Soil activation type microbial fertilizer and preparation method thereof

A technology for microbial fertilizer and soil activation, applied in the field of soil activated microbial fertilizer and its preparation, can solve the problems of soil microenvironment, biological activity and effective nutrient destruction, unfavorable agricultural sustainable development, secondary soil pollution, etc. Achieve the effect of achieving sustainable development, promoting recycling, and protecting the ecological environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

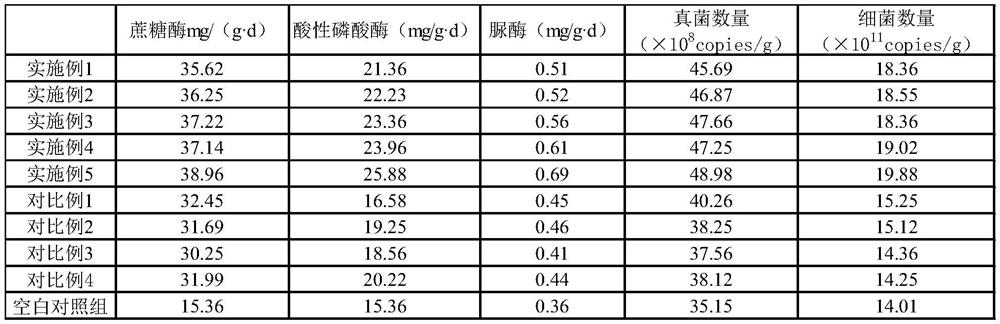

Examples

Embodiment 1

[0033] A soil-activated microbial fertilizer, prepared from the following raw materials in parts by weight: 100 parts of humic acid, 80 parts of furfural residue, 80 parts of soybean meal, 20 parts of biochar, 10 parts of urea, 5 parts of monoammonium phosphate, and 10 parts of potassium sulfate , 5 parts of potassium pyrophosphate, 1 part of medium and trace elements, 1 part of compound microbial agent, 5 parts of water-retaining gel, and 0.5 part of accelerator.

[0034] The medium and trace elements are obtained by mixing borax, manganese sulfate, copper sulfate and sodium molybdate in a mass ratio of 5:1:1.5:0.5.

[0035] The composite microbial bacterial agent is prepared from Bacillus subtilis, high-efficiency phosphate solubilizing bacteria, Bacillus megaterium and Bacillus cereus in a mass ratio of 1:1:1.5:1.5.

[0036]The preparation method of the composite microbial bacterial agent is as follows: after activating Bacillus subtilis, high-efficiency phosphate solubiliz...

Embodiment 2

[0050] A soil-activated microbial fertilizer, prepared from the following raw materials in parts by weight: 105 parts of humic acid, 90 parts of furfural residue, 90 parts of soybean meal, 30 parts of biochar, 13 parts of urea, 6 parts of monoammonium phosphate, and 15 parts of potassium sulfate , 6 parts of potassium pyrophosphate, 1.5 parts of medium and trace elements, 1.5 parts of compound microbial agent, 6 parts of water-retaining gel, and 1 part of accelerator.

[0051] The medium and trace elements are obtained by mixing borax, manganese sulfate, copper sulfate and sodium molybdate in a mass ratio of 5:2:2:0.8.

[0052] The composite microbial bacterial agent is prepared from Bacillus subtilis, high-efficiency phosphate solubilizing bacteria, Bacillus megaterium and Bacillus cereus in a mass ratio of 1:1.5:2:2.5.

[0053] The preparation method of the composite microbial bacterial agent is as follows: after activating Bacillus subtilis, high-efficiency phosphate solubi...

Embodiment 3

[0067] A soil-activated microbial fertilizer, prepared from the following raw materials in parts by weight: 110 parts of humic acid, 100 parts of furfural residue, 100 parts of soybean meal, 30 parts of biochar, 15 parts of urea, 7 parts of monoammonium phosphate, and 15 parts of potassium sulfate , 7 parts of potassium pyrophosphate, 1.5 parts of medium and trace elements, 1.8 parts of compound microbial agent, 7 parts of water-retaining gel, and 1 part of accelerator.

[0068] The medium and trace elements are obtained by mixing borax, manganese sulfate, copper sulfate and sodium molybdate in a mass ratio of 5:3:2.5:1.

[0069] The composite microbial bacterial agent is prepared from Bacillus subtilis, high-efficiency phosphate solubilizing bacteria, Bacillus megaterium and Bacillus cereus in a mass ratio of 1:1.5:2:2.5.

[0070] The preparation method of the composite microbial bacterial agent is as follows: after activating Bacillus subtilis, high-efficiency phosphate solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com