Sliding type diesel engine valve clamp

A diesel engine and valve clamp technology, which is applied in the direction of manufacturing tools, grinding workpiece supports, furnaces, etc., can solve problems such as the inability to guarantee the valve stability, and achieve the effect of improving the use effect and improving the stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

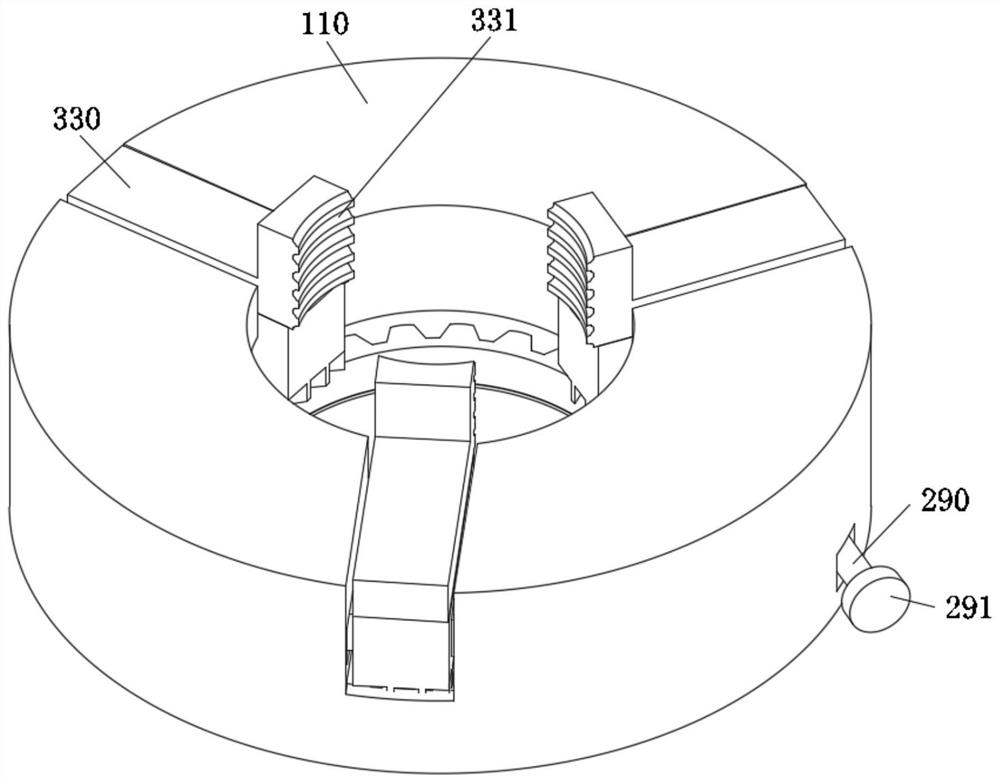

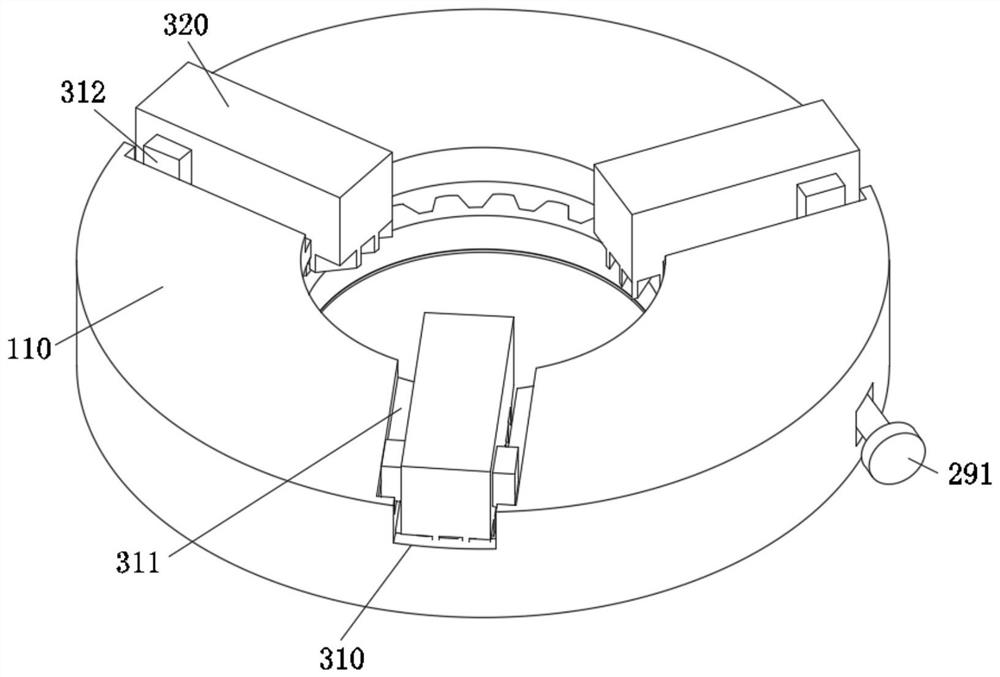

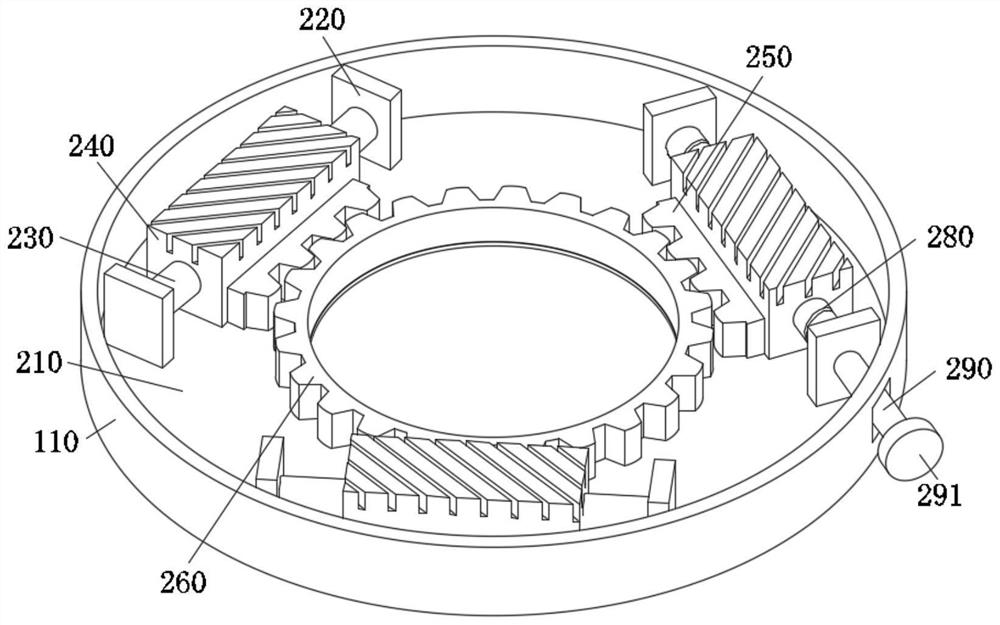

[0033] Such as figure 1 As shown, the shape of the inner side of the clamping block 330 is set as an arc. Through the above-mentioned design, the contact area between the clamping block 330 and the valve stem can be further increased, and the friction assembly includes friction lines 331, and the inner side of the clamping block 330 is opened There are friction lines 331, which can increase the friction force between the clamping block 330 and the valve stem. By increasing the combination of contact area and friction force, the stability of the valve stem after being clamped is greatly improved.

Embodiment 2

[0035] Such as Figure 5 As shown, the main difference of this embodiment is that when the valve head is undergoing heat treatment and shaping, the valve stem needs to move up and down after being centered, the friction assembly includes a fixed side plate 332 and a roller 333, and the inside of the clamping block 330 is fixedly connected with There are two sets of fixed side plates 332, and a roller 333 is connected between the two sets of fixed side plates 332 through a rotating shaft. When the roller 333 contacts the valve stem, the centering of the valve stem is completed, and at the same time, when the valve stem moves up and down, it can drive the roller 333 rotates, thereby reducing the frictional force of the valve stem when moving up and down, ensuring the stability of the valve stem when moving, and reducing the resistance of the valve stem when moving.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com