Rare earth magnesium alloy metallographic corrosive agent and metallographic sample preparation method thereof

A metallographic sample, rare earth magnesium technology, applied in the preparation of test samples, etc., can solve the problems of excessive corrosion of rare earth magnesium alloy samples, poor corrosion effect of rare earth magnesium alloys, and affecting the quality of metallographic micrographs, etc., to achieve Prevent the metallographic sample from being scrapped, reduce the time for repeated sample copying, and reduce the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] In another aspect of the present invention, the present invention provides a method for preparing a rare earth magnesium alloy metallographic sample using the rare earth magnesium alloy metallographic etchant of the present invention, comprising:

[0037] (1) Preparation: Take a sample, cut the sample into thin slices of appropriate size, put the surface to be observed for metallography facing outward, and paste the reverse side on the balance grinding table; samples with irregular shapes can be hot-mounted with a mounting machine.

[0038] (2) Grinding: Use a grinding and polishing machine to polish the sample. Due to the low hardness of the rare earth magnesium alloy, use water sandpaper with a particle size of 800 to polish the surface oxide layer, and then grind with water sandpaper with a particle size of 1500, 3000, and 5000 in turn. After each sandpaper is replaced, the sanding direction is rotated 90 degrees, and after the scratches in the sanding direction of th...

Embodiment 1

[0048] The composition of the rare earth magnesium alloy metallographic etchant of this embodiment is as follows: 1.5 ml of nitric acid, 0.5 ml of glacial acetic acid, 1.5 g of oxalic acid, and 98 ml of deionized water.

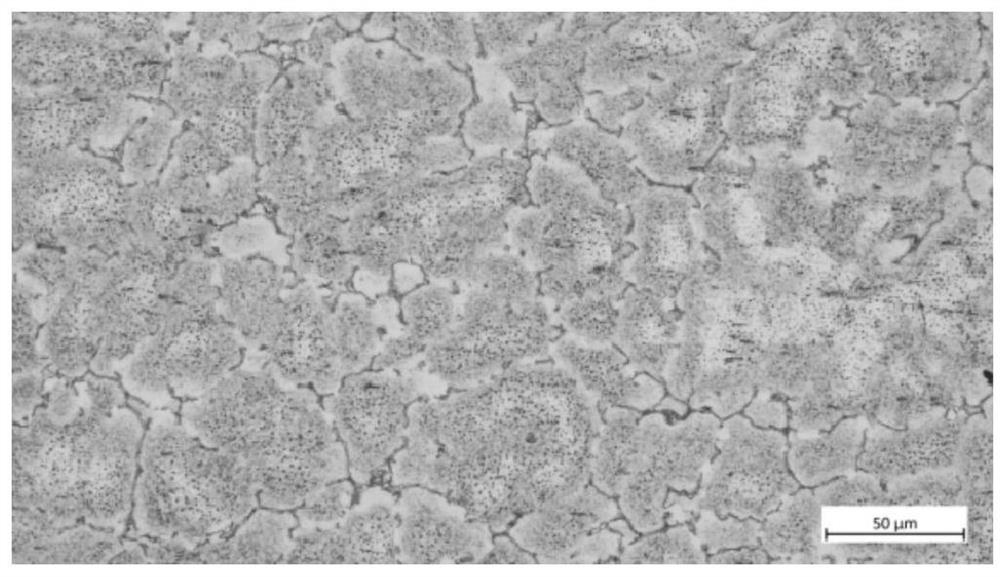

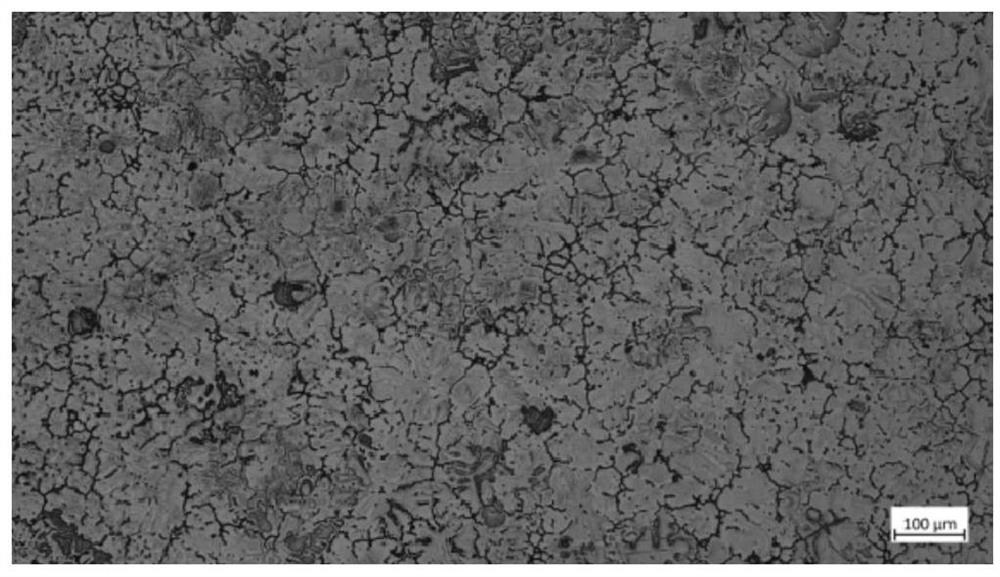

[0049] Using the metallographic etchant mentioned above, the as-cast and extruded ZE62 rare earth magnesium alloy samples were respectively prepared, and the corrosion time was 12s. The obtained ZE62 magnesium alloy metallographic samples are shown in Figure 2(a) and Figure 2(b). It can be seen that both samples have clear grain outlines, but at the same time, the surface is somewhat oxidized and yellowed, and the grain boundaries are precipitated There are also many things.

Embodiment 2

[0051] The composition of the rare earth magnesium alloy metallographic etchant in this embodiment is as follows: 1 ml of nitric acid, 1 ml of glacial acetic acid, 1 g of oxalic acid, and 98 ml of deionized water.

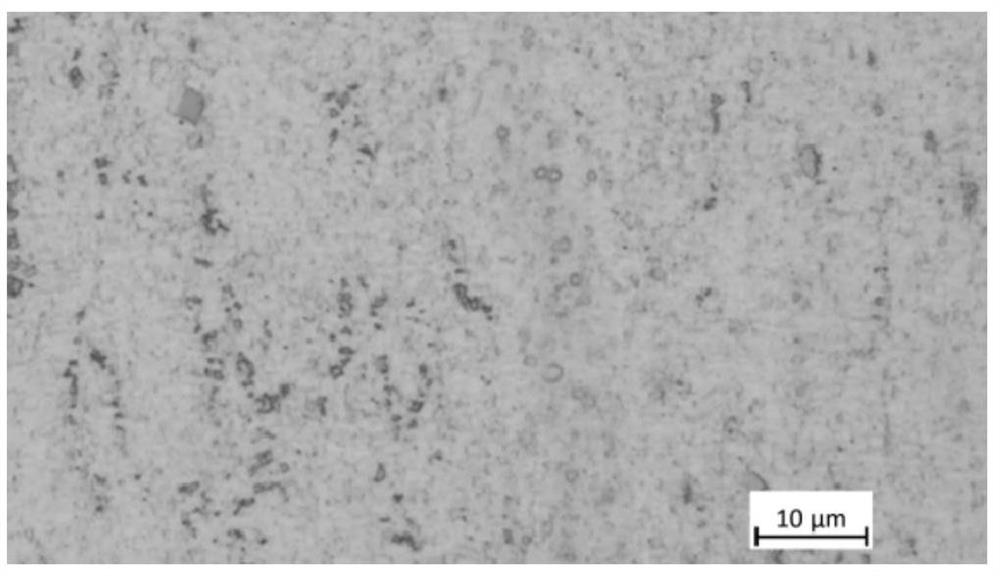

[0052] Using the metallographic etchant mentioned above, ZE62 rare earth magnesium alloy samples in cast state and extruded state were respectively prepared, and the corrosion time was 15s. The obtained ZE62 magnesium alloy metallographic samples are shown in Figure 3(a) and Figure 3(b). It can be seen that the metallographic structure of the two samples is obvious, the crystal plane is clean, the grain boundary is clear, and the corrosion effect is good .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com