Preparation method of high-speed steel working roll for finish rolling of hot rolled strip

A technology of high-speed steel and work rolls, applied in the field of materials, can solve the problems of limiting the production capacity of hot-rolled lines and the use of finishing-rolled high-speed steel, and achieve the effects of prolonging the machine cycle, increasing the carbide content, and good accident resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

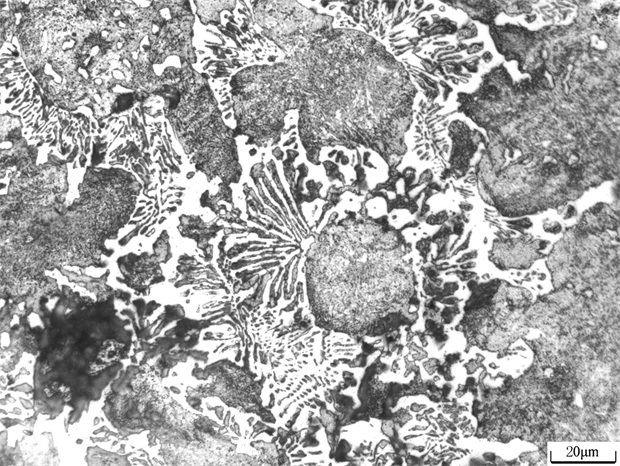

[0024] A method for preparing hot-rolled strip finishing high-speed steel work rolls, comprising the steps of:

[0025] Step A, smelting molten iron to meet the corresponding composition requirements, the melting temperature of the outer layer of molten steel is 1400-1700°C, and the melting temperature of the core molten steel at 1300-1600°C meets the design composition requirements before it can be released from the furnace for pouring;

[0026] Step B. After the smelting composition reaches the standard, the outer layer and the core molten iron are heated to a temperature of 1500-1800°C and released from the furnace, and poured when the temperature drops to 1200-1500°C. When pouring, the outer layer adopts the method of adding inoculant with the flow, and the core molten iron adopts the method of adding nodulizer inoculant at the bottom of the bag. The top of the nodulizer is covered with a 10-20mm thick steel plate, and steel scrap is used around the steel plate. Crumb cove...

Embodiment 1

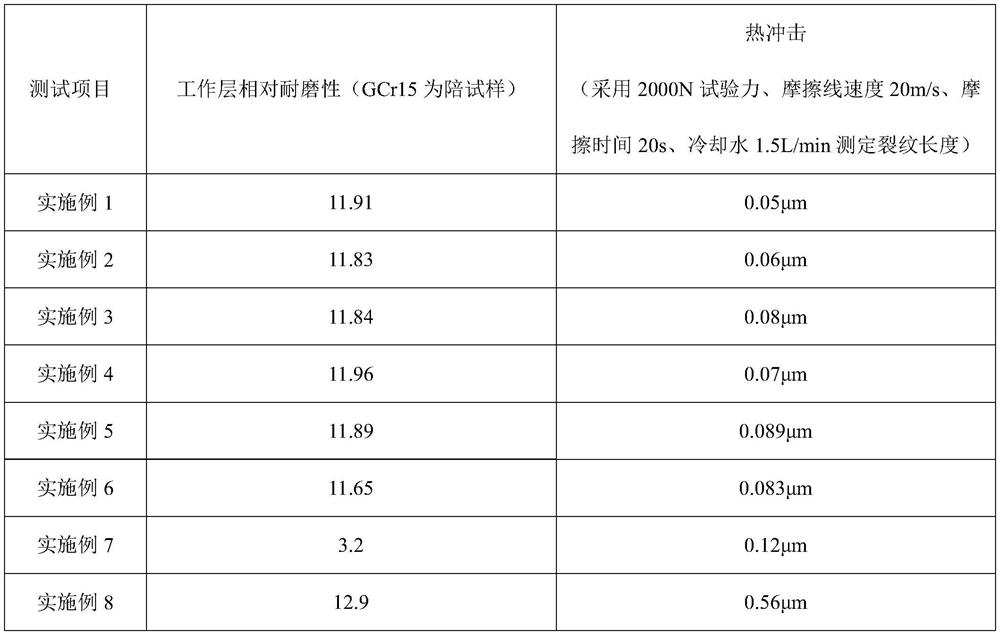

[0038] Using scrap steel shavings, forged steel heads, ferromolybdenum, ferrovanadium, and electrode powder as raw materials, it is smelted in an intermediate frequency furnace to reach the design composition range of high-speed steel: outer layer molten iron C1.98%, Si1.56%, Mn0.9%, P0.06%, S0.07%, Cr3.56%, Ni2.51%, Mo0.85%, V2.39%, W0.96%, the balance is Fe; core molten iron C2.93%, Si1.32 %, Mn0.75%, P0.06%, S0.08%, Cr0.03%, Ni0.23%, Mo0.25%, W+V+Nb=0.05%, and the balance is Fe. The outer layer is smelted at a temperature of 1590°C. After the composition is up to standard, the temperature is raised to 1630°C and then released for centrifugal casting. The outer layer is made of an overturned iron ladle, and the outer layer is added with the inoculant during pouring. The melting temperature of the core molten steel is 1450°C, and the bottom drain is used. Type molten iron ladle, pouring by adding nodulizer inoculant to the bottom of the ladle. The top of the nodulizer is cove...

Embodiment 2

[0040] Using scrap steel shavings, forged steel heads, ferromolybdenum, ferrovanadium, and electrode powder as raw materials, it is smelted in an intermediate frequency furnace to reach the design composition range of high-speed steel: outer layer molten iron C1.98%, Si1.56%, Mn0.9%, P0.06%, S0.07%, Cr3.59%, Ni2.58%, Mo0.89%, V2.45%, W0.91%, the balance is Fe; core molten iron C2.93%, Si1.32 %, Mn0.75%, P0.06%, S0.08%, Cr0.03%, Ni0.23%, Mo0.25%, W+V+Nb=0.05%, and the balance is Fe. The outer layer is smelted at a temperature of 1550°C. After the composition reaches the standard, the temperature is raised to 1750°C and then it is centrifugally poured out of the furnace. The outer layer is turned over ladle, and the inoculant is added to the bottom of the ladle when pouring. The melting temperature of the core molten steel is 1350°C. Nodulizer inoculant is added to the bottom of the bag, and the steel moisture in the core is poured twice. The first pouring temperature is 1395°C,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com