Vacuum brazing method for connecting Ti-6Al-4V and CuZrCr

A technology of ti-6al-4v, brazing method, applied in the direction of welding equipment, welding equipment, non-electric welding equipment, etc., can solve the problems of difficult connection, large difference in physical properties, etc., and achieve convenient use, ensure contact, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

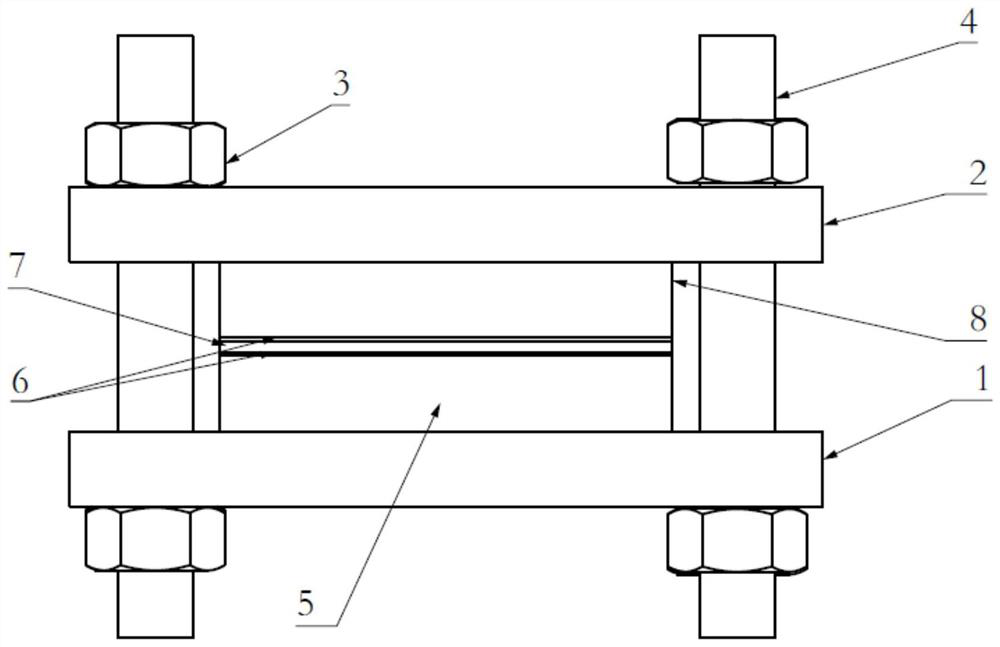

[0038] Please refer to figure 1 This embodiment provides a vacuum brazing method for Ti-6Al-4V and CuzrCr connection:

[0039] Solder selection: The solder 6 in this example is selected from the group consisting of AG68Cu28Ti4 foil solder, and the melting temperature is 800 to 820 ° C;

[0040] In this example, 0.5 ~ 1 mm thick Tu1 oxygen-free copper 7 is used as a heterogeneous transition metal of Ti-6Al-4V and CuZRCR;

[0041] The Ti-6Al-4V matrix material 5 is pretreated, including the sequential removal, rinsing, and dry dry, specifically comprising immersing the Ti-6Al-4V matrix material 5 into 90 ° C 40 g / L, carbonated Sodium 30g / L, trisodium phosphate 30g / L, sodium silicate 5g / L and water mixed ratio, after 5 minutes, Ti-6Al-4V matrix material 5 is 60 ml / L according to nitric acid 50 ml / L, hydrofluoric acid 5 ml / L and water mixed ratio of water were soaked in 5 minutes, rinsed with flowing hot water, and dried with dry oil-free compressed air;

[0042] The TU1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com