Method for preparing organic-inorganic photonic crystal composite microspheres in batches

A technology of photonic crystals and composite microspheres, applied in the field of material science, can solve problems such as poor structural stability, affecting structural color, and easy contamination of internal pores, and achieves the effects of low cost, fast preparation, and easy mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

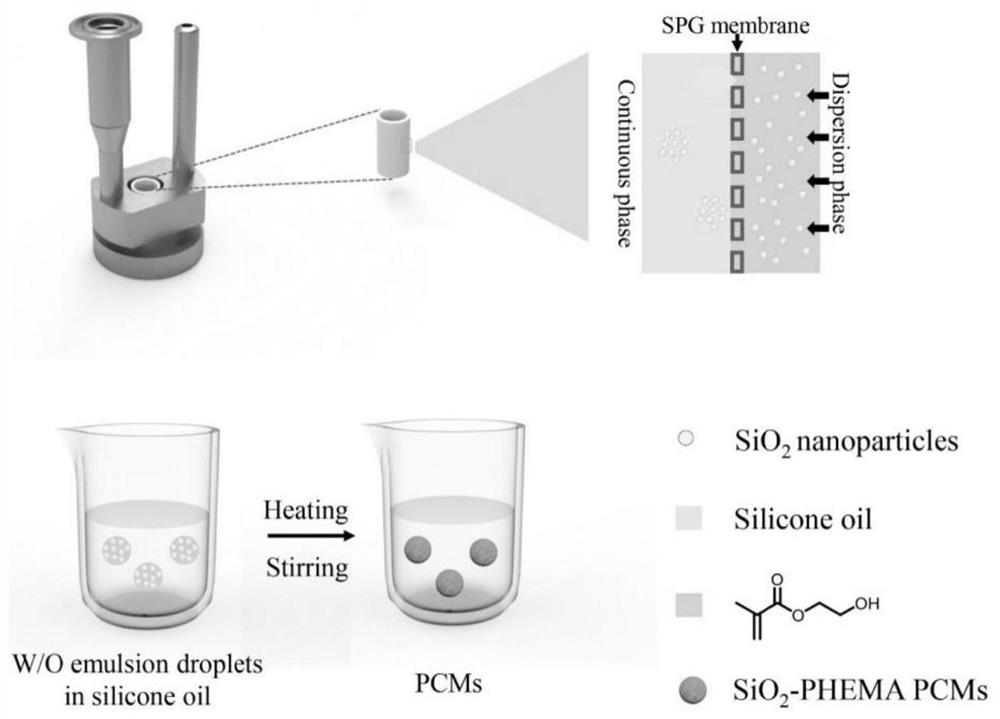

[0042] The preparation process and mechanism of batch preparation of organic-inorganic photonic crystal composite microspheres are as follows: figure 1 shown.

[0043] (1) adopt the improved Methods for the synthesis of monodisperse SiO 2 Monodisperse colloidal nanoparticles: Mix 4.25ml ammonia water, 27.70ml ethanol and 43.05ml deionized water as solution A, and mix 6.75mL tetraethylorthosilicate (TEOS) and 68.25mL ethanol as solution B. After mixing solutions A and B evenly, quickly add solution B into solution A, stir rapidly for 2 minutes, and react at 30°C for 5 hours under continuous stirring. Centrifuge the obtained milky white solution with absolute ethanol for three times, then centrifuge at low speed to remove large particles at the bottom of the centrifuge tube, and then centrifuge at high speed to collect the bottom sediment to remove small particles that have not precipitated in the supernatant, and then dry it twice in a row to obtain SiO with uniform particl...

Embodiment 2

[0053] (1) adopt the improved Methods for the synthesis of monodisperse SiO 2 Monodisperse colloidal nanoparticles: the experimental process is the same as in Example 1, and the particle size is about 235nmSiO 2 For monodisperse colloidal nanoparticles, add 17.80mL of ammonia water to a flask containing 23.40mL of absolute ethanol. After mixing evenly, add 33.80mL of double distilled water. After further stirring evenly, use it as liquid A for subsequent use. Other conditions are the same as in Example 1.

[0054] (2) Preparation of dispersed phase solution and continuous phase solution: weigh 0.02g of prepared SiO 2 The colloidal nanoparticles were dissolved in 2 mL of hydroxypropyl acrylate monomer, dispersed evenly by ultrasonication, and 4 μL of cross-linking agent oxalic acid diacrylate was added, and the amount of cross-linking agent added was 0.2% of the amount of hydroxy acrylate monomer. Add the initiator potassium persulfate of 0.01g again, the initiator add-on is...

Embodiment 3

[0059] (1) adopt the improved Methods for the synthesis of monodisperse SiO 2 Monodisperse colloidal nanoparticles: the experimental process is the same as in Example 1, and the particle size is about 300nm SiO 2For monodisperse colloidal nanoparticles, add 23.80mL of ammonia water to a flask containing 23.40mL of absolute ethanol. After mixing evenly, add 27.80mL of double-distilled water. After further stirring evenly, use it as liquid A for subsequent use. Other conditions are the same as in Example 1.

[0060] (2) Preparation of dispersed phase solution and continuous phase solution: weigh 0.50g of prepared SiO 2 Colloidal nanoparticles were dissolved in 2mL of hydroxypropyl methacrylate monomer, ultrasonically dispersed, and 20 μL of cross-linking agent succinate diacrylate was added. The amount of cross-linking agent added was 1% of the amount of hydroxy acrylate monomer. Add 0.04g of initiator azobisisobutyronitrile, the amount of initiator added is 2% of the amount ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com