Polymer powder material for selective laser sintering and preparation method thereof

A powder material, laser sintering technology, applied in the direction of additive processing, etc., can solve the problems of insufficient compactness of parts, affecting the performance of workpieces, low powder loose density, etc., to improve reusability, improve production efficiency, and excellent performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

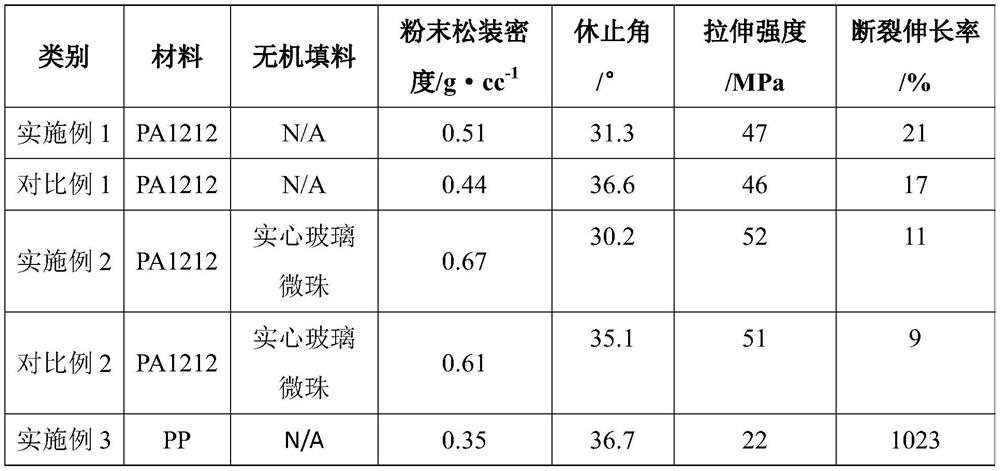

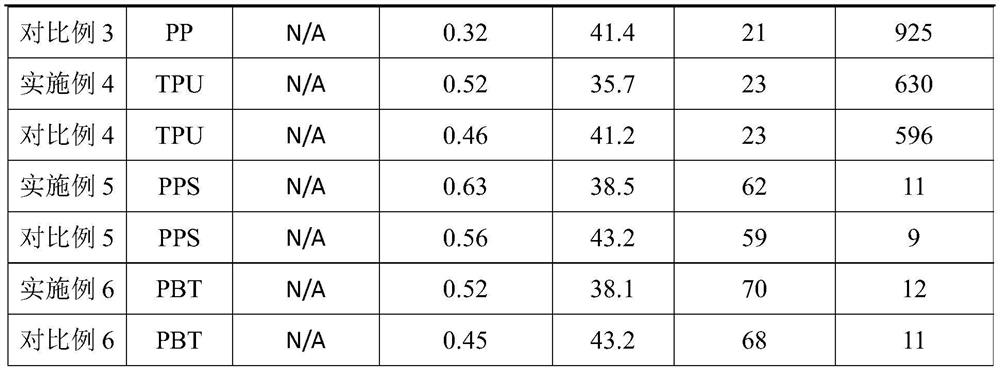

Embodiment 1

[0021] Take 5kg of PA1212 powder with a particle size of 30-120μm, 0.5kg of phosphite antioxidant, and 0.2kg of nano-silicon dioxide into a high-speed mixer, and mix at a speed of 1200RPM for 3 minutes to prepare PA1212 powder. Add 95kg of PA1212 powder with a particle size of 30-120μm into a slow mixer, heat to 80°C, mix at a speed of 50RPM, weigh 0.5kg of water, divide it into 5 parts, each part is 0.1kg, start timing from stirring, Spray the prepared water into the material of the slow-speed mixer every 10 minutes until all the water is added, continue to heat and maintain 80 ° C, stir and mix for 3 hours, and prepare PA1212 powder material, and measure the bulk density of the powder and The angle of repose was printed on the Farsoon HT252 equipment to test the performance of the printed spline.

Embodiment 2

[0025] Take 5kg of PA1212 powder with a particle size of 30-120μm, 0.5kg of phosphite antioxidant, and 0.2kg of nano-silicon dioxide into a high-speed mixer, and mix at a speed of 1200RPM for 3 minutes to prepare PA1212 powder. Add 65kg of PA1212 powder with a particle size of 30-120μm and 30kg of solid glass beads with a particle size of 5-30μm into a slow mixer, heat to 80°C, mix at a speed of 50RPM, weigh 0.5kg of water, divide into 5 parts, each 0.1kg, start timing from stirring, spray the prepared water into the material of the slow mixer every 10 minutes until all the water is added, continue to heat and maintain 80 ° C, stir and mix for 3 hours, The PA1212 powder material was prepared, the bulk density and angle of repose of the powder were measured, and printed on Farsoon Hi-Tech HT252 equipment to test the performance of the printed sample.

Embodiment 3

[0029] Take 5kg of PP powder with a particle size of 30-120μm, 0.5kg of phosphite antioxidant, and 0.2kg of nano-silicon dioxide into a high-speed mixer, and mix at a speed of 1200RPM for 3 minutes to prepare PP powder. Add 95kg of PP powder with a particle size of 30-120μm into a slow mixer, heat to 80°C, mix at a speed of 50RPM, weigh 0.5kg of water, divide it into 5 parts, each part is 0.1kg, start timing from stirring, Spray the prepared water into the material of the slow mixer every 10 minutes until all the water is added, continue to heat and maintain 80°C, stir and mix for 3 hours to prepare PP powder materials, and measure the powder bulk density and The angle of repose was printed on the Farsoon HT252 equipment to test the performance of the printed spline.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com