Ultralow-temperature single PP recyclable biscuit packaging film and production process thereof

A production process and packaging film technology, applied in the field of ultra-low temperature single PP recyclable biscuit packaging film, can solve the problems of high heat sealing temperature and difficult recycling of packaging films, achieve high heat sealing strength, facilitate recycling and reuse, and improve the overall barrier. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

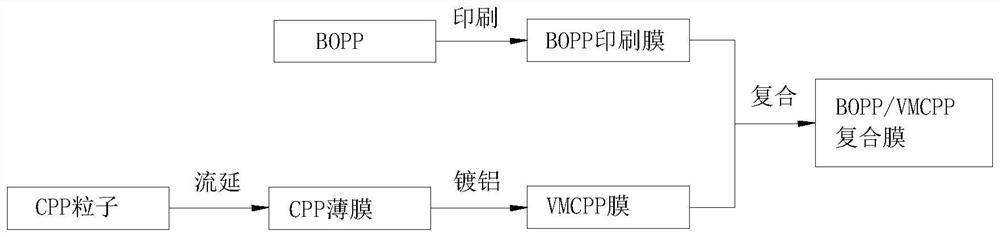

Method used

Image

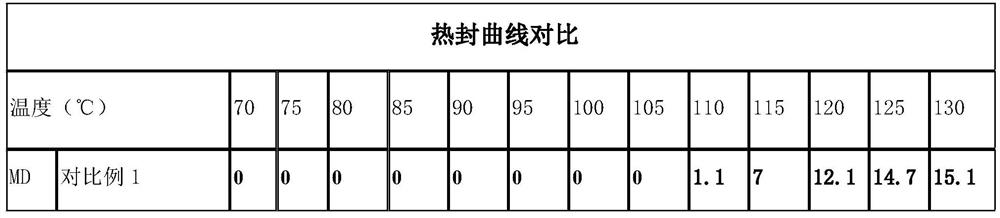

Examples

Embodiment 1

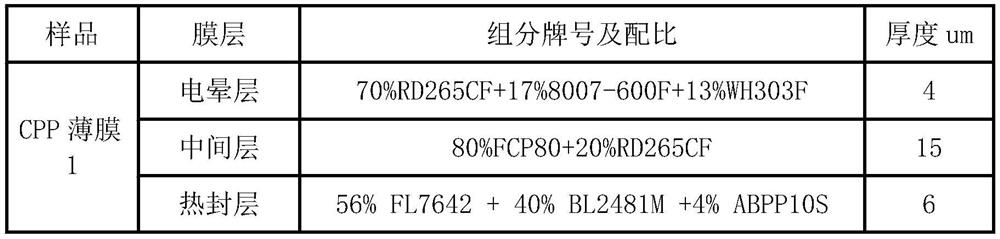

[0030] S1. Casting process: Casting process: according to the formula composition of the VMCPP film in the packaging film, the materials in the corona layer, intermediate layer and heat-sealing layer of the CPP film are weighed according to the stated component ratio, and then the electrical The components of the halo layer, the middle layer and the heat-sealing layer are respectively added to the multi-layer co-extrusion casting machine, and the CPP film is obtained by three-layer co-extrusion molding; after the casting process, the CPP film is cooled and matured Place it for 72 hours and then carry out the treatment of aluminum plating process; during the casting process, high-voltage online corona treatment is carried out during the casting process, so that the surface Diane value can reach more than 38;

[0031]

[0032] Among them, the corona layer is made of binary copolymerized PP particles with the brand name RD265CF produced by Borouge Company, polycycloolefin with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com