Method for preparing super-hydrophobic porous material based on double-emulsion template

A technology of porous material and emulsion template, applied in separation methods, chemical instruments and methods, liquid separation, etc., to achieve the effect of simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

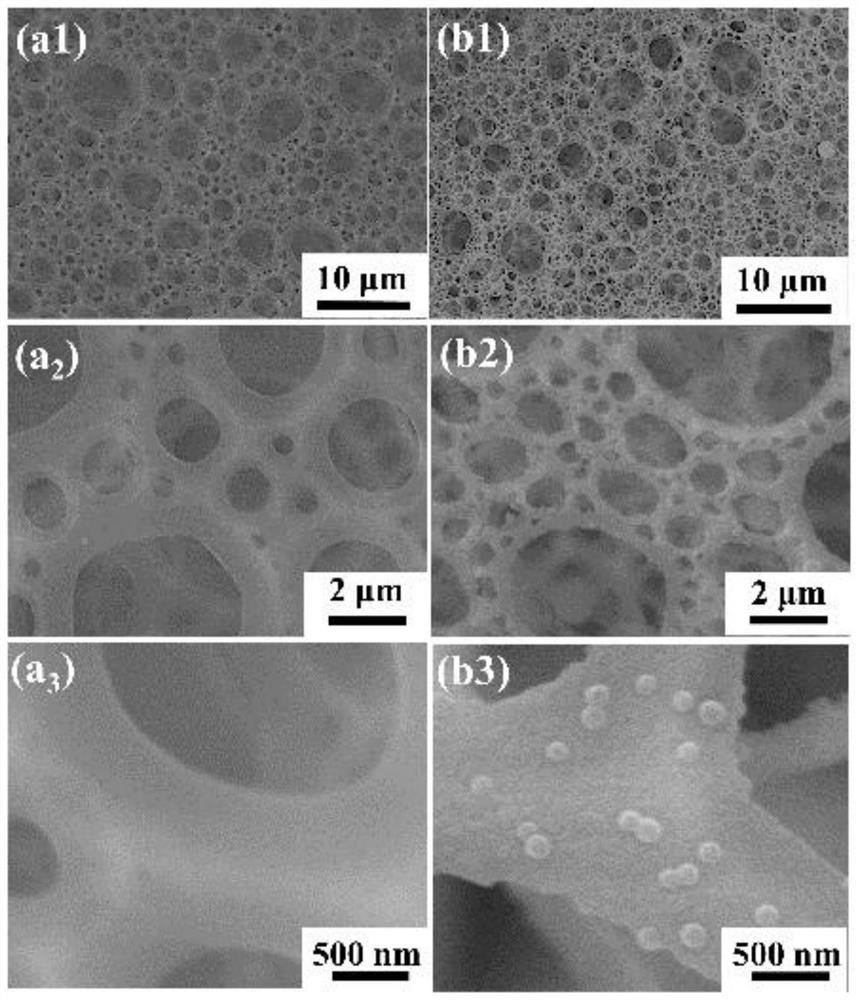

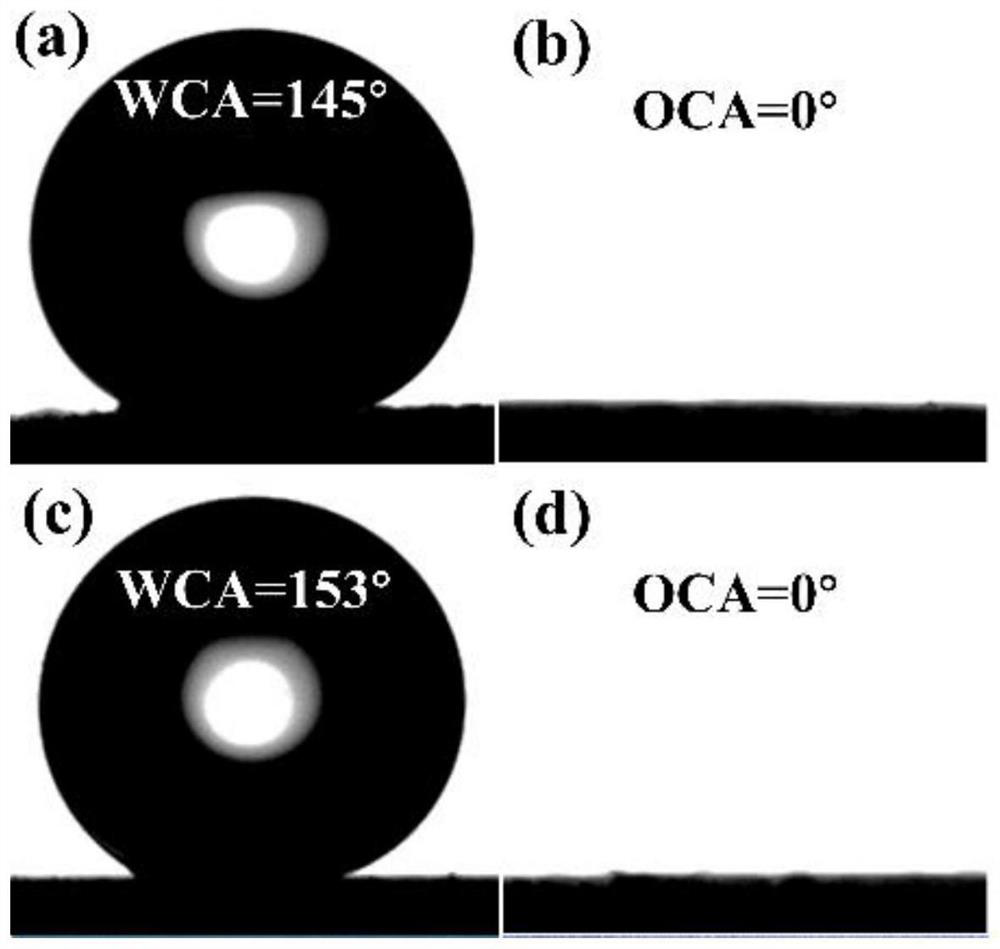

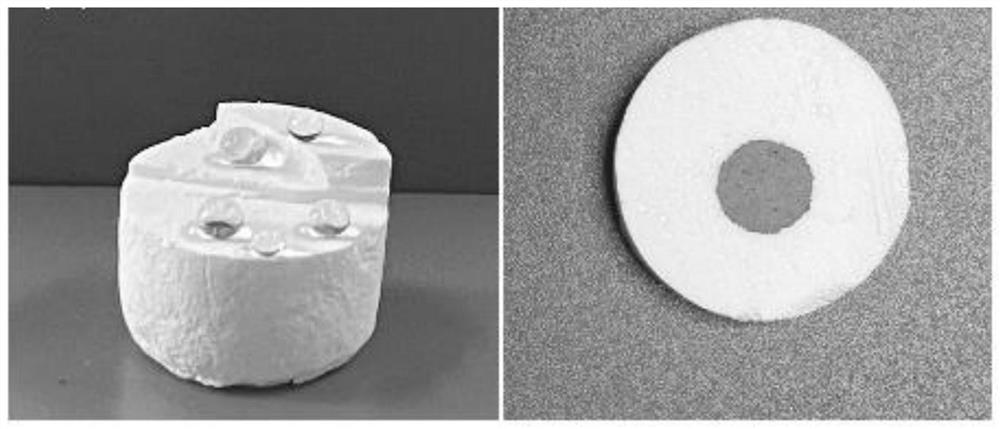

[0029] A method for preparing superhydrophobic porous materials based on double emulsion templates: (1) 2 parts by weight of γ-aminopropyltriethoxysilane, 0.4 parts by weight of sodium dodecylsulfonate and 2 parts by weight of initiator persulfuric acid Sodium was dispersed in 2000 parts by weight of deionized water to obtain emulsion template A containing siloxane coupling agent, hydrophilic emulsifier and initiator. (2) Add 2004.4 parts by weight of emulsion template A to 30 parts by weight of styrene, 15 parts by weight of crosslinking agent A divinylbenzene, 5 parts by weight of crosslinking agent B ethylene glycol dimethacrylate and 10 parts by weight of hydrophilic In the high internal phase emulsion template B composed of oily emulsifier Span80, emulsify with mechanical stirring at 200r / min for 10min to obtain a double emulsion template prepolymerization system composed of emulsion template A and high internal phase emulsion template B. (3) The double-emulsion template ...

Embodiment 2

[0031] A method for preparing superhydrophobic porous materials based on double emulsion templates: (1) 10 parts by weight of γ-aminopropyltriethoxysilane, 1 part by weight of cetyltrimethylammonium bromide and 2 parts by weight of initiator Agent ammonium persulfate was dispersed in 1000 parts by weight of deionized water to obtain emulsion template A containing siloxane coupling agent, hydrophilic emulsifier and initiator. (2) Add 1013 parts by weight of emulsion template A to 30 parts by weight of styrene, 10 parts by weight of crosslinking agent AN, N-methylenebisacrylamide, 10 parts by weight of crosslinking agent B trimethylolpropane triacrylate In the high internal phase emulsion template B composed of 15 parts by weight lipophilic emulsifier MOA-3, at 800r / min mechanical stirring and emulsification for 20min, a double emulsion template prepolymerization system consisting of emulsion template A and high internal phase emulsion template B was obtained . (3) The double-e...

Embodiment 3

[0033] A method for preparing superhydrophobic porous materials based on double emulsion templates: (1) 1 weight part of γ-glycidyl etheroxypropyltrimethoxysilane, 0.2 weight part of alkyl glucoside and 1 weight part of initiator cumene Hydrogen peroxide was dispersed in 2000 parts by weight of deionized water to obtain emulsion template A containing siloxane coupling agent, hydrophilic emulsifier and initiator. (2) Add 2002.2 parts by weight of emulsion template A to 20 parts by weight of styrene, 20 parts by weight of crosslinking agent A ethylene glycol dimethacrylate, 10 parts by weight of crosslinking agent B dipentaerythritol pentaacrylate and 20 parts by weight of In the high internal phase emulsion template B composed of lipophilic emulsifier oleic acid ester, at 100r / min mechanical stirring emulsification 60min, obtain the double emulsion template prepolymerization system that is made up of emulsion template A and high internal phase emulsion template B; (3) The doubl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com