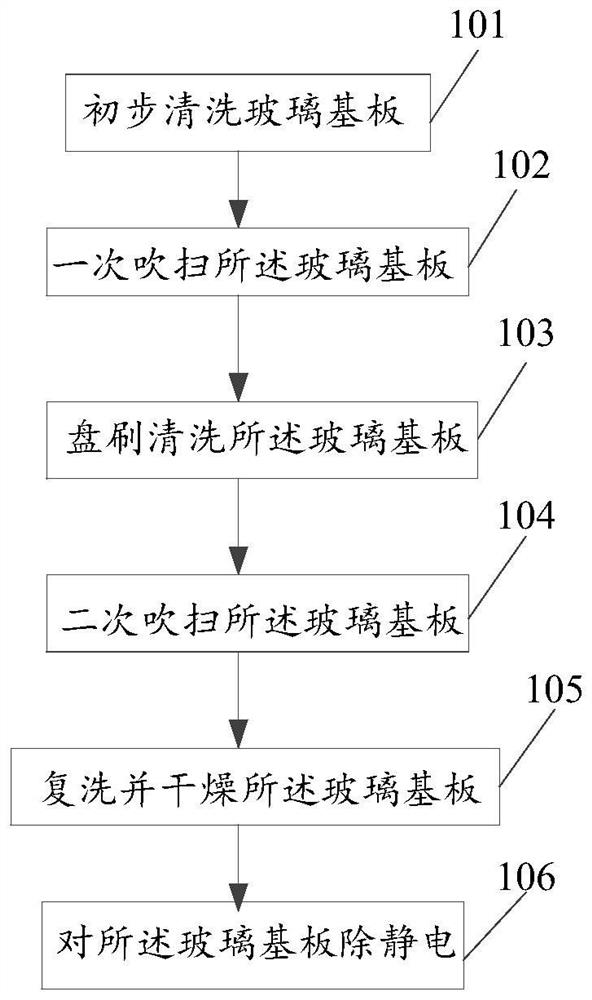

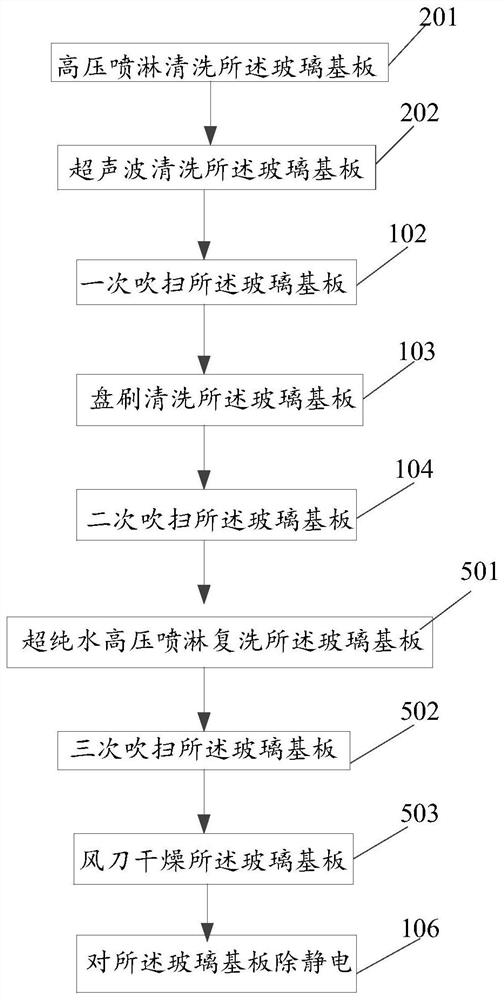

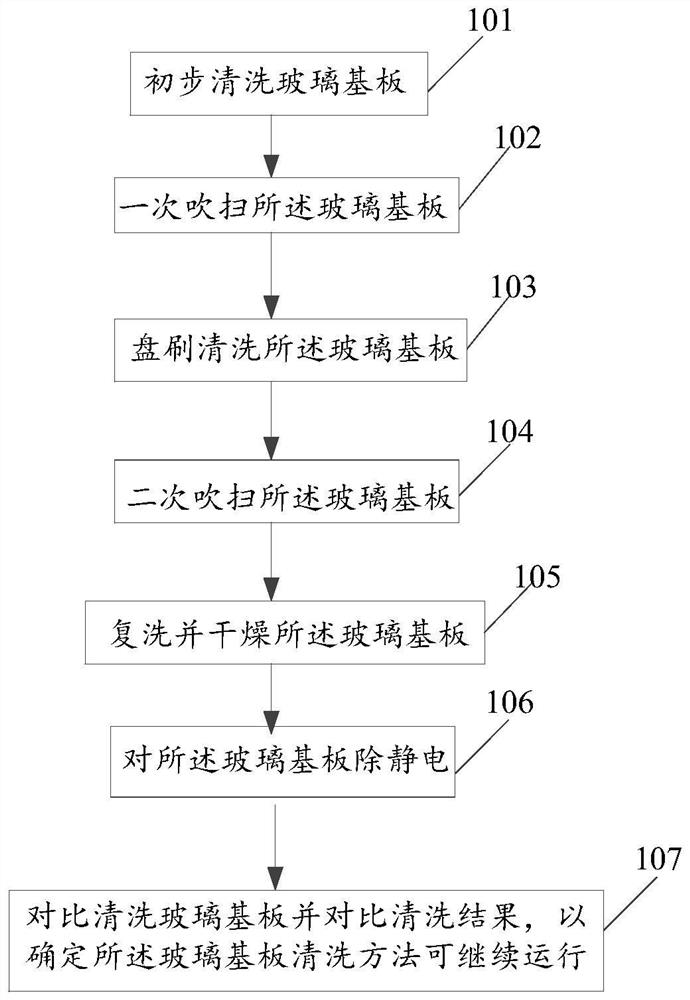

[0053] Reference attached figure 1, the glass substrate cleaning method provided in the embodiment of the present application, the cleaning environment where it is located requires that the ambient pressure is 10pa-15pa higher than the atmospheric pressure, the cleanliness is 2000-5000, and the cleanliness is in accordance with the "Code for Design of Clean Workshops" GB50073-2001 standard; The glass substrate cleaning method that embodiment provides comprises the following steps:

[0054] 101. Preliminary cleaning of the glass substrate;

[0055] Specifically, the glass substrate enters the cleaning process after the edging process. In this step, the glass substrate is preliminarily cleaned by washing with water, so that the grinding powder brought by the edging process and larger particles or impurities on the surface of the glass substrate can be removed;

[0056] Among them, the method of preliminary cleaning can be one or more of methods such as high-pressure spraying an...

Embodiment 2

[0115] Reference attached Figure 4 , the embodiment of the present application provides a cleaning device 1, which includes a controller (not shown in the figure), a conveying device 2, and preliminary cleaning units sequentially arranged on the conveying device 2 along the conveying direction of the conveying device 2 3. The first purging unit 4, the disc brush cleaning unit 5, the second purging unit 6, the rewashing and drying unit 7 and the ion fan unit 8;

[0116] The controller (not shown in the figure) is signal-connected with the conveying device 2 to control the conveying device 2 to start / stop conveying the glass substrate;

[0117] The controller (not shown in the figure) is connected with the preliminary cleaning unit 3, the first purging unit 4, the dish brush cleaning unit 5, the second purging unit 6, the rewashing and drying Unit 7 and the ion fan unit 8 are signal connected to control the preliminary cleaning unit 3, the first purging unit 4, the disc brush ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com