Preparation method of temperature measuring seat for superconducting feeder system

A superconducting feeder, holding time technology, applied in manufacturing tools, welding equipment, metal processing equipment, etc., can solve problems such as performance differences, achieve simple structure, realize capillary and wetting effects, and reliable connection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

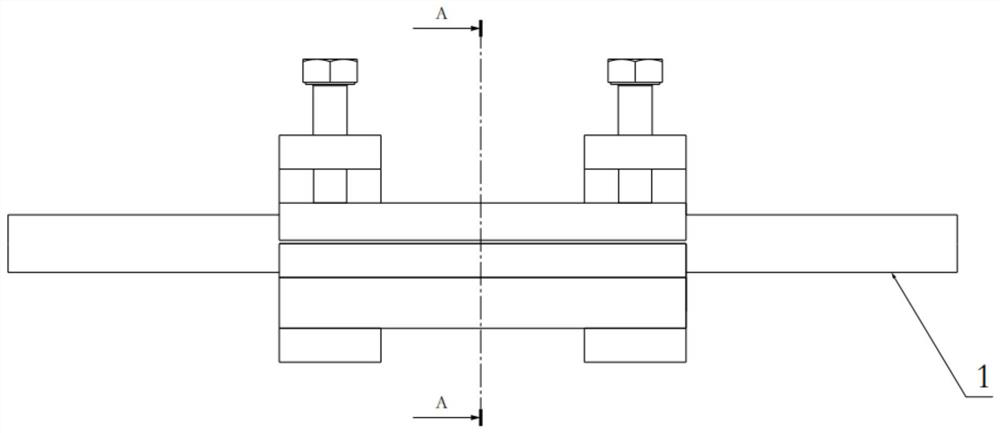

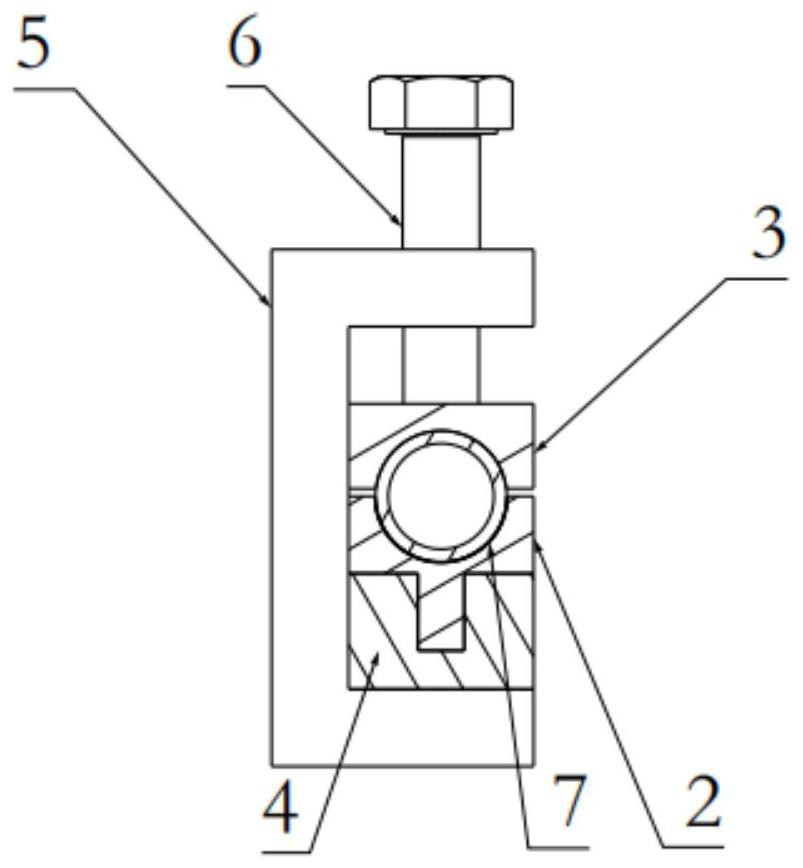

[0038] Please refer to Figure 1-2, the present embodiment provides a superconducting feeder system with a temperature measuring seat preparation method, the temperature measuring seat comprises a mutually welded base 2 and a round tube 1, the base 2 material is C10100 oxygen-free copper, which is welded with the round tube 1 side is curved, C10100 oxygen-free copper cold, hot processing performance are excellent, good malleability. Round tube 1 material is 316L stainless steel; 316L stainless steel has excellent corrosion resistance, high temperature resistance and creep resistance, wherein the present invention employs a vacuum brazing process to weld 316L round tube 1 and C10100 base 2, comprising the following steps:

[0039] Brazing material selection: The implementation of brazing material 7 selects Ag72Cu28 brazing material, melting temperature of 779 °C, not only has excellent process performance, such as suitable melting point, good wetting, strong caulking ability, etc.,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com