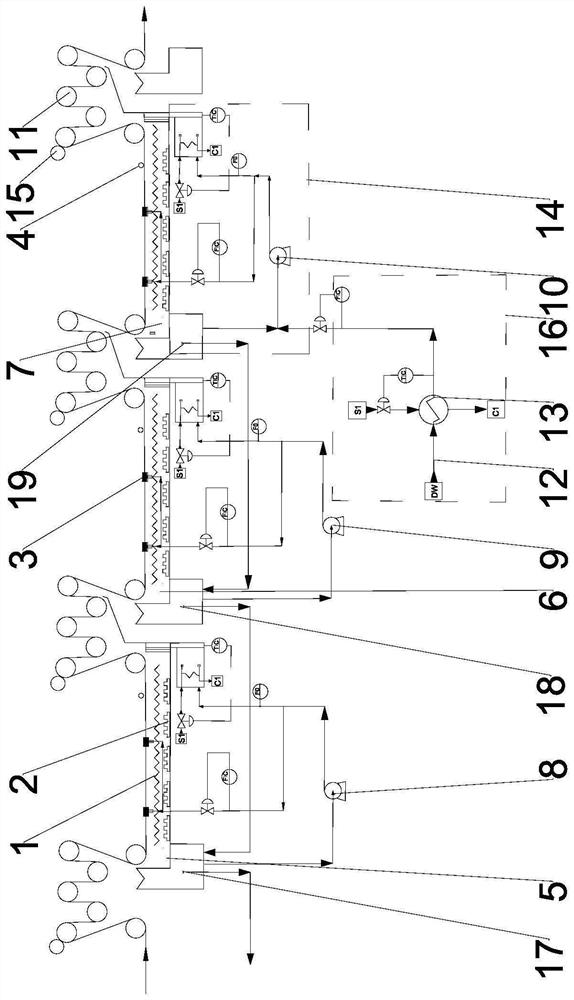

Three-stage boiling water drafting device and method for large-tow carbon fiber precursor production

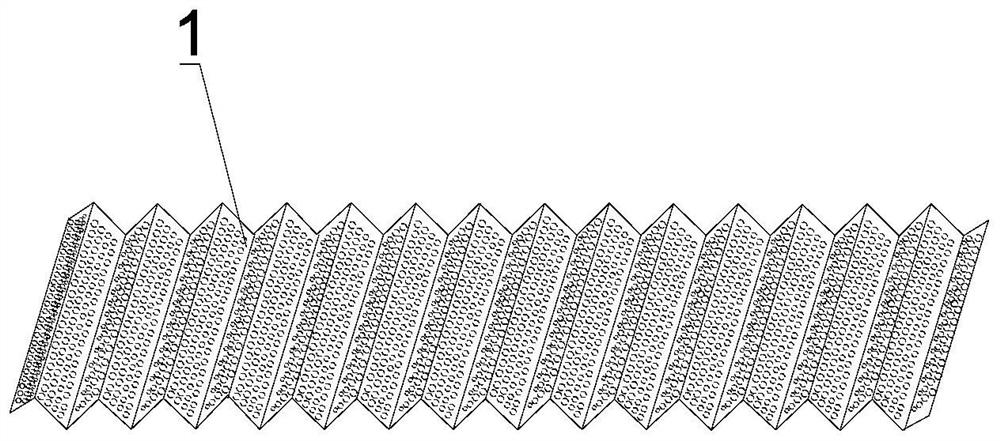

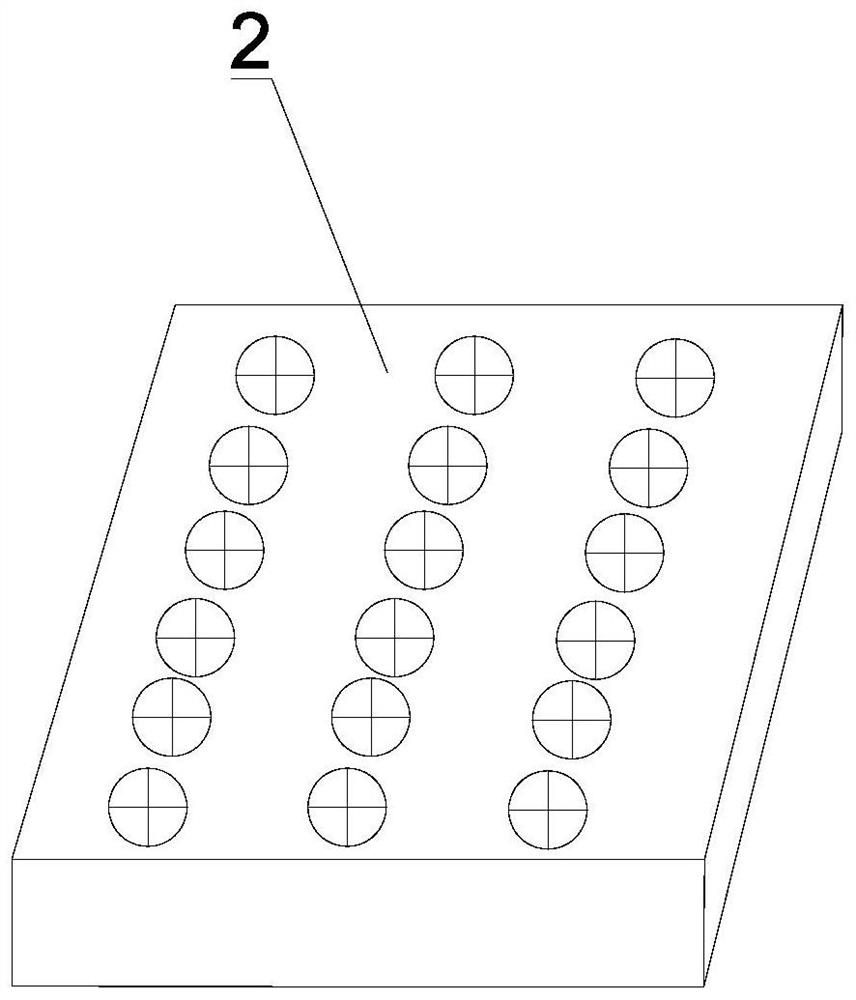

A carbon fiber raw fiber and drafting device technology, which is applied in the directions of filament generation, drawing spinning, and complete sets of equipment for producing artificial threads, etc. , to achieve the effect of improving physical and mechanical properties, easy three-level effective drafting, and ensuring production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Use a kind of large tow carbon fiber precursor of the present invention to produce the method for three-stage boiling water drawing device, control the temperature of the third stage boiling water drawing tank 7 at 99 ℃, the drafting ratio of the third stage boiling water drawing tank is 1.85 times; control the temperature of the second-stage boiling water drawing tank 7 at 97°C, and the draw ratio of the second-stage boiling water drawing tank is 1.85 times; control the temperature of the first-stage boiling water drawing tank 7 at 94°C, The drafting ratio of the first-stage boiling water drawing tank is 1.85 times; the calculation shows that the tow achieves a total of 6.33 times of drafting in the third-stage boiling water drawing tank. Observation found that the tow did not produce a large number of broken filaments and hairy filaments, achieved the preset goal, and obtained large tow carbon fiber precursors with higher physical and mechanical properties. Finally, t...

Embodiment 2

[0044] Use a kind of large tow carbon fiber precursor of the present invention to produce the method for three-stage boiling water drawing device, control the temperature of the third stage boiling water drawing tank 7 at 98 ℃, the drafting ratio of the third stage boiling water drawing tank is 1.8 times; control the temperature of the second-stage boiling water drawing tank 7 at 96°C, and the draw ratio of the second-stage boiling water drawing tank is 1.6 times; control the temperature of the first-stage boiling water drawing tank 7 at 93°C, The drafting ratio of the first-stage boiling water drawing tank is 1.5 times; the calculation shows that the tow achieves a total of 4.32 times of drafting in the third-stage boiling water drawing tank. Observation found that the tow did not produce a large number of broken filaments and wool filaments, and achieved the preset goal. Finally, the residual amount of dimethyl sulfoxide in the tow after drawing in third-stage boiling water ...

Embodiment 3

[0046] Use a kind of large tow carbon fiber precursor of the present invention to produce the method for three-stage boiling water drawing device, control the temperature of the third stage boiling water drawing tank 7 at 97 ℃, the drafting ratio of the third stage boiling water drawing tank is 1.6 times; control the temperature of the second-stage boiling water drawing tank 7 at 95°C, and the draw ratio of the second-stage boiling water drawing tank is 1.6 times; control the temperature of the first-stage boiling water drawing tank 7 at 92°C, The drafting ratio of the first-stage boiling water drawing tank is 1.6 times; the calculation shows that the tow achieves a total of 4.1 times of drafting in the third-stage boiling water drawing tank. Observation found that the tow did not produce a large number of broken filaments and wool filaments, and achieved the preset goal. Finally, the residual amount of dimethyl sulfoxide in the tow after three-stage boiling water drawing is d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com